What Makes Fiber Lasers Special and Expensive Compared to CO2 Lasers?

Introduction to Fiber Lasers Fiber lasers represent a significant advancement in laser technology, distinguished by their unique design and operational principles. A fiber laser uses an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, or dysprosium as its active gain medium. The design of fiber lasers allows for a high degree of […]

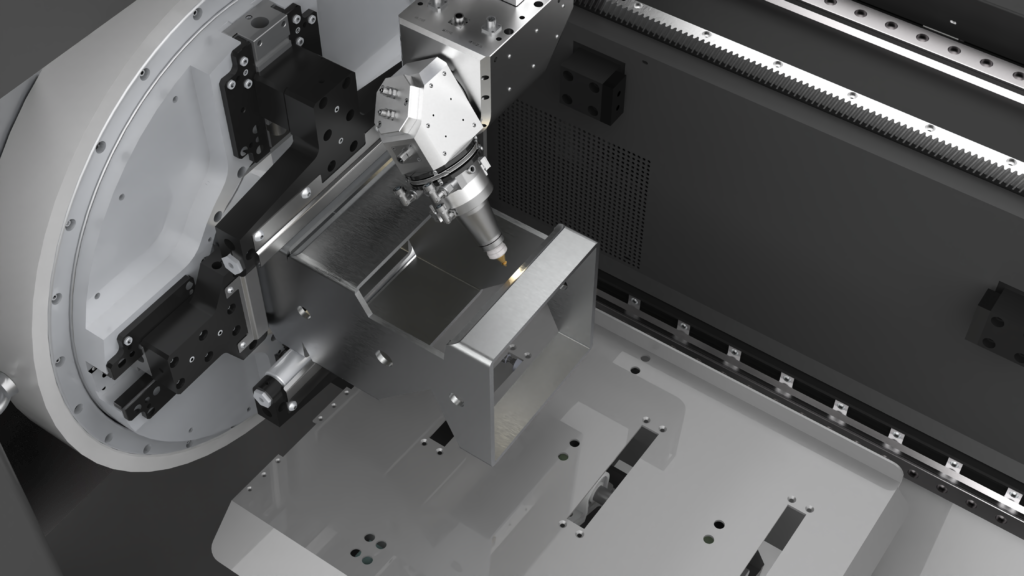

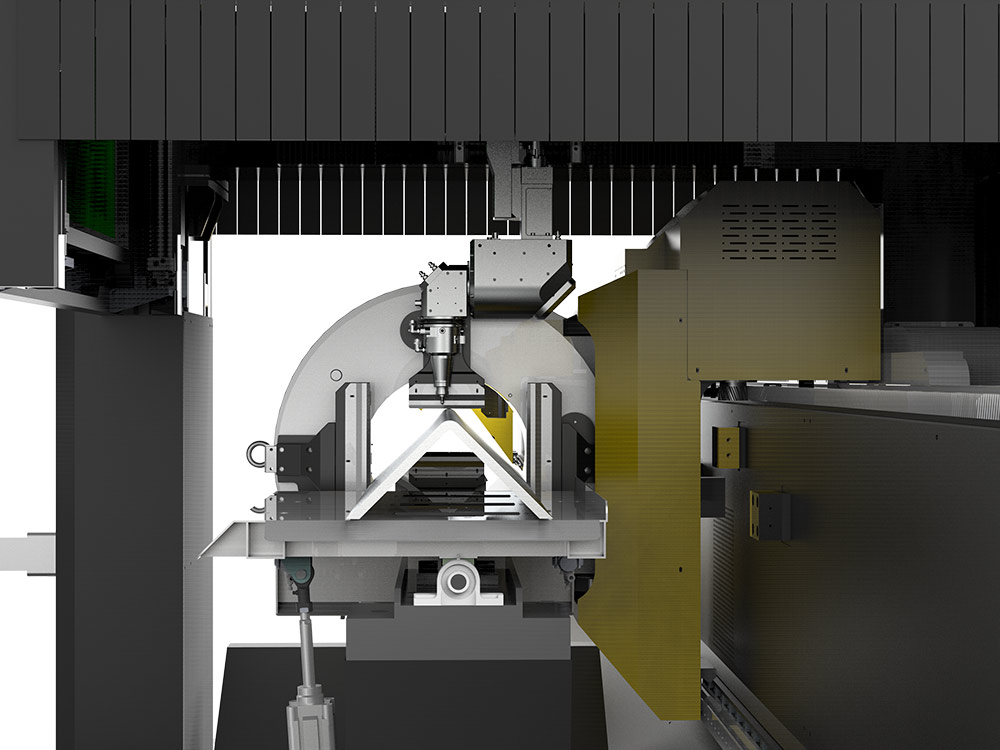

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN Introduction The integration of advanced laser tube cutting machines like the FLT-6035ETN into modern manufacturing processes marks a significant technological advancement. These machines epitomize precision, efficiency, and versatility in metal fabrication. However, their sophisticated nature necessitates a strategic […]

Methods to extend the service life of industrial welding machine lasers

The reason why welding machine lasers are easily damaged. The laser cutting process uses high-power and high-density laser beams to scan the surface of the workpiece and locally heat the material to thousands or even tens of thousands of degrees Celsius in a very short time, so that the irradiated material can quickly vaporize and […]

Application of laser cutting technology in machinery manufacturing

Main types of laser cutting technology Vaporization cutting Vaporization cutting is the most widely used cutting form in laser cutting technology. The laser power density used in this cutting technology is high. Once the laser is irradiated on the mechanical workpiece, except for a few Part of it will be reflected, and most of it […]

Analysis on the application of laser in modern manufacturing technology

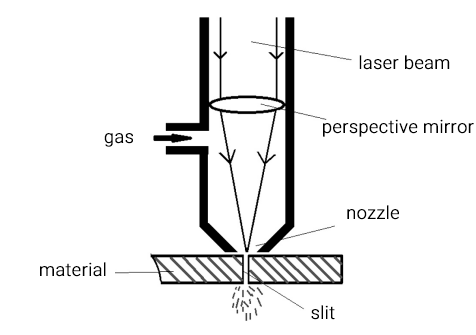

The essence of laser cutting technology is to form a laser beam by focusing high energy to directly melt or vaporize the workpiece to be processed. At the same time, the melt or oxide is processed under the action of auxiliary gas to complete the entire cutting operation. Laser cutting technology is a very advanced […]

Stainless steel laser cutting process optimization and surface quality research

Most items made of stainless steel are anti-corrosive, and items made of stainless steel are also processable. Therefore, stainless steel can be used in different fields, such as the aerospace industry, the medical industry, and different types of mechanical instruments. Industry, stainless steel materials are also widely used in coal mine machinery and facilities, and […]

Research on the application of laser processing technology in agricultural machinery manufacturing

Application of laser cutting technology in agricultural machinery manufacturing Laser cutting technology applies a laser beam to the surface that needs to be processed for processing. At this time, a very high temperature will be formed on the surface to complete the processing. After the application of the laser beam, the oxidation reaction can be […]

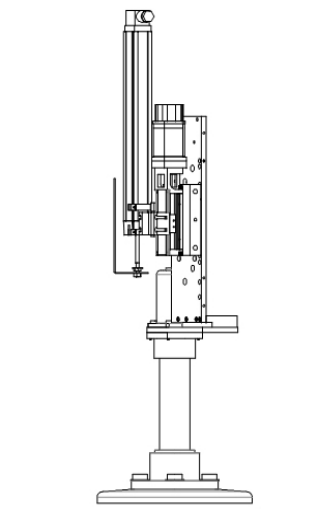

Laser cutting follow-up control system

The laser cutting servo control system is a mechanical device based on motion control and capacitive sensing, including four parts: controller, capacitance detection chip, capacitance sensor, servo motor, objective lens driving mechanism and input device. The working principle is to treat the laser nozzle and the metal cutting plate as a flat capacitor, and quickly […]

Application of laser processing technology in the manufacturing of transmission tower

Principles, characteristics and advantages of laser processing technology 1. 1 Principle of laser processing technology Laser processing is a very important high-energy beam processing method, which has the characteristics of strong laser directionality, high brightness, good monochromaticity, and good coherence. The principle of laser processing technology is that the laser light emitted by the laser […]

Research status and application of laser processing technology in marine engineering

Application of laser cutting technology in marine engineering There is a huge demand for metal cutting in the field of marine engineering. The traditional metal cutting technologies are high-speed oxygen-flame cutting technology and plasma arc cutting technology. However, both of them have shortcomings such as slow cutting speed, large thermal deformation of the workpiece, and […]