Introduction

Choosing the right laser cutting system is essential for achieving maximum productivity and accuracy. Laser cutting systems have become an increasingly popular tool for cutting and forming a variety of materials. Not only is it quick and efficient, but it’s also incredibly precise and accurate. Before you invest in a laser cutting system, it’s important to consider a few key factors to ensure you choose the right system for your needs. This guide will provide an overview of the different types of laser cutting systems, important considerations for choosing the right system, and how to maximize productivity and accuracy.

Evaluating Your Needs: What Power and Speed Should Your Laser Cutting System Have?

When evaluating the needs of a laser cutting system, it is important to consider the power and speed requirements. The power of the laser cutting system is determined by the type of material that needs to be cut, as well as the thickness of the material. The power rating should be selected based on the type of material and the thickness of the material that will be cut. In addition, the speed of the laser cutting system should also be taken into consideration. The speed of the laser cutting system should be selected based on the size of the material being cut, as well as the complexity of the cutting process.

It is important to select a power and speed setting that will provide the optimum performance for the material being cut. As a general rule, higher power and faster speeds are required for thicker materials, while lower power and slower speeds are typically best for thinner materials. Additionally, the complexity of the cutting process may also require different power and speed settings. For example, complex shapes and intricate designs may require higher power and speed settings, while simpler shapes may require lower power and speed settings.

How to Make the Most Out of Your Laser Cutting System

Using a laser cutting system can be an incredibly efficient and precise way to complete projects, but it does take some practice and skill to master. Here are some tips for getting the most out of your laser cutting system:

- Make sure your workspace is well organized. Your laser cutter will only produce accurate cuts if it is stable and level. Clear away any clutter or obstacles that could interfere with your machine’s movement.

- Choose the right materials. Different materials have different properties, and require different settings for optimal cutting. Research the materials you plan to use and find out what settings work best.

- Experiment with settings. Once you’ve decided on the material and settings you want to use, it’s important to test them out before starting a project. Make a few test cuts on a scrap piece of material to make sure the settings are correct.

- Maintain your laser cutter. Clean and lubricate the machine regularly according to the manufacturer’s instructions. This will help ensure that it is working at its best.

- Practice. You can get better results with your laser cutting system by practicing often. Try different speeds and settings to get a feel for how your machine works and what it can do.

By following these tips, you can make the most out of your laser cutting system and create precise and accurate cuts. With a bit of practice, you will be able to get the most out of your machine and produce professional-looking results.

How to Select the Right Laser Cutting System for Your Business

As it can have a significant impact on the success of your operations. Laser cutting systems are used in a variety of industries, and they can be used to cut a wide range of materials, including metals, plastics, wood, and composites.

When selecting the right laser cutting system for your business, there are several important factors to consider.

Material Types and Thickness

The first step in selecting the right laser cutting system is to determine the types of materials you will be working with and their thickness. Some systems are optimized for specific materials, while others offer greater flexibility to handle various materials.

Laser Power and Wattage

The laser power and wattage significantly influence the cutting speed and efficiency of the system. Higher wattage lasers generally provide faster cutting speeds, which can enhance productivity, especially when dealing with thick materials.

Cutting Speed and Productivity

Productivity is a critical factor in any manufacturing process. Choosing a laser cutting system with higher cutting speeds can result in faster turnaround times and increased production capacity.

Accuracy and Precision

Precision is paramount in laser cutting applications. The accuracy of the system will determine the quality of the final product. Look for a laser cutting machine that offers high precision to avoid costly errors and rework.

Automation and Software Compatibility

Automation features and software compatibility can streamline your workflow and improve efficiency. Some laser cutting systems come with advanced automation options that reduce manual intervention, leading to higher productivity.

Comparing the Pros and Cons of Fiber Laser and CO2 Laser Cutting Systems

Fiber laser and CO2 laser cutting systems are two of the most popular methods for cutting material in industrial settings. Both offer a range of advantages, but there are distinct differences between the two that should be considered when selecting a system. This article will compare the pros and cons of fiber laser and CO2 laser cutting systems to help you make an informed decision.

Fiber Laser Cutting Systems

Fiber laser cutting systems utilize an infrared beam to cut material, as opposed to the UV beam used in CO2 laser systems. The major advantage of fiber laser cutting systems is that they are more efficient and require less energy than traditional CO2 laser systems. The infrared beam is created when the laser beam is amplified by a doped fiber medium, which has a higher energy efficiency than other methods. Fiber laser cutting systems are also more precise and can cut thicker material than CO2 laser systems.

On the downside, fiber laser systems cost more than CO2 laser systems, both in terms of initial purchase price and long-term maintenance costs. Additionally, they require more time to set up and operate, making them less suitable for rapid or frequent cutting jobs.

CO2 Laser Cutting Systems

CO2 laser cutting systems use UV beams to cut material and are the most commonly used type of laser cutter. The major advantages of CO2 laser systems are their affordability and the fact that they can be used for a wide range of materials. They are also faster and easier to set up and operate than fiber laser systems, making them ideal for rapid cutting jobs.

However, CO2 laser systems are not as precise as fiber laser systems and require more energy to operate. Additionally, they are not as efficient as fiber laser systems, meaning that more energy is wasted in the cutting process. They also cannot cut through thicker materials as efficiently as fiber laser systems.

The Benefits of Automated Laser Cutting Systems

Automated laser cutting systems offer a range of benefits to manufacturers. These systems provide a reliable, efficient method of cutting a variety of materials with precision and accuracy. Automated laser cutting systems offer higher levels of productivity, improved quality of work, and cost savings.

Automated laser cutting systems are capable of working at high speeds, providing quick, accurate results. The laser beam is capable of cutting complex shapes with great precision and accuracy, and can be programmed to accurately cut any number of shapes. This high level of precision and accuracy provides a higher quality of work than manual cutting methods.

The use of automated laser cutting systems also results in increased productivity. The high speed of the laser beam allows for faster production times, resulting in higher throughputs. As the laser beam is programmed to cut a variety of shapes accurately, it also eliminates the need for multiple manual cutting operations, resulting in fewer errors.

Automated laser cutting systems also provide cost savings. The laser beam is capable of cutting materials with minimal waste, resulting in significant cost savings. The high speed of the laser beam also results in shorter production times, resulting in increased output and cost savings.

Overall, automated laser cutting systems offer a range of benefits to manufacturers. They provide greater precision, accuracy, and productivity, resulting in higher quality work and cost savings. This makes them an ideal choice for manufacturers looking for a reliable, efficient way to cut materials.

What to Look for in a Laser Cutting System to Ensure Maximum Productivity and Accuracy

When selecting a laser cutting system, it is important to ensure that the system is capable of delivering maximum productivity and accuracy. To ensure the best performance of the system, the following key features should be taken into consideration:

- Laser Source: The laser source should be powerful enough to efficiently and quickly cut through the material being processed. High-power CO2 lasers are typically preferred as they offer a fast cutting speed and excellent accuracy.

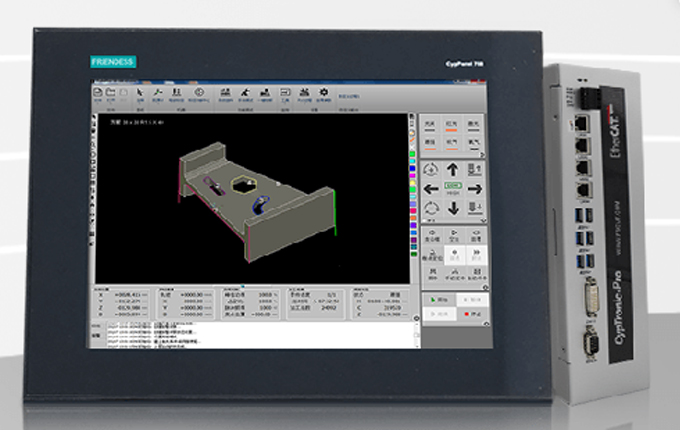

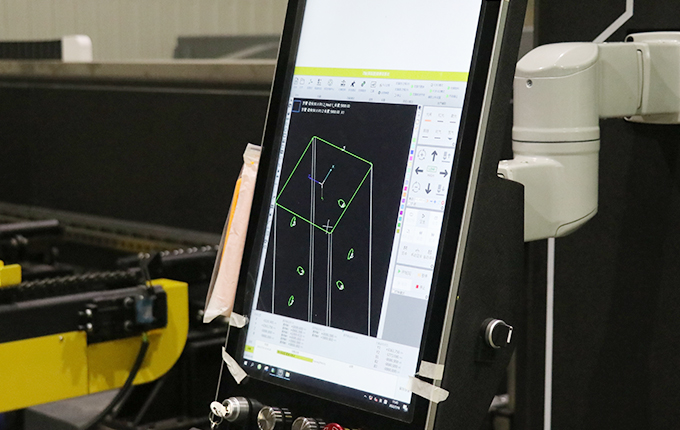

- CNC Control System: A good CNC control system should be able to accurately control the laser cutting process, with the ability to control the laser’s movements, power, and speed. A good CNC control system should also be easy to use and program, allowing for quick setup and programming of the cutting process.

- Beam Delivery System: The beam delivery system should be capable of accurately delivering the laser beam to the cutting point, with minimal reflection and distortion. The beam delivery system should also be robust and reliable, ensuring that the laser beam remains accurate and stable throughout the cutting process.

- Automation: Automation is essential for maximizing efficiency and productivity. Automation features should include automatic material feeding and unloading, automatic nozzle cleaning, and automatic material positioning.

- Safety Features: Laser cutting systems should be equipped with safety features to protect both the operator and the system itself. This includes a safety enclosure to protect against laser radiation, as well as safety features such as interlocks, motion sensors, and emergency stops.

Exploring the Different Types of Laser Cutting Systems and Their Uses

The type of laser cutting system required for a particular job will depend on the material and the desired result. There are three main types of laser cutting systems: CO2 laser cutting, fiber laser cutting, and excimer laser cutting.

CO2 laser cutting systems are the most widely used type of laser cutting system. They use a beam of infrared light to cut, engrave, and mark materials such as plastics, wood, and leather. CO2 laser cutting systems are ideal for cutting intricate designs and shapes.

Fiber laser cutting systems use a beam of light from a fiber laser source to cut, engrave, and mark metals such as steel and aluminum. They are ideal for cutting thick materials and for producing higher quality finishes.

Excimer laser cutting systems use a beam of ultraviolet light to cut and engrave materials. They are typically used to produce intricate shapes and markings on glass and other hard materials.

Laser cutting systems are used in a variety of industries including automotive, medical, aerospace, and electronics. They are used to produce parts and components, such as gears and sheet metal parts, for a variety of applications. In addition, laser cutting systems are used to create signs and displays, engrave jewelry, and personalize products.

Laser cutting systems are highly precise and efficient tools that can be used to produce a variety of products with accuracy and detail. With the right laser cutting system, any job can be completed quickly and accurately.

Schlussfolgerung

The right laser cutting system can have a huge impact on the productivity and accuracy of any manufacturing operation. Taking the time to research, compare, and ultimately choose the right system can help to ensure that the system is up to the job and will operate efficiently and accurately. With the right system in place, manufacturers can rest assured that they have the right tool for the job, and that their products will be of the highest quality.