The use of laser cutting technology has become increasingly commonplace in many manufacturing and industrial processes, largely due to its ability to provide a precise, clean cut. One such process is tube laser cutting machines, which are able to cut round and square tubes with speed, accuracy and reliability. In this article, we will explore the fundamentals of how a tube laser cutting machine works and why it is so effective at producing parts with high precision.

What is a Tube Laser Cutting Machine?

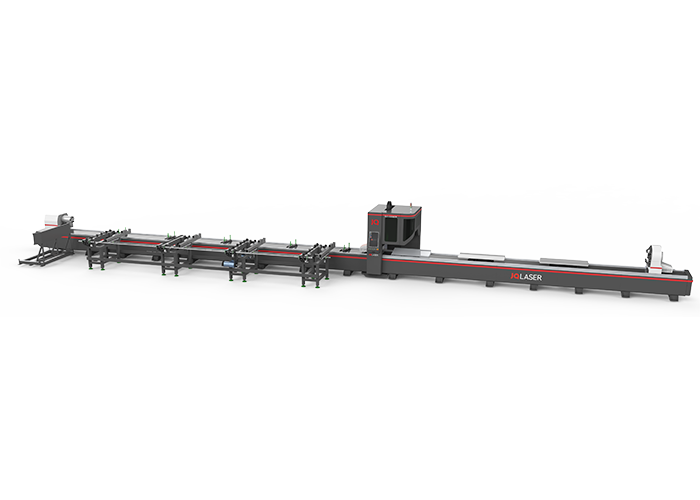

A tube laser cutting machine is a type of laser cutting device which uses intense heat to cut through metal tubes and pipes. It is an important tool in the modern industrial manufacturing sector, as it offers higher precision and faster production times than traditional methods. By accurately controlling the diameter, length, and shape of each tube or pipe that passes through the machine, manufacturers can produce products with greater accuracy and efficiency.

The tube laser cutting machine works by focusing a beam of high-energy light on the material that needs to be cut. This focused beam quickly heats up the material until it melts or vaporizes, allowing for intricate designs with minimal loss of materials. The laser also has great accuracy when creating multiple cuts within tight tolerances – something not possible with traditional methods such as mechanical saws or hand torches.

Working principle

As its name implies, this type of machine uses lasers to cut through material with accuracy and speed. But how does the tube laser cutting machine work? This article will explain the working principle behind this amazing technology. At its core, the tube laser cutting machine works by focusing a beam of powerful light onto a metal surface in order to carve away at it. The operator first inputs instructions into the control system that dictates where and how deep to cut. Once activated, an array of mirrors direct the laser beam onto the target object, which is then vaporized as it melts away from heat generated by the intense light source.

Parts of the Machine

The machine is comprised of several components, all essential to ensure smooth operation. Understanding the individual parts and how they function together is key in providing an efficient and reliable cut. The main component of the tube laser cutting machine is the optical system which includes both the laser source, and fiber delivery system. This system works by focusing a beam of light on a specific spot so that it can be used to cut materials accurately and quickly without damaging them. Other important components include sensors, drives, control systems, cooling systems and dust extraction units which help regulate temperature and keep fumes away from operators as well as improve air quality during cutting operations.

Process of Laser Cutting

Process of Laser Cutting is a complex and precise process that provides countless benefits to the manufacturing industry. A tube laser cutting machine uses highly advanced technology to produce an accurate cut without causing any damage to the material, resulting in smoother edges and less waste. The process begins with a computer-aided design (CAD) software program creating a digital file of the desired product shape or design. This digital file is then sent to the laser cutting machine where it is used as a guide for where and how deep the laser will cut into the material. During this stage, precision optics inside the tube laser cutter adjusts its angle and focus so that it can accurately follow each detail of the design.

Applications

Tube laser cutting is a highly precise process used by industrial manufacturers to create components for a wide range of applications. Laser tube cutting machines are computer-controlled and use lasers to cut parts from metal, plastic, or other materials with incredible accuracy and speed. The machine works by focusing a high-powered laser beam on the material which then melts, burns, or vaporizes it away in order to shape the desired part.

This versatile technology can be used on any type of tube or pipe to produce complex shapes with very tight tolerances. It’s most commonly used in automotive and construction industries due to its ability to accurately fabricate metal tubes into intricate parts that would otherwise require much more time consuming traditional methods like manual welding or plasma cutting. Tube laser cutting technology is also used in aerospace engineering where extremely precise cuts need to be made quickly with minimal waste.

Potential Issues

In order for a tube laser cutting machine to work properly, several moving parts must be kept in alignment and adjusted correctly. If any part of the system becomes misaligned or out of calibration, there can be serious implications on the quality of the cut product and potentially even safety hazards due to mechanical failure. Additionally, software updates or upgrades may also be necessary over time as new technologies are developed which could result in additional costs or downtime during installation.

It is essential for those considering investing in this technology understand these potential issues and make sure they have both the technical expertise and resources available should problems arise.

Maintenance Tips

Maintaining any industrial machine is an important part of the production process. Tube laser cutting machines are no exception. To ensure these machines run smoothly, regular maintenance is key. In this article, we’ll explore how a tube laser cutting machine works and provide some helpful tips to keep your machine running optimally. Tube laser cutting machines use a gas-assisted beam of light to cut and shape tubes made from materials like steel, aluminum, brass and copper. The machine itself consists of several components including the main chassis and frame, a set of optics for controlling the beam path, a water cooling system for cooling the components during operation as well as motion control systems for adjusting the speed and accuracy of cuts being made.

Schlussfolgerung

The conclusion of this article on how a tube laser cutting machine works is simple – it is an effective and efficient way to cut metal tubes into the desired shape with minimal waste. This method of laser tube cutting has been used in many industries, from automotive to aerospace and beyond. Not only does it produce consistent results, but it also requires very little setup time and can be completed quickly, making it ideal for large scale production runs.

Thanks to advances in automation technology, modern tube laser cutting machines are equipped with advanced programming capabilities that allow for improved accuracy and precision when creating complex shapes. Furthermore, these machines are designed to use less energy than other conventional methods of cutting metal tubes while maintaining superior quality results – making them the preferred choice among manufacturers looking for cost-effective solutions.