Introduction

The use of tube laser cutting technology has revolutionized many industries, offering manufacturers a cost-effective way to work with complex designs and achieve optimized cutting performance. Now, with the innovative introduction of bevel cutting technology, businesses can take their applications to the next level. In this article, we will explore the potential of bevel cutting with tube laser cutters, unveiling its many benefits and the automation options that are available.

Unlocking the Potential of Tube Laser Cutting: An Innovative Approach

Tube laser cutting is an incredibly versatile process that can be used to produce intricate designs with high accuracy and speed. By combining the latest cutting technology with an optimized cutting head design and advanced features, manufacturers can unlock new possibilities in the production of components and pieces that are used in the automotive, aviation, and energy industries. The core concept of tube laser cutting is to produce components and pieces with tubes instead of other materials such as steel or aluminum.

Introducing Revolutionary Tube Laser Cutting Technology

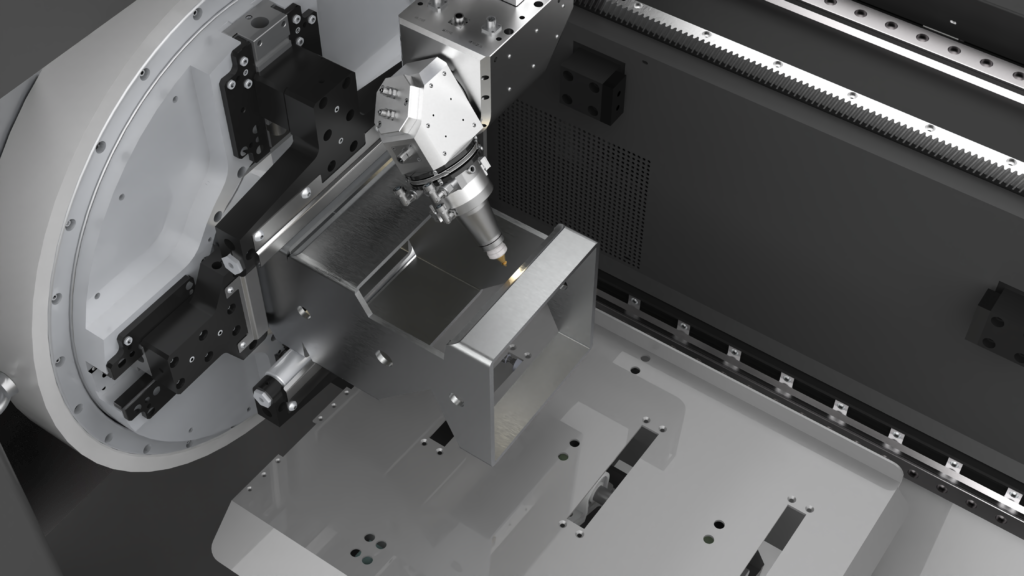

Tube laser cutting technology offers various advantages for manufacturers, including the ability to process complex and intricate shapes with speed, precision, and accuracy. Unlike traditional cutting techniques, tube laser cutters feature a cutting head that can move in both the X and Y axes and is capable of cutting through a variety of material thicknesses with minimal operator input. Additionally, this type of cutting technology uses fewer tools and generates fewer waste products.

Applying Precision and Accuracy to Tube Laser Cutting

The accuracy of tube laser cutting technology makes it a great option for creating detailed components that require high levels of precision. With a tube laser cutter, manufacturers are able to produce components with intricate shapes and angled edges that would be difficult to create with traditional cutting techniques. Additionally, the automated nature of tube laser cutting allows for faster production times and improved workflows.

Unveiling the Benefits of Tube Laser Cutters

The benefits of using tub laser cutters for precision cutting is unrivaled. With this type of cutting technology, it is possible to produce components in difficult to access areas and those with complex geometries. Additionally, tube laser cutters are highly versatile, able to cut a range of materials with a single machine.Moreover, tube laser cutters offer increased safety, as they can be automated to handle hazardous materials without exposing operators to harm.

Redefining Productivity in Tube Laser Cutting

By combining the advantages of laser cutting and tube laser technology, manufacturers can achieve unprecedented levels of productivity. The automated nature of tube laser cutters allows them to work at exceptionally faster speeds than their manual counterparts. Additionally, they are capable of performing tasks with a high level of accuracy and precision, improving the quality of the final product. Furthermore, the use of this technology can significantly reduce production costs, as it eliminates the need for manual labor.

Exploring the Advantages of Bevel Cutting with Laser Technology

Bevel cutting is a process in which components are cut at an angle or with a curved edge. This type of cutting is used to create components and pieces that require intricate shapes and dimensions, such as those used in automotive, aerospace, and energy industries. With laser technology, bevel cutting is made easier and more precise than ever before.

Taking Laser Cutting to the Next Level with Bevel Cutting

Bevel cutting with laser technology offers manufacturers a range of benefits that cannot be achieved with traditional cutting techniques. Using laser cutting for beveling results in finer finishes and fewer burrs, allowing for easier post-processing. Additionally, the cutting speed can be adjusted to produce components with a lower heat-affected zone. These features enable manufacturers to produce intricate components more efficiently and accurately.

Achieving Diversified Output with Tube Laser Cutters

Tub laser cutters are capable of creating components and pieces with a more varied output than traditional cutting techniques. By incorporating bevel cutting technology, manufacturers have the ability to create complex components without compromising on accuracy or precision. Additionally, this type of laser cutting technology can be used to create intricate holes, slots, and other details that require high levels of creativity and detail.

Unleashing the Power of Automated Bevel Cutting

By leveraging the capabilities of automation, manufacturers can unlock the potential of tube laser cutting, allowing them to achieve even greater levels of productivity and accuracy. Automation plays a critical role in bevel cutting, as it eliminates the need for manual intervention and enables the machine to be programmed to produce parts with precision, speed, and accuracy.

Maximizing Efficiency with Optimal Bevel Cutting Solutions

By utilizing the automation capabilities of tube laser cutters, manufacturers can maximize efficiency and precision when producing components with beveled edges. With this technology, it is possible to produce components that require a high level of detail, such as automotive and aerospace parts, with greater speed and efficiency. Additionally, automated bevel cutting technologies offer improved control over the cutting output ensuring high-quality results in shorter production cycles.

Unmatched Versatility: Unlocking Design Possibilities

Gone are the days of conventional cutting methods limiting design possibilities. The Tube Laser Cutter, with its bevel cutting innovations, empowers designers and engineers to explore uncharted territories in product development. Whether it’s creating seamless joints for intricate metal frameworks or crafting precise contours for industrial components, the versatility of the Tube Laser Cutter makes it an indispensable tool for pushing the boundaries of creative engineering.

Boosting Productivity: Efficiency Redefined

In the fast-paced world of manufacturing, every second counts. The Tube Laser Cutter’s bevel cutting capabilities significantly expedite the production process, minimizing manual labor and maximizing output. With its high-speed precision cutting and seamless automation, it ensures that deadlines are met without compromising on the quality of the end product. This efficiency boost translates into reduced costs and increased profitability for businesses, making it a vital asset for any forward-thinking manufacturing setup.

Seamless Integration: Bridging the Gap Between Design and Execution

The integration of bevel cutting through the Tube Laser Cutter facilitates a seamless transition from design concepts to the final product. Its advanced software compatibility enables the translation of intricate designs into tangible outputs with unmatched precision. This seamless integration streamlines the manufacturing workflow, reducing the likelihood of errors and ensuring a smooth and efficient production cycle.

Conclusion

Overall, tube laser cutting offers an attractive alternative to traditional manufacturing processes. By introducing bevel cutting technologies, manufacturers are now able to produce components with intricate shapes and complex geometries with accuracy and speed. Furthermore, the automation capabilities of tube laser cutters allow for improved productivity and efficiency, enabling manufacturers to produce components with greater consistency and quality. As a result, the use of tube laser cutters is becoming increasingly popular in a wide range of industries.