With the rapid development of the aerospace industry, higher requirements have been placed on the processing technology of aerospace engine parts. Traditional mechanical cutting has been unable to meet the needs for processing accuracy and processing efficiency. As a non-contact processing technology, laser processing has the advantages of high processing precision, small heat-affected zone, high processing efficiency, and high degree of automation. It shows great application prospects in the precision processing of key components of aerospace engines. Laser processing technology can achieve precision processing of complex three-dimensional structures that are difficult to achieve with traditional mechanical processing, greatly improving the overall performance of aircraft engine components.

Application of laser technology in aviation machining

Laser cutting technology

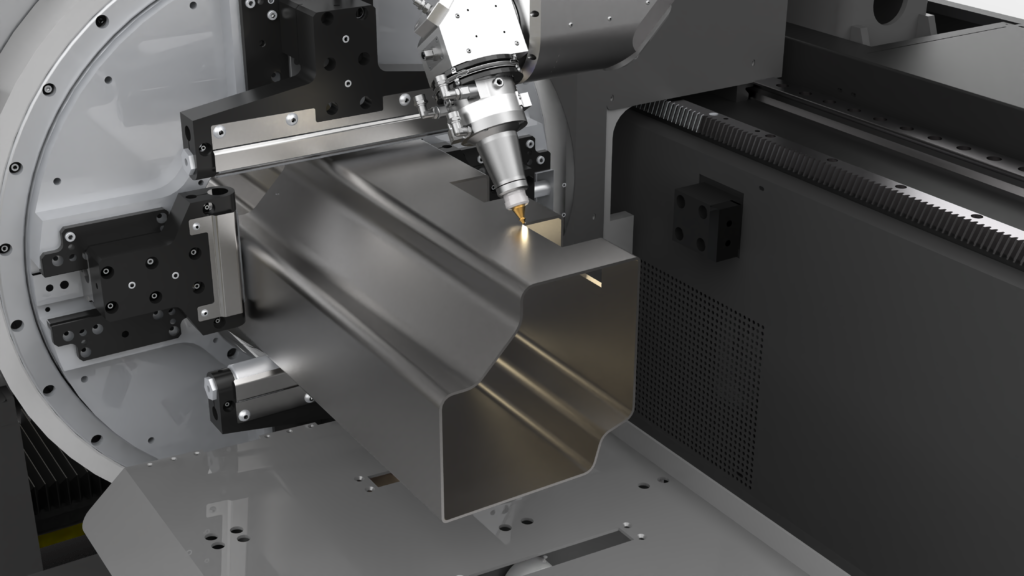

Laser cutting technology uses high-power density laser beam to irradiate the surface of the material to rapidly heat up local areas of the material. When the temperature rises to the melting or vaporization temperature of the material, the material will It begins to melt or vaporize and disintegrate, thereby realizing the cutting and processing of the material. The laser cutting system mainly consists of a laser, a CNC system, and a cutting head. Among them, lasers are the power source for cutting, and common ones include CO2 lasers, fiber lasers, etc.; the function of the CNC system is to control the laser. Laser Technology, as a new type of processing technology, has been widely used in high-end manufacturing fields such as aerospace and aerospace. This article takes the application of laser technology in aerospace machining as an entry point, analyzes the working principles, characteristics and specific applications of laser cutting, welding, drilling and surface treatment technologies, and proposes heat-affected zone control, deformation control, process Parameter optimization and other countermeasures to solve the challenges faced in the laser processing process are designed to conduct a comprehensive and systematic discussion of the application status and development trends of laser technology in the field of aerospace machining. Keywords: laser technology; aviation machining; laser welding. The output of the beam completes the preparation of the laser cutting trajectory; the cutting head is used to focus the laser on the object to be cut, so that the beam can accurately act on the material. Under the protection of inert gas, through appropriate selection of laser type, laser output power (CO2 laser power range 1 ~ 25kW, fiber laser power range 1 ~ 100kW), cutting speed (10 ~ 25m/min) and other processing parameters, laser cutting can Achieve material cutting. Compared with traditional mechanical cutting, the main advantages of laser cutting technology are:

| Laser working medium | YVO4 |

| Laser wavelength | 1064nm |

| Rated output power | 2000W |

| Beam quality | < 0.373mrad |

| Effective cutting range | 3000×1500mm |

| Axial positioning accuracy of worktable | ≤ ±0.0mm/m |

| Repeatable positioning accuracy of workbench | ≤ ±0.0mm |

| The maximum load capacity of the workbench is | 800kg |

| Power demand | 380V/50Hz/100A |

(1) High cutting quality. The incisions produced by laser cutting have smooth edges, narrow incisions, few burrs, and a processing accuracy of up to 0.05mm.

(2) The processing deformation is small. Laser cutting instantly generates high energy to locally melt and vaporize the material, avoiding the stress and vibration of mechanical cutting. Effectively control deformation.

(3) Cutting speed is fast. Laser cutting speeds can reach tens of meters per minute.

(4) Wide range of application. For example, laser cutting can cut complex curved surfaces in three-dimensional space, saving subsequent processing time. In the cutting of aero-engine turbine disks, compressor blades and other structural parts, compared with mechanical cutting, laser cutting technology also shows its unique advantages: high cutting accuracy, small heat-affected zone, small processing deformation, which can reduce subsequent processing difficulty and improve production efficiency. For example, in the cutting of titanium alloy compressor blades, a fiber laser cutting machine with an output power of 4kW and a cutting speed of 15m/min can obtain high-quality, smooth cuts with a heat-affected zone less than 0.3mm.

Laser welding technology

Laser welding technology refers to a technology that uses high-power laser beams to irradiate the joints of two parts to instantly melt or soften the material, and then solidify the connection to achieve welding.

Laser welding technology mainly has two working modes: heat conduction mode and deep penetration keyhole welding mode. Thermal conduction mode is suitable for laser welding with low power density, and the laser power density is between 104 and 105W/cm2. In this mode, laser irradiation causes a molten pool to form on the surface, and then the heat is conducted to the interior, causing the molten pool to expand to a certain depth. After the molten pool solidifies, the welding is completed. The welding speed of this mode is slower, and the general aspect ratio is about 1:4. The deep penetration keyhole welding mode uses high-power laser (power density greater than 105W/cm2) for welding. The laser quickly forms a deep steam hole on the surface of the material. The temperature of this hole can reach about 5000K, absorbing almost all the laser energy. The metal around the hole melts instantly, reaching a dynamic balance with the high-temperature and high-pressure metal vapor. As the laser irradiation point moves, the molten metal flows and fills behind the keyhole, completing the fusion. This kind of welding speed is very fast, which can reach several meters per minute, and the weld depth-to-width ratio can reach more than 10:1. Laser welding technology has been widely used in the field of aviation machining. First of all, in the manufacturing of aeroengine combustion chambers, laser welding successfully solved the welding problem of complex thin-walled structures. For example, when manufacturing single crystal high-temperature alloy combustion chambers, arc welding and electron beam welding will cause a lot of thermal stress and tissue damage. After using laser deep penetration welding technology, single-pass welding without filler was successfully achieved, and the weld depth and width were When the ratio is greater than 10, residual stress and deformation are significantly reduced. In addition, laser welding is also used to weld high-temperature thin-walled parts such as fuel nozzles and combustion chamber casings, solving the problems of poor welding quality and large deformation caused by traditional methods. For example, aerospace rocket engine combustion chambers place more emphasis on welding quality. Laser welding can achieve deep penetration keyhole mode, making the penetration depth reach more than 1/3 of the material thickness, ensuring the life of the combustion chamber. At the same time, the choice of continuous and pulsed dual-mode laser can flexibly cope with the welding requirements of different material thicknesses . In addition, large precision parts such as movable airfoils and casings in flight control systems are increasingly being welded by laser, which can reduce deformation, ensure geometric tolerances, and achieve lightweight design; combination welding of some special materials, For example, only laser welding can achieve the mixed welding of titanium alloy and stainless steel; key rotating parts such as aero-engine turbine blades, compressor blades, and bearing rings need to use laser welding technology to repair local damage, which can greatly extend the use of the parts. life and reduce replacement costs; the assembly of aero-engine tail nozzles is increasingly using robotic laser welding, which improves production efficiency.

Laser drilling technology

Compared with traditional mechanical drilling, laser drilling technology has the advantages of high drilling quality and fast processing speed, and has been widely used in the drilling processing of aerospace engine parts. During the laser drilling process, the laser pulses or continuous laser beams generated by the laser are first collected and focused by the focusing optical system. The beam is focused onto the metal surface to a focal spot with a diameter of up to tens of microns. This small area heats up rapidly due to the high light intensity, and the temperature can rise to the boiling point of the metal or higher within microseconds. When the temperature reaches the boiling point, explosive vaporization occurs on the metal surface, forming a high-speed jet of metal vapor in the opposite direction. The vaporized area continues to expand, eventually forming a hole through the material. At the same time, the temperature of the metal matrix surrounding the perforated area will not increase significantly due to the low laser energy density, and the heat-affected zone is very small. Key components such as aeroengine turbine disks and compressor blades require a large number of small holes on the surface to achieve cooling. These small holes have a diameter of 0.5 to 2 mm and are densely distributed, with the number reaching tens of thousands. For this type of small hole drilling, laser drilling technology can complete the drilling process in a few seconds, and the efficiency is much higher than traditional mechanical drilling. At the same time, the heat-affected zone produced by laser drilling is very small, the aperture error is controlled within ±0.1mm, and the inner surface quality of the hole is good, basically requiring no subsequent processing. Using laser drilling technology, the processing cost of aero-engine parts can be reduced by more than 60%. At present, femtosecond and picosecond narrow pulse lasers have become the mainstream technology for drilling aerospace engine parts. This type of ultra-short pulse laser has extremely short duration and ultra-high peak power, enabling “cold processing”. When drilling, the ultra-short pulse laser can instantly heat the metal surface to the boiling point to produce a micro-explosion, hollowing out the metal, without obvious heat-affected zones and thermal stress in the surrounding metal matrix, thereby ensuring the quality of the hole wall. Using a femtosecond laser with an average power of 1000W and a pulse width of 100fs, it is possible to drill holes with a diameter of 1mm and a depth of 20mm on the titanium alloy surface. The processing speed can reach 2000 holes/s, and the heat-affected zone is less than 20μm.

Laser surface treatment technology

Laser surface treatment technology is an advanced surface functionalization technology. It uses the thermal effect of laser to achieve rapid heating and cooling of surface micro-areas through precise heat treatment of the material surface, thereby obtaining excellent surface properties. This technology has the characteristics of small processing range, small deformation and high efficiency, and has important applications in the manufacturing of high-end equipment such as aero engines. Laser surface treatment can be divided into two main categories: surface modification and surface removal. Surface modification is to obtain ideal properties by controlling the surface microstructure with laser, and mainly includes processes such as laser remelting, laser alloying, laser coating and laser glazing.

(1) Laser remelting uses a high-density laser of about 100kW/cm2 to quickly scan the molten metal surface (cooling rate can reach 109°C/s), thereby obtaining a fine and uniform surface microstructure. This significantly improves the metal’s resistance to wear and fatigue.

(2) Laser alloying introduces new alloy elements through pre-preparing alloy materials, electroplating layers on the surface while laser melting, and changes the surface chemical composition. The general laser power density is 103 ~ 104kW/cm2. Unlike remelting, alloying creates composite layers with special properties.

(3) The principle of laser coating is similar, but it focuses more on controlling the amount and depth of externally added materials to accurately control the composition and properties of the surface layer.

(4) Laser glazing refers to the use of lower laser density to form a melted layer of only a few microns, which is quickly quenched to generate an amorphous surface, thereby obtaining excellent corrosion resistance. Surface removal treatment mainly refers to laser cleaning, which can remove surface contaminants and coatings efficiently and pollution-free. Compared with traditional mechanical or chemical cleaning, laser cleaning has the advantages of no solvent, no contact, and no secondary pollution. The general cleaning mechanism is to quickly heat up the surface material and vaporize it, or react with a preset liquid or gas to generate a shock wave, thereby lifting the contaminants off the surface. At present, laser surface treatment has been widely used. For example: laser honing on the surface of the engine cylinder can form oil storage microcavities, which greatly improves lubrication performance; laser remelting on aeroengine turbine blades can enhance their resistance to high-temperature oxidation and fatigue; on key bearings Laser alloying improves load-bearing capacity; stainless steel significantly improves corrosion resistance after laser glazing.

Challenges and Countermeasures

Heat Affected Zone Control

During the laser processing of aerospace machinery components, due to the highly concentrated state of the laser itself, the temperature of the processing area rises extremely quickly, resulting in an obvious heat-affected zone, which will lead to a reduction in the mechanical properties of the material, and in severe cases, the formation of a matrix. Defects such as phase transformation, residual stress and thermal cracks. Aviation aluminum alloy materials Al-Cu-Li-Mg-Ag series have been widely used in the aerospace field due to their low density, high strength, high elastic modulus, and good fatigue resistance. However, its thermal physical properties are poor and its thermal conductivity is low, making it easier to produce heat-affected zones during laser processing. For example, when laser welding 2060 aluminum alloy, the hardness of the weld zone can reach 240HV, which is much higher than the 167HV of the base material. This is mainly caused by the precipitation of a large number of fine tip-like phases along the weld area and the refinement of the structure. At the same time, the residual stress can reach 300MPa, which will have an adverse effect on the fatigue strength. In order to control the heat affected zone, optimization of process parameters and improvement of material design can be carried out. Process parameter optimization methods include: using continuous lasers, reducing laser power density, controlling heat input per unit time, and reducing molten pool size; optimizing scanning speed, using faster speeds to shorten heat input time while ensuring processing quality; optimizing focus Spot size, expand the spot area to disperse the input heat. Material design methods include: optimizing alloy elements to reduce differences in thermal properties; micro-alloying design to use trace elements to suppress phase changes; and adopting sandwich preset design to improve thermal stability.

Material deformation control

Most metal materials used in aviation manufacturing have high reflectivity, which requires laser processing to use high-power-density laser beams for processing. High-power-density laser irradiation can easily cause the material to overheat, causing significant thermal stress and Thermal deformation. If it cannot be effectively controlled, the thermal stress deformation of the material will directly affect the processing quality and accuracy. For example, when laser cutting an aluminum alloy material with a thickness of 2mm, if a CO2 laser cutting with a power of 1000W and a speed of 5000mm/min is selected, the theoretically calculated energy density of the laser input per unit length is approximately 100J/mm. However, considering that the energy conversion efficiency of the laser is about 20%, the actual absorbed laser energy is 20J/mm. Therefore, with the continuous irradiation of the laser beam, the metal surface temperature rises rapidly and is greater than the melting point temperature of the aluminum alloy after 633°C. , the aluminum alloy material begins to melt. However, the temperature of the metal around the melting zone is still 100 to 500°C, which will produce large temperature differences and thermal stress inside and on the metal [5]. Studies have shown that under these process parameters, the thermal deformation of 2mm thick aluminum alloy material can reach 0.2mm, which is difficult to meet the processing quality requirements of aerospace products. In order to control the thermal deformation of materials, comprehensive control is required from multiple aspects. Specific measures include: rationally configuring power and scanning speed, controlling laser energy density input, and avoiding excessive heat accumulation; optimizing scanning strategies and using scanning modes such as staggered scanning. , to avoid local overheating; select appropriate auxiliary gas and increase gas flow to help dissipate heat; use fixtures or fixtures to limit thermal deformation of the material; optimize the laser path to avoid heat accumulation areas; preprocess the material to change the response of the material characteristics, inhibit deformation, etc.

Schlussfolgerung

Modern laser technology is widely used in the field of aerospace machining, which greatly improves processing quality and efficiency, reduces costs, and broadens the scope of processing. The application of laser technology provides strong support for the development of the aviation manufacturing industry. At present, laser processing technology is developing towards intelligence, refinement, and multi-function, and has broad application prospects in the future. Relevant enterprises and scientific research institutes should speed up the innovative research and development of laser technology and equipment, continuously optimize laser processing technology, and achieve independent controllability of laser processing equipment to ensure the sustainable development of the aviation equipment manufacturing industry.