JQ-1530HP

Start off on the right foot

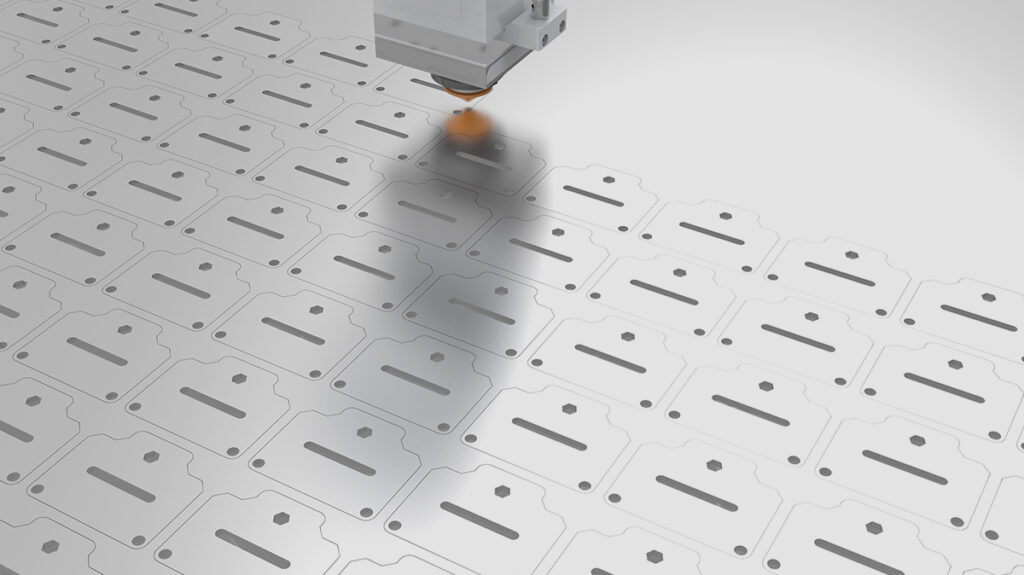

Plate cutting

Power available

6 – 12KW

Loading weight

1500KG

Arbeitsbereich: 3000*1500mm

Verfahrweg der X-Achse: 1520 mm

Verfahrweg der Y-Achse: 3020 mm

Verfahrweg der Z-Achse: 300 mm

The best of technology in the smallest member of the family

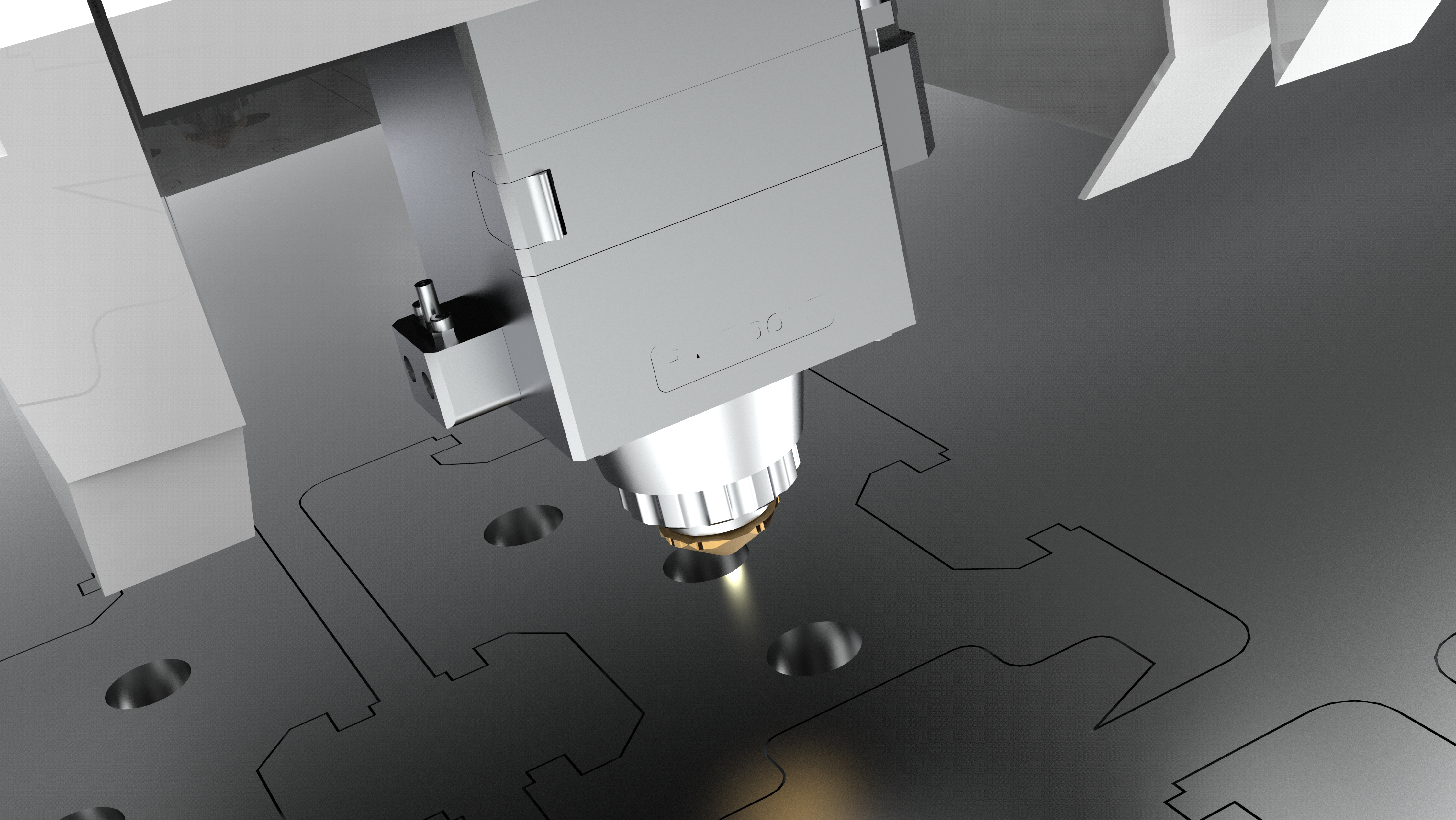

Equipped with the new Plate Cutter cutting head on the JQ-1530HP, you will produce high-quality parts. With automatic focus and integrated laser parameter management, adjustments are unnecessary.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

Shipping solutions such as shipping in a container without removing sheet metal and beams

1. Bus CNC System

2. Dual-motor Driven Exchange Platforms

3. Eco-friendly Cutting by Zoning Ventilation

4. Carbon Steel Welded Machine Bed

Form and content in a single solution

The best choices show their value over time

Plate laser cutting is an efficient and reliable means of processing metal plates. The laser technology offers precise cuts with minimal heat distortion and burring, making it ideal for creating intricate parts for a wide array of industries. It can quickly cut any size plate with high accuracy, producing clean, burr-free edges. In addition to its accuracy and reliability, plate laser cutting offers considerable cost savings over traditional machining processes. This results in a faster turnaround time and lower overall production costs, allowing companies to maximize their profits while providing quality products that meet customer expectations. Plate laser cutting also requires minimal maintenance compared to other metalworking processes, resulting in fewer downtime interruptions due to equipment repairs or replacements. With its precision and cost-effectiveness, Laserschneiden von Blechen is the best choice for manufacturers looking for long-term value.

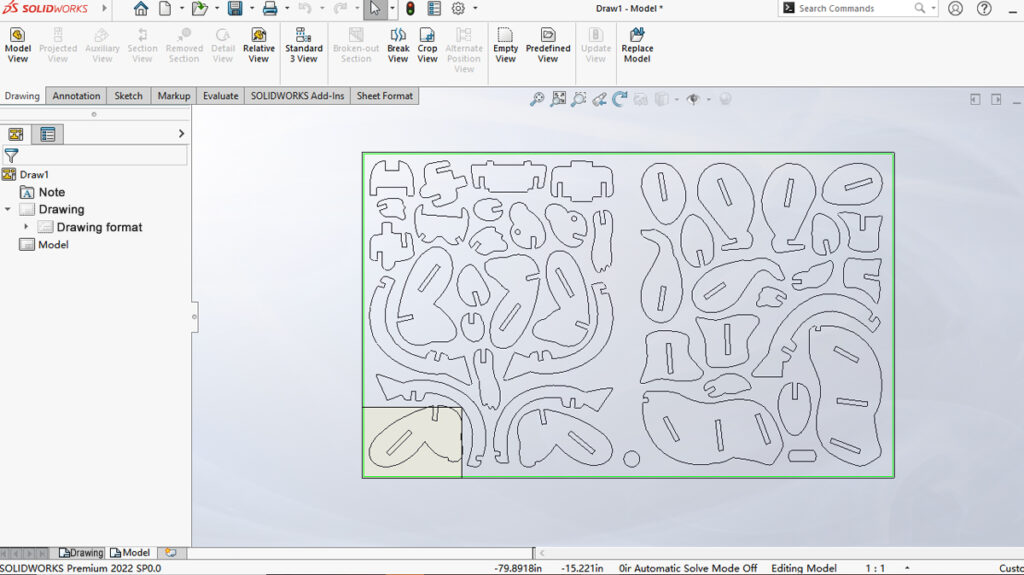

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Laser plate.

Libraries of functions that speed up and simplify design on the plate.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.