Introduction

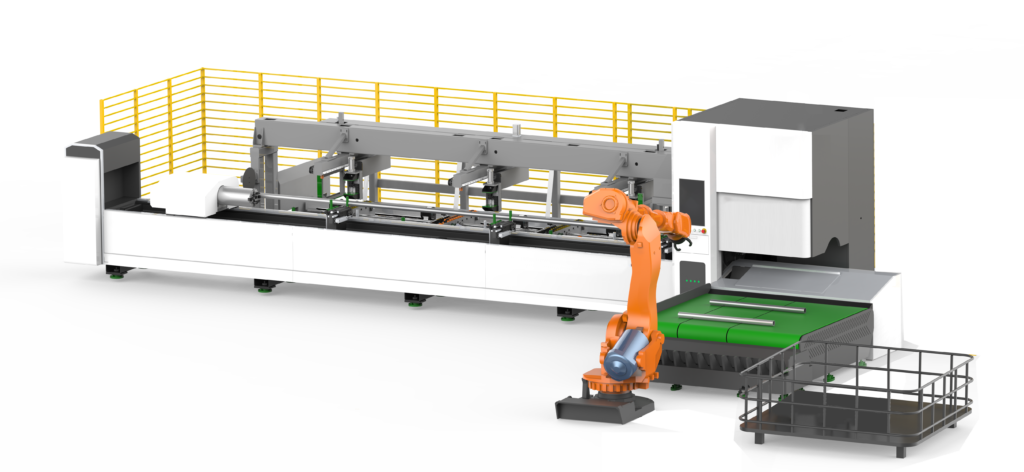

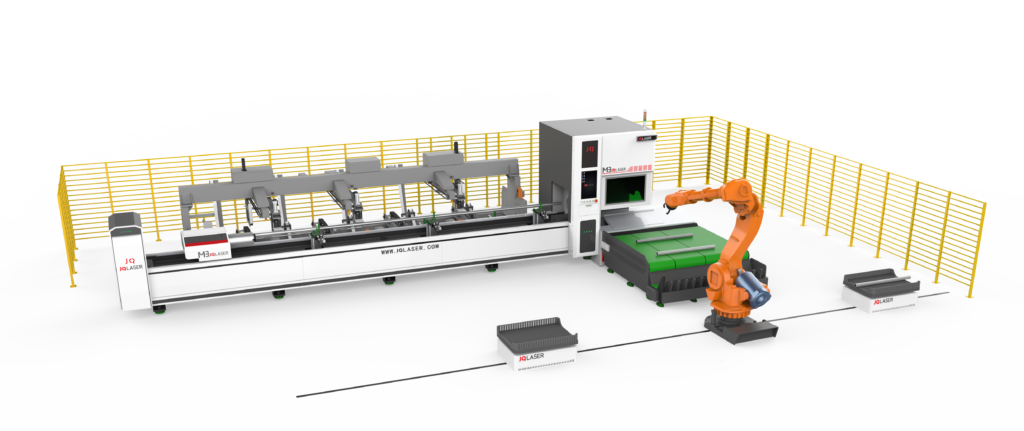

Most modern industries need a reliable and efficient cutting solution for their operations. An automatic storage system for lasertube cutting machines can revolutionize the lasertube cutting experience and offer a range of impressive benefits. This article looks into the seven key advantages of automatic storage systems for lasertube cutting machines.

Revolutionizing the Lasertube Cutting Machine Experience

Automatic storage systems for lasertube cutting machines bring numerous benefits to machining processes. These systems streamline the workflow and experience of using these cutting machines while simultaneously increasing accuracy and precision. These systems eliminate the need for manual loading and unloading which can significantly reduce the amount of time and money associated with a cutting process. Furthermore, the ease of programming ensures that no operator experience is required, saving further money and time in training.

Harnessing the Power of Automation

These storage systems make full use of automation to increase the productivity, efficiency and consistency of the cutting process. These systems ensure that there are no delays from switching from task to task or from operator to operator as there is no need for manual input. These systems can be programmed to tackle a variety of cutting needs and tasks including intricate shapes, long lines and small trapezoids with ease and accuracy.

Making the Most of Your Machining Process

With automatic tube storage systems, you can make the most of your lasertube cutting machine. By eliminating manual labor, these systems free up operator time, allowing them to focus on higher value tasks. This means that you can optimize your machine’s output, get the most out of your raw materials, adjust cutting processes and execute complex cutting applications better while also lowering labor costs.

Increasing Efficiency, Enhancing Quality

Automatic tube storage systems are designed to facilitate more efficient cutting processes. These systems increase cutting speed, reduce cycle times and increase quality. Thanks to their design and the use of the latest technologies, they can achieve temperature stability, reduce warped pieces and ensure consistent accuracy throughout the cutting process.

Enhanced Material Management

One of the primary benefits of integrating an automatic storage system with a Lasertube cutting machine is enhanced material management. These systems can store raw materials efficiently, ensuring that they are readily available when needed. This eliminates the need for manual material handling, reducing the risk of errors and ensuring a continuous workflow.

Optimized Production Workflow

The integration of automatic storage systems streamlines the production workflow. When materials are readily accessible, production processes can run smoothly without unnecessary interruptions. This optimization leads to increased productivity and quicker turnaround times, which can be a significant competitive advantage.

Optimizing Operator Safety

The use of these systems also helps to streamline operator safety protocols. Automatic tube storage systems are designed to be safe for operators to use, eliminating the need for manual handling of sharp or sharp edged tubes. By implementing these systems, there is no need to worry about operator injuries or delays related to operator or equipment handling.

Streamlining Troubleshooting Protocols

When something goes wrong with a lasertube cutting machine, it can be time consuming to troubleshoot the issue. Automatic storage systems for lasertube cutting machines can help simplify the troubleshooting process. These systems are designed to provide real-time feedback so that operators can quickly identify and address any issues. This can minimize downtime and make the entire cutting process much more efficient.

Decreasing Cycle Times and Waste

The use of automatic storage systems can also help reduce cycle times and waste. These systems are designed to improve the overall cutting process and provide operators with the ability to track cutting progress in real-time. This can help operators adjust the cutting speed and plan for the use of raw materials more efficiently. This can help you make the most of your raw material and reduce the amount of waste.

Unlocking New Possibilities with Automatic Storage System

Finally, the introduction of automatic storage systems can unlock a variety of new possibilities. These systems can simplify tasks and processes, saving operators time and money. This can result in enhanced creativity, allowing operators to experiment with alternate cutting techniques and create new, complex shapes.

Conclusion

In conclusion, automatic storage systems for lasertube cutting machines bring a wealth of benefits to machining processes. These systems revolutionize the lasertube cutting experience, harness the power of automation, streamline troubleshooting protocols and more. With an automatic storage system, operators can reduce cycle times, minimize waste and unlock new possibilities.