Introduction

Tube laser cutting is an advanced technology that has revolutionized the way materials are cut. It offers a variety of benefits, including faster and more accurate cutting. If you are new to tube laser cutting or want to brush up on the basics, this guide will help you get started. We’ll provide tips and tricks to help you better use a tube laser cutter and get the most out of your cutting projects. Learn how to properly set up your machine and use the right settings for each job, as well as how to maintain your laser cutter for optimal performance. With the right knowledge and practice, you’ll be able to use a tube laser cutter like a pro!

Utilizing Advanced Features of Tube Laser Cutters for Maximum Productivity

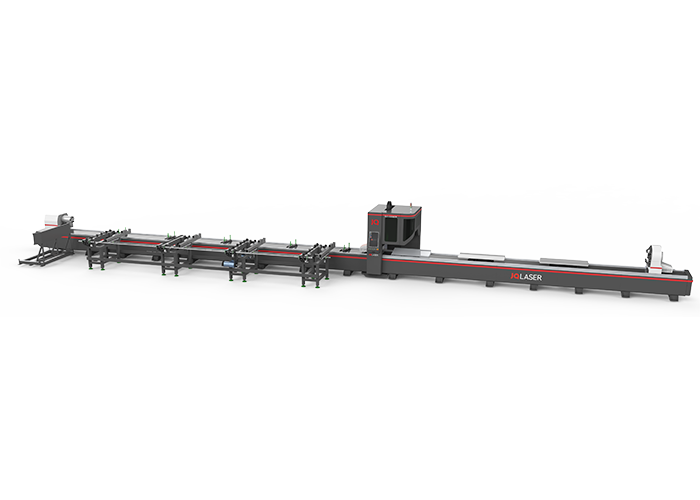

Tube laser cutters are a type of machine tool that can be used for a variety of applications. They offer high levels of accuracy and productivity, making them ideal for cutting shapes into metal tubes, pipes, and profiles. To maximize productivity, it is important to understand and utilize the advanced features of tube laser cutters.

One of the most important features of tube laser cutters is their ability to adjust the speed and power of the laser beam. This feature allows the user to fine-tune the cut to reduce cycle time and maintain high levels of accuracy. In addition, this feature can also be used to reduce heat-affected zones around the cut, which can help to prevent warping and distortion.

Another important feature is the ability to change the focal length of the laser beam. This is especially important for cutting longer tubes, as the focal length can be adjusted to ensure a precise cut along the entire length of the tube. This feature can also be used to minimize burrs and keep the cut surface smooth.

Tube laser cutters also feature additional cutting modes, such as “pulsed” or “scored” cutting. Pulsed cutting is ideal for thicker materials, as it reduces the amount of heat generated during the cut. Scored cutting, on the other hand, is ideal for thinner materials, as it minimizes the amount of material that needs to be removed.

Finally, tube laser cutters can be equipped with advanced automation systems, such as robotic loaders and unloaders. This type of automation helps to reduce labor costs and increase throughput. It also allows for multiple tubes to be cut at once, which can further increase productivity.

In conclusion, tube laser cutters are powerful and versatile tools that can be used for a variety of applications. By understanding and utilizing the advanced features of these machines, users can maximize productivity and maintain high levels of accuracy.

Maintaining Your Tube Laser Cutter for Long-Term Use

Maintaining a tube laser cutter is essential for keeping it running in top condition and maximizing its lifespan. With proper upkeep and maintenance, you can ensure that your machine will continue to provide reliable and accurate cutting and fabrication services for many years.

To keep your tube laser cutter in optimal condition, follow these best practices:

- Clean and inspect your machine regularly. Regularly wiping down the machine and its components can help to prevent dirt and dust from accumulating and potentially causing damage. Additionally, routinely inspecting the machine for signs of wear and tear or malfunction can help to identify any issues before they become serious problems.

- Keep the machine well lubricated. Lubricating the machine regularly helps to ensure that it is running smoothly and efficiently. Make sure to use the right lubricant for your machine and follow the manufacturer’s instructions for application.

- Store the machine properly. Make sure to store the machine in a clean and dry area away from direct sunlight and other sources of heat. Additionally, if the machine has a cover, make sure to keep it on when not in use to keep dust and other particles from entering the system.

- Perform regular maintenance. Depending on the type and frequency of use, regular maintenance may be required. This can include replacing worn or broken parts, calibrating the machine, and running diagnostic tests to ensure that it is performing optimally.

By following these tips, you can ensure that your tube laser cutter will remain in top condition for many years to come. With proper care and maintenance, your machine will be able to provide accurate and reliable cutting and fabrication services for a long time.

Troubleshooting Common Problems with Tube Laser Cutters

Tube laser cutters are versatile and efficient tools that can streamline the production of complex parts. However, like any other machine, they can sometimes run into problems. In this article, we will discuss some of the most common issues experienced with tube laser cutters and how to troubleshoot them.

One of the most common problems experienced with tube laser cutters is poor cutting performance. This can be caused by a variety of issues, such as incorrect settings, worn or broken parts, or a worn laser source. To troubleshoot this issue, start by checking the settings on the machine, as well as the condition of the laser source and any other components. If everything appears to be in working order, then the issue may be with the material itself, such as a mismatched thickness or contamination.

Another common issue with tube laser cutters is an inaccurate cut. This can be caused by incorrect settings, a worn lens, or a misaligned nozzle. To troubleshoot this issue, start by checking the settings on the machine, as well as the condition of the lens and the nozzle. If everything appears to be in working order, then the issue may be with the material itself. In this case, check for inconsistencies in the material’s thickness or contamination.

Finally, tube laser cutters can sometimes experience issues with their power supply. This can be caused by a variety of issues, such as an overloaded circuit or a faulty power source. To troubleshoot this issue, start by checking the power source and any related components. If everything appears to be in working order, then the issue may be with the machine itself, such as a faulty power circuit or a worn power supply.

By following the steps outlined above, you should be able to troubleshoot any common issues experienced with tube laser cutters. However, if you are still unable to resolve the issue, then it may be best to contact a professional for assistance.

Setting Up the Tube Laser Cutter for Maximum Performance

First, it is important to inspect the machine for any potential safety hazards. This includes checking the wiring, checking for any loose parts, and making sure the machine is securely fastened to the floor. Once the machine has been inspected and approved, it is important to ensure that all components of the machine are in proper working order. This includes cleaning and lubricating the machine, checking the nozzles, and making sure the lenses and mirrors are properly aligned.

Once the machine is ready for use, it is time to prepare the material for the laser cutting process. This includes selecting the correct type of material and the proper size for the job. Before beginning the process, the material should be secured on the bed of the machine to prevent it from shifting during the cutting process. It is also important to adjust the settings on the machine to ensure the optimal cutting power and speed for the material being used.

Finally, it is important to familiarize yourself with the safety protocols that come with operating a tube laser cutter. This includes wearing eye protection at all times while operating the machine, avoiding contact with the beam, and turning off the machine before leaving the area. Following these protocols can help to ensure that the machine is operated safely and efficiently.

Safety Measures Before Operation

Safety should always be a top priority when using any machinery, including a tube laser cutter. Before commencing operation, ensure the following safety measures are in place:

– Wearing Protective Gear

Operators should wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and protective clothing, to shield themselves from potential hazards.

– Proper Ventilation

Tube laser cutting can generate fumes and smoke, especially when cutting certain materials. Adequate ventilation is essential to maintain air quality in the working area and to prevent health risks.

– Machine Inspection

Regularly inspect the machine for any signs of damage or malfunction. Ensure that all safety features are functional and well-maintained.

Preparing Materials for Cutting

The quality of the cutting process heavily depends on the preparation of materials. Follow these steps to prepare your materials effectively:

– Material Selection

Choose the appropriate material for your project, considering factors like thickness, type, and compatibility with the tube laser cutter.

– Cleaning and Prepping

Clean the materials thoroughly to remove any dirt, oil, or debris that may interfere with the cutting process. Proper prepping ensures a clean and accurate cut.

– Securing the Material

Secure the material firmly in place to avoid any movement during cutting, which can lead to inaccuracies.

Tips for Optimizing Tube Laser Cutting for Efficiency and Accuracy

1. Utilize High-Quality Materials: The quality of the material being cut will directly affect the quality of the finished product. Utilizing high-quality materials that are properly aligned and held in place will ensure that the cuts are precise and efficient.

- Properly Align the Tube: Prior to cutting, ensure that the tube is properly aligned in the laser cutting machine. This will ensure that the cuts are accurate and that the finished product is of a high quality.

- Utilize the Proper Laser Settings: It is important to select the correct laser settings for the type of material being cut. Different materials require different settings in order to produce the best results.

- Choose the Right Focal Point: Choosing the right focal point for the laser is key for achieving accurate and precise cuts. The focal point should be adjusted to the correct distance from the material in order to ensure that the laser is focused properly.

- Utilize Automation: Automation can be a great tool for achieving faster and more precise cuts. Automation can be used to control the speed of the laser, the number of passes, and the focal point.

- Monitor the Cutting Process: Monitoring the laser cutting process is essential for ensuring that the cuts are accurate and that the product is of a high quality. Periodically check the progress of the cut to ensure that it is on track.

- Maintain the Laser: Regular maintenance of the laser is key for ensuring that the cutting process is efficient and accurate. Take the time to clean and calibrate the laser to ensure that it is working properly.

- Use the Appropriate Abrasives: Selecting the right abrasives is important for producing accurate and precise cuts. Using abrasives that are too coarse or too fine can result in inaccurate cuts and uneven edges.Selecting the Right Tube Laser Cutter for Your ProjectWhen it comes to cutting metal tubes and pipes, a tube laser cutter is an ideal machine for the job. However, with so many tube laser cutters available on the market, it can be difficult to know which one is best for your project. To help you make the right choice, here is a guide to selecting the right tube laser cutter for your project.

Understanding the Basics of Tube Laser Cutting and Its Benefits

Tube laser cutting is a popular and efficient method of cutting metal tubes and pipes. This method involves using a laser beam to cut through the material, resulting in precise and accurate cuts that are difficult to achieve through traditional cutting processes. It is a fast and cost-effective way to produce a wide range of products, and is widely used across many industries for its numerous benefits.

The key benefit of tube laser cutting is its precision. Lasers can produce parts with tight tolerances and complex shapes, which can be difficult to achieve through traditional cutting processes. Laser cut parts also have a higher level of accuracy, with no need for secondary operations. This can lead to improved quality, shorter lead times, and lower overall costs.

Another advantage of this process is the speed at which it can be completed. Laser cutting is much faster than traditional cutting methods, as the laser beam can cut through the material quickly and efficiently. This can lead to improved productivity, as fewer parts need to be cut to achieve the desired result.

Tube laser cutting also has environmental benefits. This process produces little to no hazardous waste, as the laser beam does not create a physical force on the material. This means that there is no need for coolants or lubricants, which reduces the risk of contamination. Additionally, the process generates very little noise and does not require much energy, making it a more sustainable option.

In addition, tube laser cutting offers flexibility. This process can be used to cut a wide range of materials, including metals, plastics, and composites. Additionally, it can be used to create complex shapes, such as curved or angled cuts. This makes it an ideal choice for prototyping and production runs.

Tube laser cutting is an effective and efficient way to cut metal tubes and pipes. It offers many benefits, such as increased precision, speed, and flexibility. Additionally, it is a more sustainable option that produces minimal waste and requires little energy. For these reasons, it is widely used across many industries.

Schlussfolgerung

In conclusion, using a tube laser cutter effectively requires careful consideration regarding the material, design, and settings used. Careful design and material selection can help optimize the cutting process and reduce the risk of defects. Additionally, it is important to understand the specific settings and parameters used to get the best possible results from the tube laser cutter. Taking the time to understand the machine and the cutting process can help ensure that the cutting process is efficient and accurate.