Introduction

Tube lasers are engineered and programmed to cut metal with precision and accuracy. This cutting-edge technology is revolutionizing how we manufacture H-beams, allowing businesses to save time, money, and resources. Read on to discover the benefits of tube lasers over manual cutters and find out if they’re the right choice for your business’s H-beam needs.

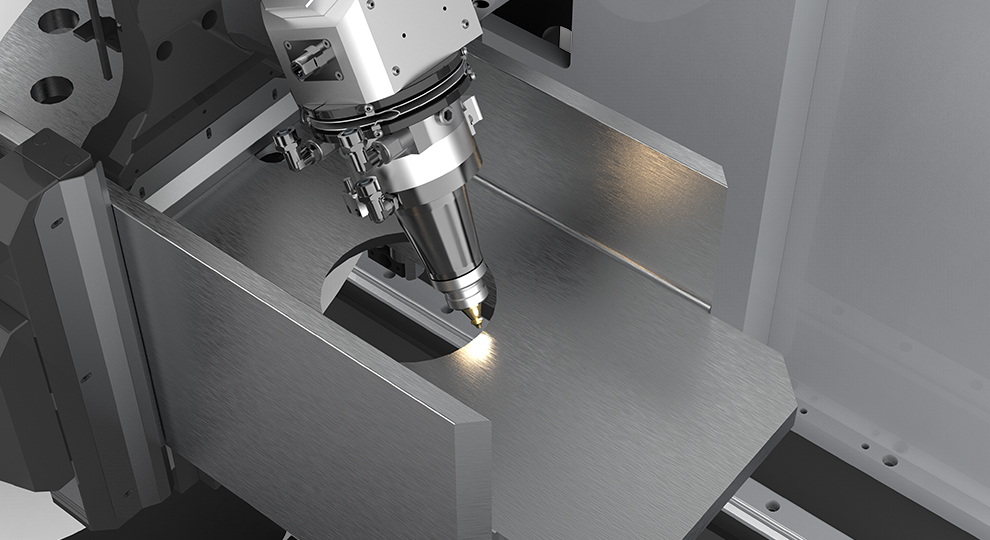

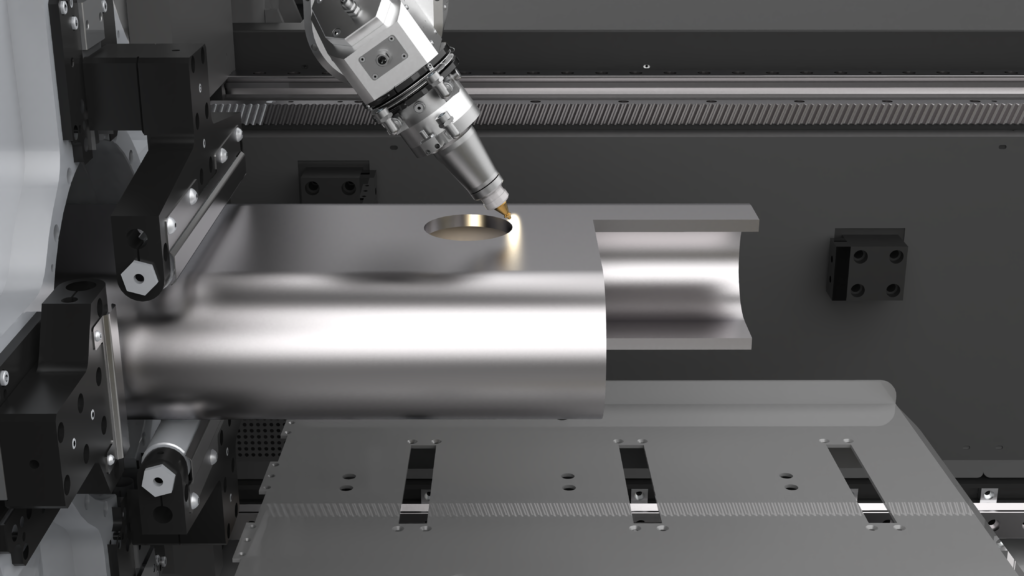

Defining the Perfect Cut: Tube Lasers Put Precision to the Test

Tube lasers create precise, accurate and repeatable cuts through metal H-beams with a level of efficiency and perfection that’s impossible for manual cutters. What makes these machines so beneficial for metal manufacturing is their ability to cut complex shapes with precise accuracy in a fraction of the time it would take for manual cutting. This means that businesses no longer have to worry about cutting errors and inconsistencies, since tube lasers can produce the perfect cut every single time.

Cutting-Edge Technology for Manufacturing H-Beams

Tube lasers offer the latest in metal cutting technology and are equipped with advanced programming capabilities. By programming a tube laser, businesses can determine how their H-beam should be cut and then the machine automatically follows the instructions. This makes the entire process easier and faster, enabling businesses to produce a large number of consistent H-beams that meet their production needs.

Saving Time, Money and Resources with Tube Lasers

Manufacturing H-beams with tube lasers also helps businesses save time, money, and resources. Instead of manually cutting the metal which can be a lengthy process, tube lasers make quick work of it. In addition, tube lasers consume far less energy than manual cutters which helps businesses reduce their energy consumption and costs.

An Accurate Edge: How Tube Lasers Out-Perform Manual Cutters

There are a few key advantages that help tube lasers out-perform manual cutters. First and foremost, tube lasers have a higher degree of accuracy and precision due to their automated capabilities. They make it easy for businesses to consistently produce H-beams with smooth edges and perfect cuts. Additionally, tube lasers are also easier to handle and require minimal manual intervention.

Are Tube Lasers Beneficial for Your Business?

Having a tube laser in the workplace can be beneficial for a variety of businesses. Tube lasers are ideal for businesses that are looking to reduce their production time and costs, since they are proven to be more efficient and require less manual labor. Additionally, tube lasers can also help businesses produce high-quality H-beams with precise accuracy and repeatability.

Achieving High Accuracy and Precision with Tube Lasers

Tube lasers are engineered with high-precision cutting abilities that make it possible for businesses to achieve outstanding accuracy and precision. Each cut is defined through programming, which is then followed by the laser to create an exact replica each and every time. This provides businesses with an effective and cost-efficient way to produce H-beams with top-notch accuracy.

Reduce Material Waste and Increase Yield with Tube Lasers and H-Beams

Tube lasers also help businesses reduce material waste and increase their yield. Because the cuts are precise, businesses can be confident that the H-beams will be perfectly cut and nothing will be wasted. This allows businesses to save money and resources, since they don’t need to worry about faulty cuts or material waste.

The Cost-Benefit of Utilizing a Tube Laser Cutter

The cost-benefit of utilizing a tube laser cutter is clear: businesses save time, money, and resources in the long-run. Not only are these machines able to produce consistent H-beams with amazing accuracy, but they also help businesses reduce energy consumption and material wastage.

Making the Most of Your Investments with a Tube Laser System

When it comes to making the most of your investments, a tube laser system is a smart choice. These machines are built tough and boast impressive capabilities that can provide long-term savings. In addition, businesses can take advantage of the tube laser’s features and programming capabilities, allowing them to create complex shapes and custom cuts with ease.

Conclusion

Tube lasers are essential tools for businesses that need to produce H-beams with precision. By utilizing this cutting-edge technology, businesses can save time, money and resources, as well as reduce waste, increase their yield, and create perfect cuts with ease. Plus, with its impressive precision, accuracy, and cutting capabilities, businesses can confidently rely on the tube laser for all of their H-beam needs.