Introduction: Tube cutting is a vital process in the fabrication and manufacturing industries. Automated tube cutting systems offer a host of advantages over manual cutting and are becoming increasingly popular for improving efficiency and output. This article will explore the advantages of automated tube cutting systems and discuss the ways businesses can get the most out of them.

Unlocking the Efficiency Benefits of Automated Tube Cutting

Automated tube cutting machines offer numerous advantages over manual cutting operations. Most notably, they drastically reduce the amount of labor and material required to cut tubes, pipes, and other materials. Moreover, automated machines can be highly precise and can make finer cuts than what is possible with manual equipment, eliminating the need for secondary finishing operations. Not only can automated cutting machines increase production speed, but they also reduce waste, as they eliminate costly overcutting. Furthermore, these machines are less prone to operator error than manual processes, which can add to the overall efficiency gains of automation systems. Automating the tube cutting process can also free up personnel to focus on system monitoring and other more productive tasks.

Deploying Automated Solutions for Increased Performance

Automated solutions are quickly becoming the preferred option in the manufacturing and fabrication industries due to their ability to improve performance and reduce costs. Automated tube cutting machinery is no exception and provides the potential for reducing labor costs as well as improving lead times, quality, and accuracy. Moreover, having a system in place that is reliable and provides consistent output can empower businesses to better manage production costs.

Streamlining System Reliability with Automated Cutting

Another key advantage to automated tube cutting is that these systems are more reliable than manual processes. With automated systems, businesses can be assured that their cuts will be consistent and accurate every time and can be tailored exactly to their specifications. Automated systems also feature up-to-date components, and their performance is monitored in real time. This ensures maximum uptime and mitigates any potential downtime that could occur with manual processes.

Improving Tube Cutting Accuracy with Automation

A key benefit of automated tube cutting systems is their improved accuracy and precision. Automated systems are able to cut extremely precise and intricate profiles that would be difficult or impossible to replicate manually. This improved accuracy enables the edge quality to be much smoother when compared to manual operations and helps to reduce the need for second finishing operations. Moreover, automated systems are less prone to errors due to human error, and they can be easily adjusted and tuned to get the desired output.

Reducing Cycle Times and Waste with Automation

Automated tube cutting systems significantly reduce cycle times and waste compared to manual processes. These systems are capable of making repeatable and accurate cuts, each time cutting down on the cycle time and the amount of wasted material. Automated systems also enable businesses to save on labor costs due to its ability to run with fewer operators since it does not require as much manual labor.

Exploring the Financial Benefits of Automated Tube Cutting

In addition to cutting cycle times and waste, automated tube cutting systems also provide potential cost savings from a financial standpoint. By eliminating the need for costly manual labor, businesses can drastically reduce labor costs associated with manual cutting operations. Automated systems also generally require lower capital costs due to their lighter weight and cheaper components. Furthermore, automated systems are more reliable, which helps to reduce maintenance costs.

Enhancing Quality with Automated Solutions

Not only can automated tube cutting systems reduce cycle times and waste, they can also improve quality when compared to manual operations. As automated systems provide a much more precise cutting experience, operators are assured of consistent and clean cuts without any distortion. This minimizes the need for secondary finishing operations and improves the overall quality of the final product.

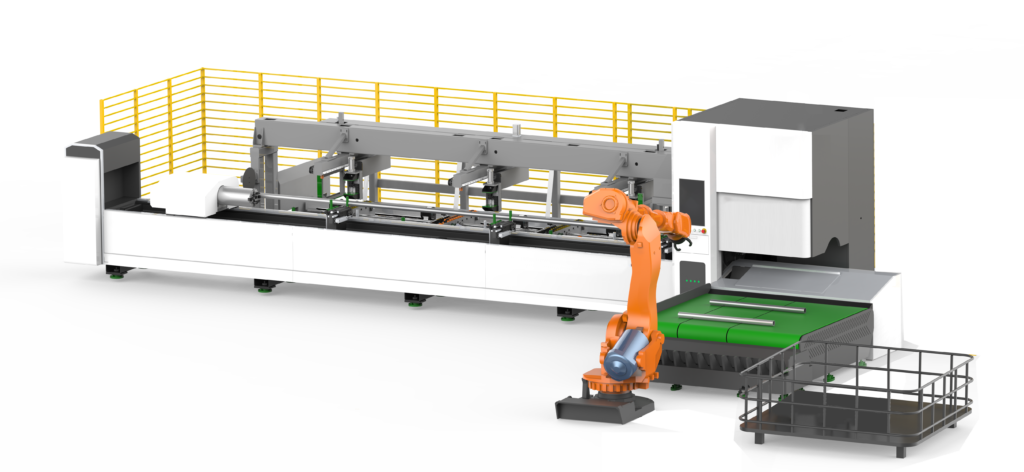

Utilizing Robotic Capabilities for Greater Effectiveness

Robotics can also be employed to increase the effectiveness of automated tube cutting systems. By employing robotic arms and sensors, businesses can drastically improve the speed and accuracy of the tube cutting process. Robotics will allow for an even more precise cutting experience and can reduce the amount of time required for the cycle time. Furthermore, robotics provide greater flexibility, enabling businesses to cut a wide variety of shapes and sizes with minimal touch up.

Choosing the Right Automation Technology for Tube Cutting

The type of automation technology needed for tube cutting operations will depend on the size and complexity of the parts being cut. Automated systems generally feature components such as lasers, water jets, and plasma torches that can cut any type of metal or other material depending on the application. For smaller cuts with higher accuracy, lasers will be the optimal choice, while water jets or plasma torches are best suited to larger or thicker materials.

Implementing Automation for Optimizing Tube Cutting Output

Businesses need to take a few steps when implementing automation for tube cutting operations. First, businesses should identify any potential weak points in the existing process and determine how automation would best fit in. Additionally, they need to consider the budget and figure out what type of automation technology will best suit their needs. Once the automation system is in place, businesses should focus on optimizing the output, ensuring consistent and accurate tube cutting. Conclusion: Automated tube cutting machines provide numerous advantages for businesses in the manufacturing and fabrication industries—from reducing labor costs to improving accuracy and quality. By harnessing the power of automation, businesses can drastically improve their efficiency and output. Although the installation of automated systems can be costly, they more than make up for it in capability and performance, making them an increasingly attractive option for businesses looking to increase their output.