Introduction

Tube laser cutting machines are highly precise, efficient and versatile tools used in large industrial and manufacturing contexts. More and more companies are discovering the advantages of tube laser cutting machines in terms of cost-saving, precision and flexibility. In this article, we will explore the 8 reasons for choosing a tube laser cutting machine.

All About Tube Laser Cutting Machines

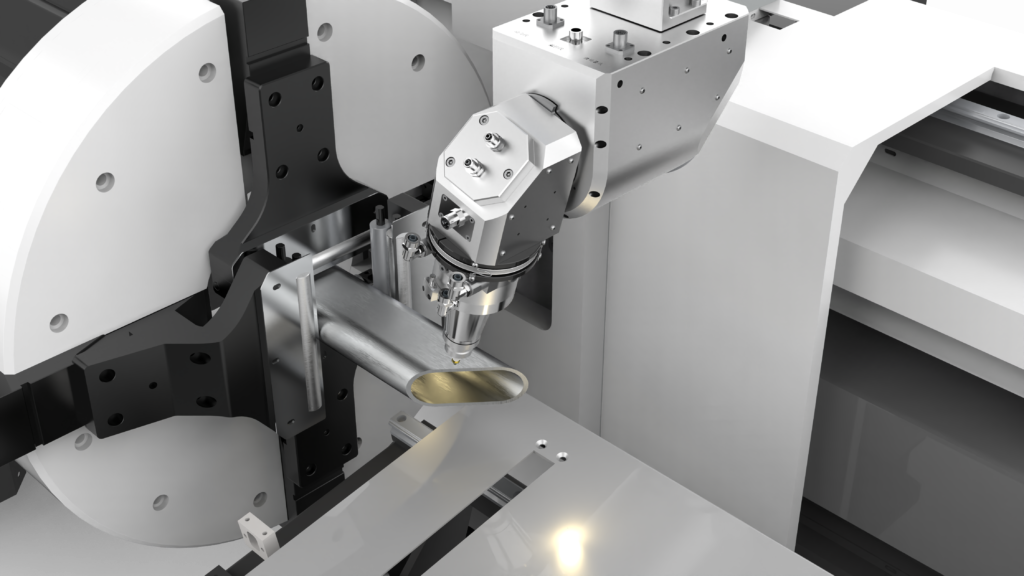

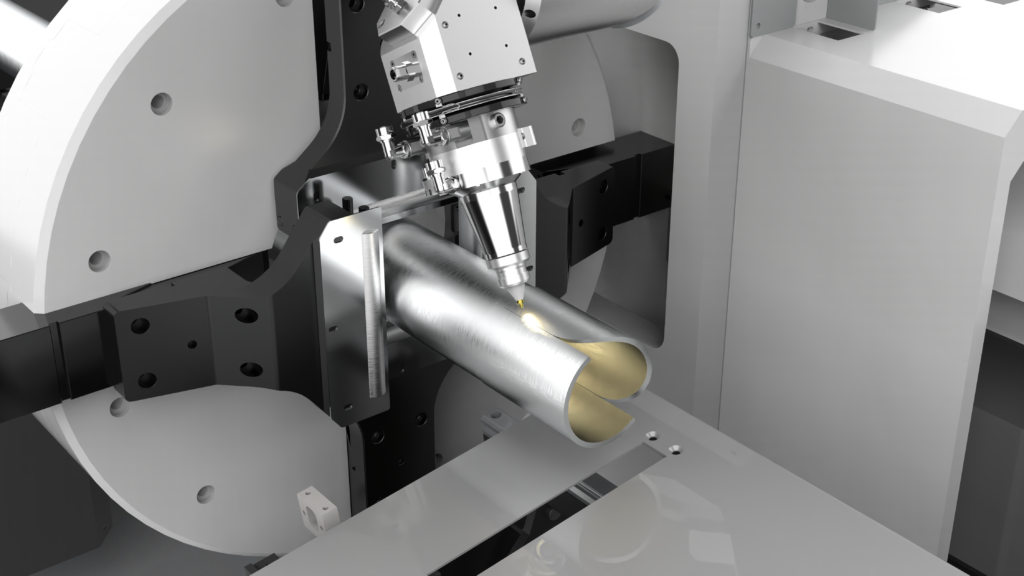

A tube laser cutting machine is an automated computer-controlled device that uses lasers to cut or form any type of material into custom or standard shapes. It typically uses a double laser beam to make precise cuts, ensuring accurate parts every time. Unlike traditional cutting techniques, the laser has no contact with the workpiece, allowing for both intricate designs and smooth edges with no additional finishing required.

1. Precision and Accuracy

One of the primary reasons to choose a tube laser cutting machine is its exceptional precision and accuracy. These machines utilize high-powered lasers to make cuts with microscopic precision, ensuring that every piece is manufactured to exact specifications. Whether you’re producing intricate components or simple shapes, precision is key, and tube laser cutting delivers it consistently.

2. Versatility

Tube laser cutting machines are incredibly versatile and can work with a wide range of materials, including steel, aluminum, copper, and more. Moreover, they can cut complex shapes and patterns with ease. This versatility allows for greater design freedom and innovation in your products.

3. Speed and Efficiency

Time is money in the world of manufacturing. Tube laser cutting machines operate at high speeds, significantly reducing production time compared to traditional cutting methods. This efficiency not only boosts productivity but also leads to substantial cost savings over time.

4. Minimal Material Waste

Traditional cutting methods often result in significant material waste due to the width of the cutting tool. Tube laser cutting minimizes waste by making precise cuts, making it an environmentally friendly and cost-effective choice for metal fabrication.

5. Intricate Designs

Do you need to create intricate designs or patterns in your metal components? Tube laser cutting machines are well-suited for this task. They excel at producing detailed and complex shapes that might be challenging or impossible to achieve with other cutting methods.

6. Integration with Automation

In today’s era of automation, tube laser cutting machines can be seamlessly integrated into automated production lines. This integration reduces the need for manual labor and enhances overall efficiency, making it an ideal choice for high-volume manufacturing.

7. Safety

Safety is a paramount concern in any manufacturing environment. Tube laser cutting machines come equipped with advanced safety features, including enclosures, interlocks, and laser safety protocols, to protect operators and maintain a secure working environment.

8. Cost-Effectiveness

Conclusion

Tube laser cutting machines offer a range of benefits, from cost-efficiencies to precision and speed. They are perfect for companies that are looking for a versatile and high-performance cutting method. Whether the task is simple or complex, a tube laser cutting machine can provide high accuracy, efficiency, safety and quality results. As such, it is an overall smart investment for any company.