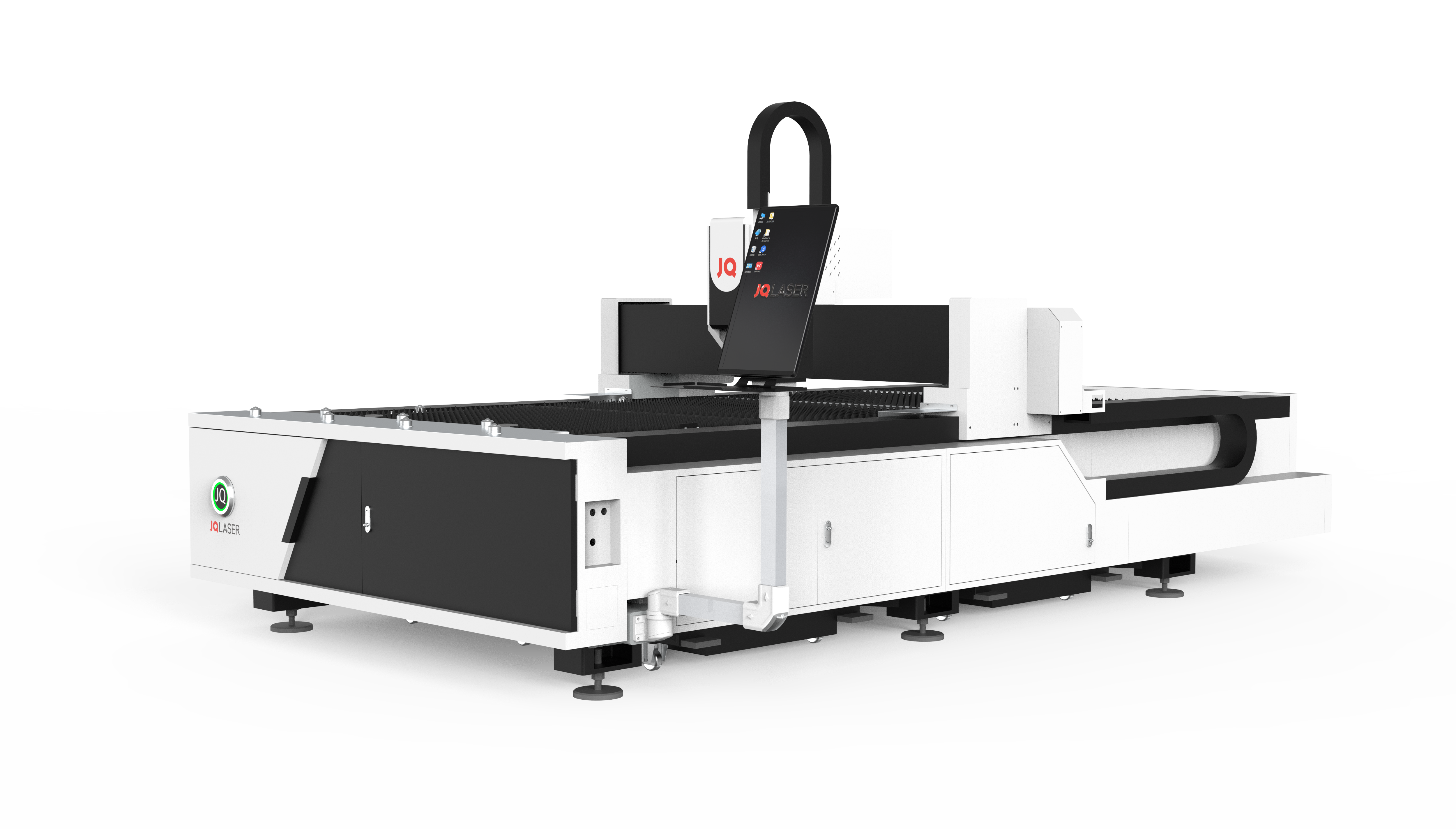

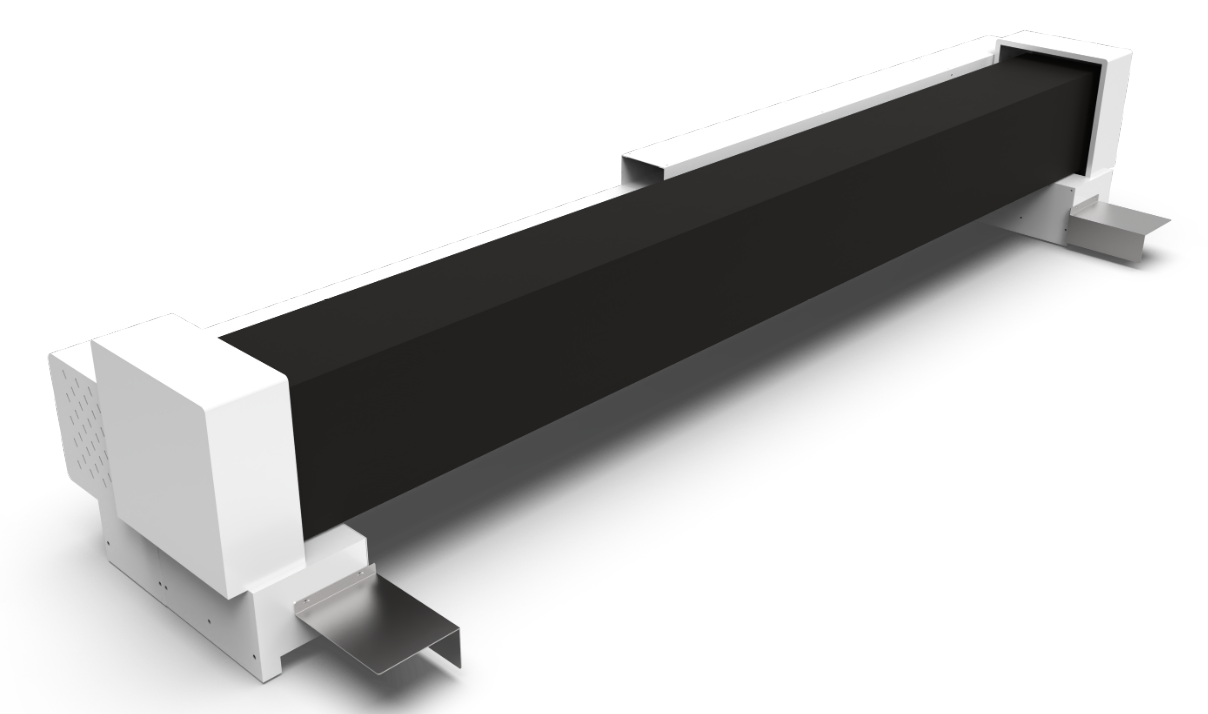

JQ-1530E v2.0

Start off on the right foot

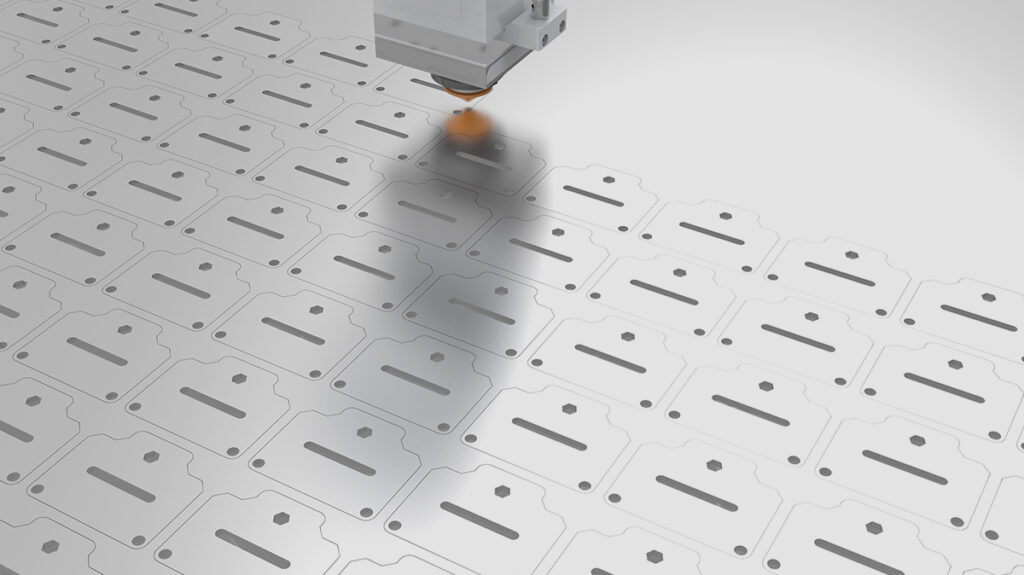

Plate cutting

Power available

3 – 12KW

Loading weight

1200KG

Arbeitsbereich: 3000*1500mm

Verfahrweg der X-Achse: 1550mm

Verfahrweg der Y-Achse: 3050mm

Verfahrweg der Z-Achse: 120 mm

The best of technology in the smallest member of the family

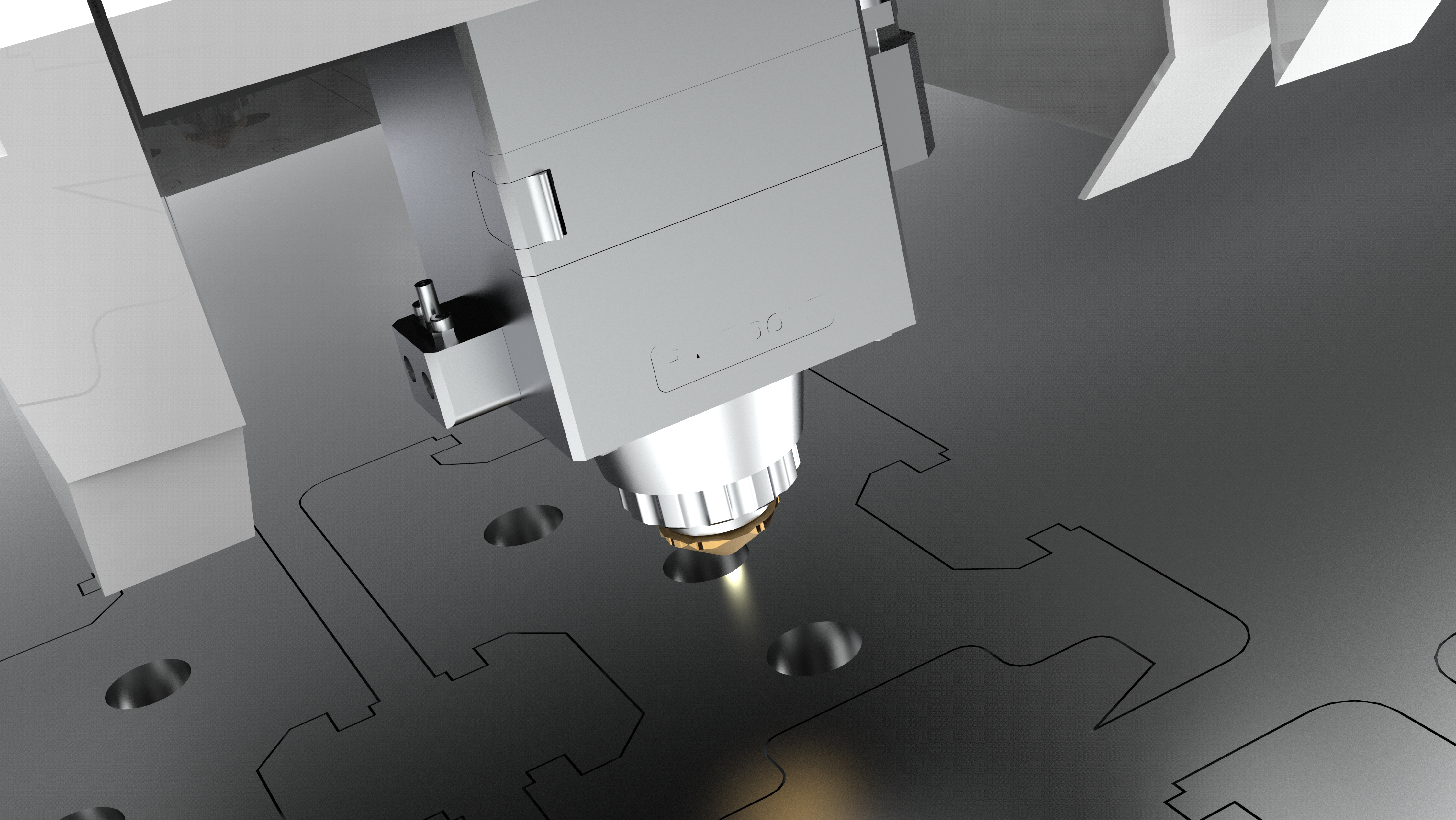

With the new Plate Cutter cutting head equipped on the JQ-1530E v2.0 , you will produce high quality parts. With automatic focus and integrated laser parameter management, there is no need for adjustments.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

Shipping solutions such as shipping in a container without removing sheet metal and beams

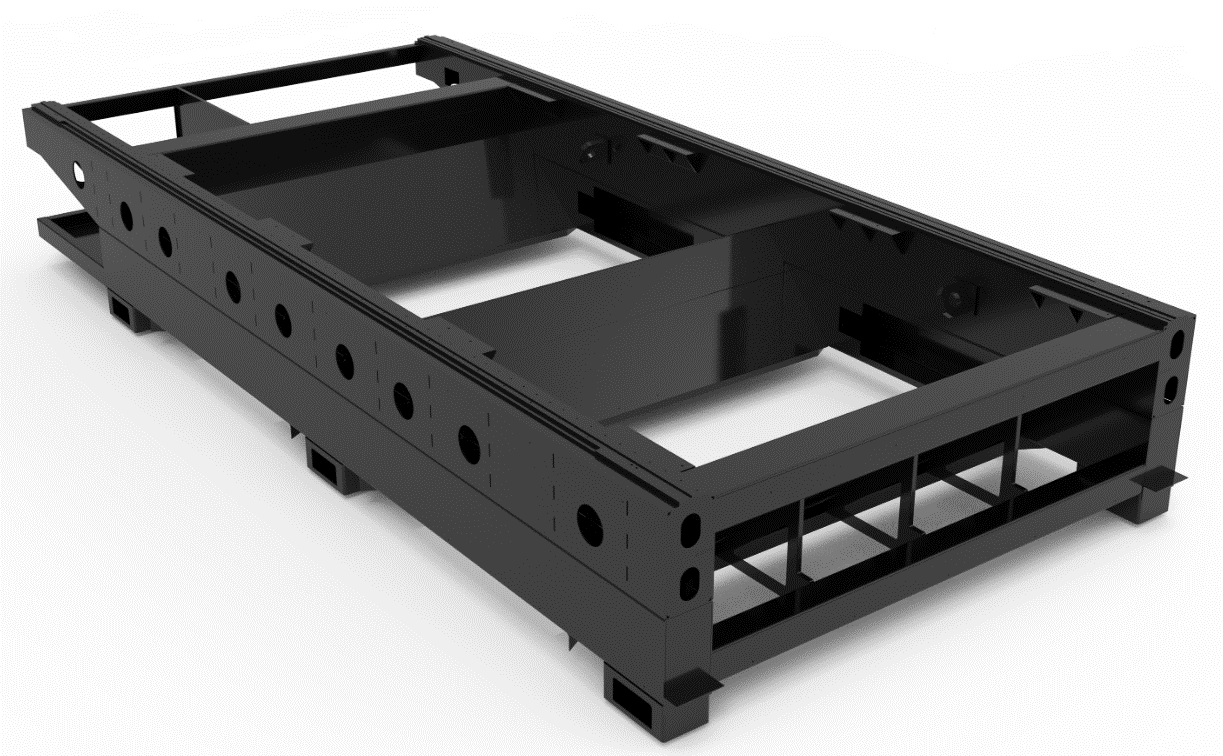

Bed components.

The bed is welded as a whole, treated by annealing to eliminate internal stress, and vibration aging after rough machining before finishing, thus greatly improving the rigidity and stability of the machine tool and ensuring the precision of the machine tool. Through the numerical control system to control its AC servo motor drive, motor drive rack and pinion to achieve the Y direction of reciprocating motion, to achieve rapid movement; Y-axis rack and pinion and linear guide are used in high-precision products, which effectively ensure the accuracy of the transmission; travel both ends of the limit switch control, and at the same time is equipped with a hard limit device, which effectively ensures the safety of the machine tool movement; the machine tool is equipped with automatic lubrication device, timed to the body of the bed of the moving parts to add lubricant to ensure that the movement of the body of the bed of the The machine is equipped with an automatic lubrication device, which adds lubricant to the moving parts of the bed at regular intervals to ensure that the moving parts are running in good condition, which can improve the service life of the guide rail, gear and rack.

The bed is fitted with a toolbar holder with a number of rows of toolbars carrying flat plates.

Crossbeam components

X-axis frame beams are annealed to eliminate internal stress, rough machining and then vibration aging to ensure the rigidity and stability of the laser head moving parts. The bed is equipped with high quality linear guides, driven by servo motors, and driven by high quality rack and pinion, so that the Z-axis slide realises reciprocating motion in the X direction. In the process of movement, the limit switch controls the travel to limit, and at the same time, there are elastic buffer pads at both ends of the mechanical limit, to ensure the safety of the system operation.

Z-axis components

The laser head connecting plate is thicker, has reinforcement ribs, and has optimized weight;

The sheet metal has added heat dissipation holes for the motor and electrical proportional valve;

The Z-axis has added volumetric quantitative lubrication.

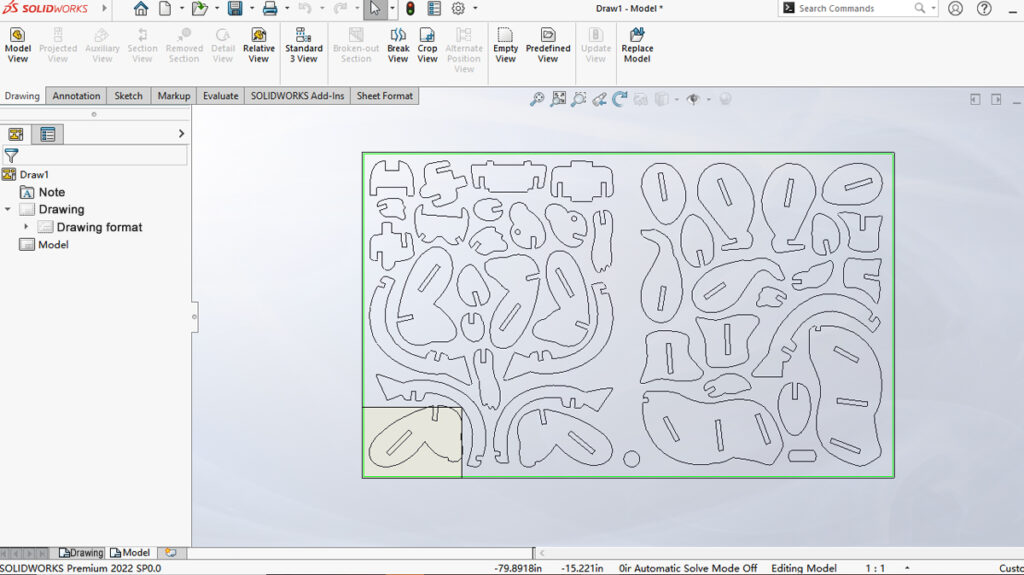

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Laser plate.

Libraries of functions that speed up and simplify design on the plate.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.