Bevel cutting

Laser tube cutting machine beveling cutting is a processing method that cuts materials into a bevel shape with an inclined or beveled angle. This technology is widely used in many industries, especially in situations where high precision and high efficiency are required.

Definition of laser tube cutting machine beveling cutting

Laser tube cutting machine beveling cutting achieves bevel cutting of metal materials by adjusting the angle between the laser beam and the original surface to less than 90°. This technology can complete the processing of multiple bevel types in one operation, such as V-type, Y-type, X-type and K-type bevels, greatly improving processing efficiency and accuracy

Application

Beveling before welding: Before metal welding, beveling helps to improve the strength and quality of the welded joint. The laser cutting machine can accurately cut the required bevel shape to meet different welding requirements.

Steel structure processing: Laser cutting machines can be used to manufacture and process bevels in steel structures, such as steel bridges, steel buildings, steel beams, etc. Through bevel cutting, optimized joining and connection can be achieved to ensure the stability and safety of the structure.

Pipeline manufacturing: In the pipeline manufacturing process, bevel cutting is used to achieve the connection of pipelines and the precise matching of joints to improve the quality and efficiency of pipelines.

Beveling before solution cladding: In solution cladding, bevel cutting helps to better fuse the laser cladding layer and the substrate.

Automobile manufacturing: Laser cutting machine bevel cutting is used in automobile manufacturing to cut the bevel of automobile parts, such as body panels and suspension system parts.

Shipbuilding: In shipbuilding, laser cutting machine bevel cutting is often used to cut the bevel of hull plates to achieve the connection of hull plates and the bevel sealing of joint structures.

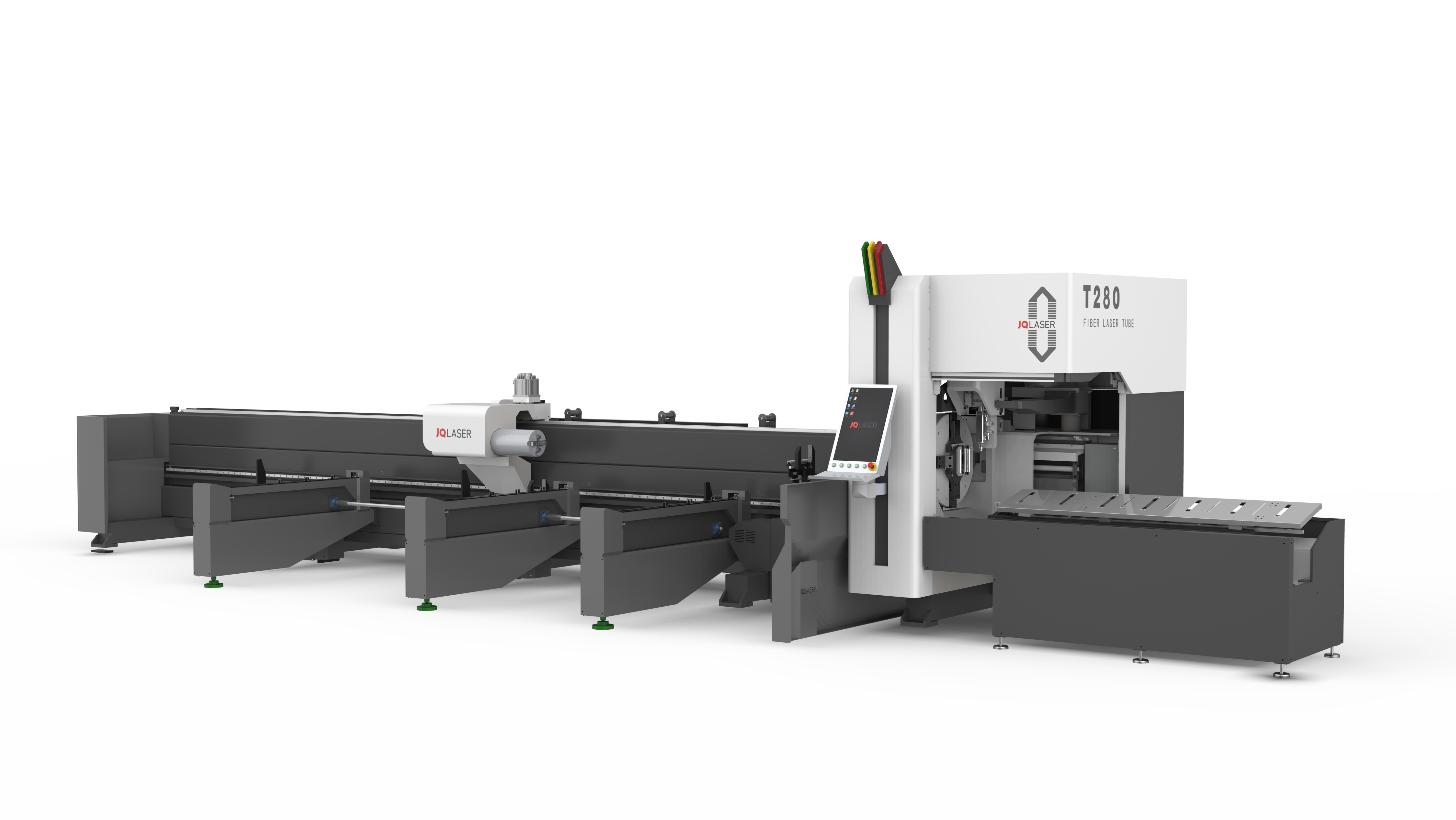

Recommended Products