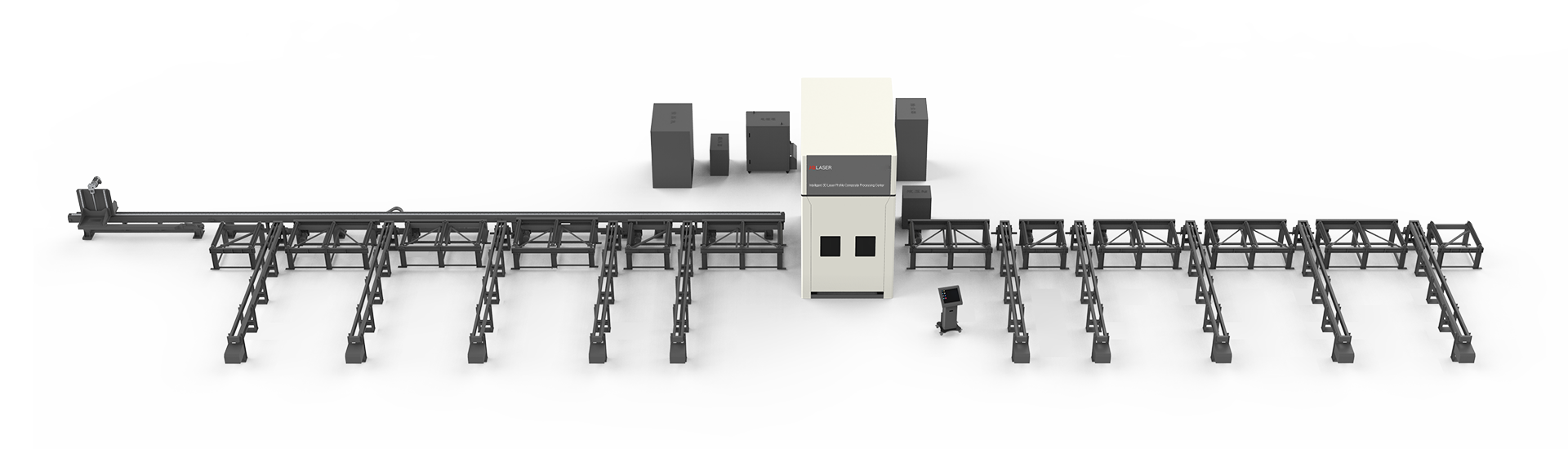

Intelligent 3D Laser Profile composite processing center

Begin on the correct path

H steel, channel steel, angle steel

3D

20000

1000mm*500mm

The best of technology in the smallest member of the family

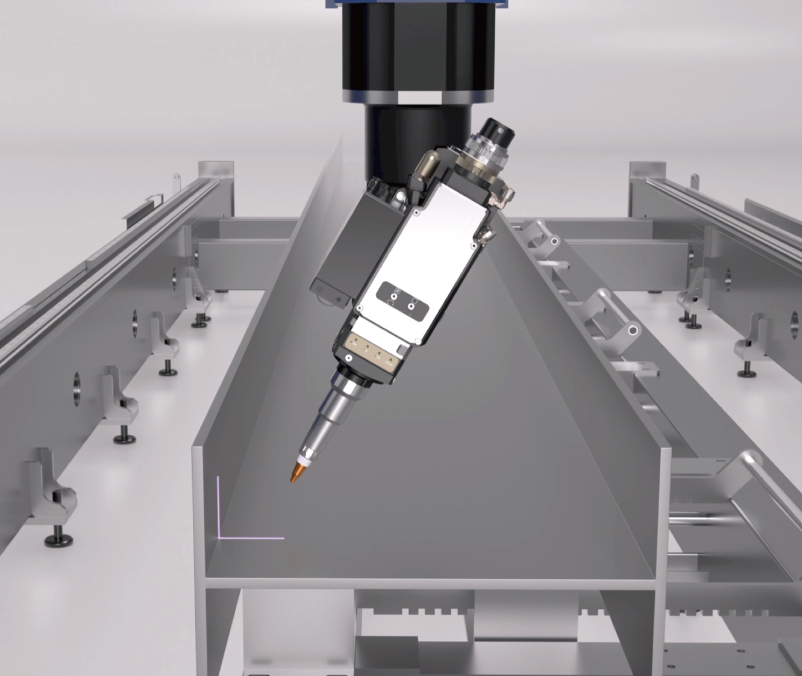

Shape cutting head: 4 series + BC axis + deep finder product portfolio developed for 6~30KW profile cutting applications, air pressure monitoring, lens temperature monitoring, collision prevention and other intelligent technologies are applied. It can meet the processing needs of beam bevel processing, welding notch cutting, bolt hole, etc., and the cutting is stable and the performance is excellent.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

Support multiple automatic loading and unloading, saving labor costs and improving production efficiency.

Automatic loading and unloading of tube up to 20 m in length

Form and content in a single solution

The best choices show their value over time

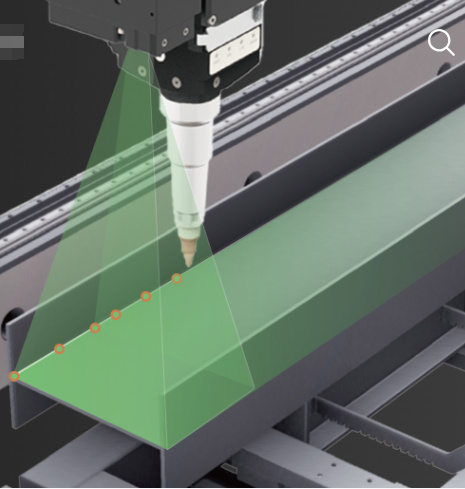

FSCUT’s new profile cutting system FSCUT9200 is equipped with BCW contour scanner. It can effectively detect and compensate for steel deformation types, support various cutting scenarios, and promote the upgrade of production capacity in the steel structure industry through fast graphics and efficient layout.

BCW profile scanner ensures processing precision with real-time measurement and real-time compensation for profile workpiece and drawing deviation. Visually correct.

Correct swing arm model parameters with one click. High accuracy, short time, easy maintenance.

Machine performance will remain robust, reliable and productive year after year.

The software suite that creates value

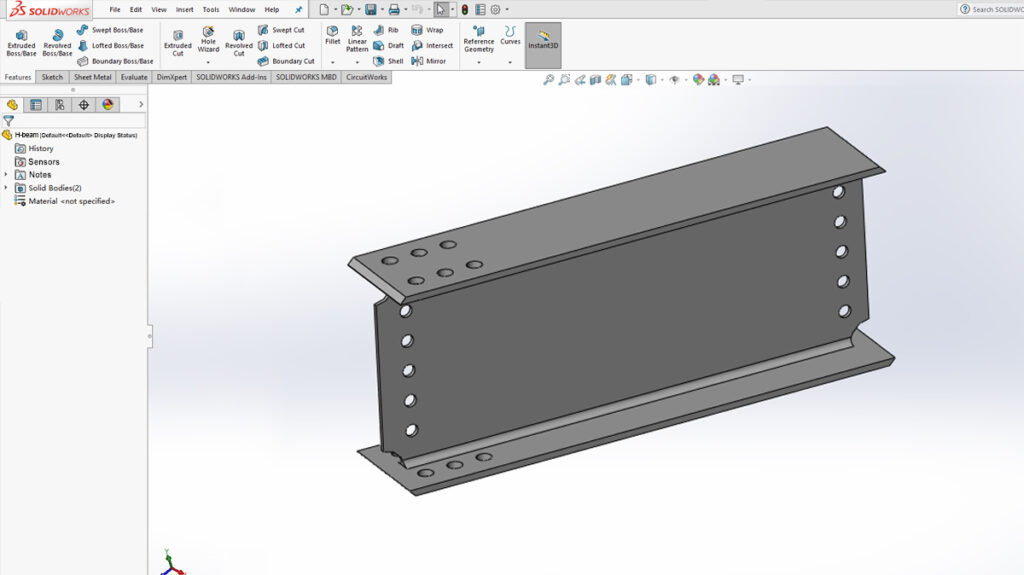

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.