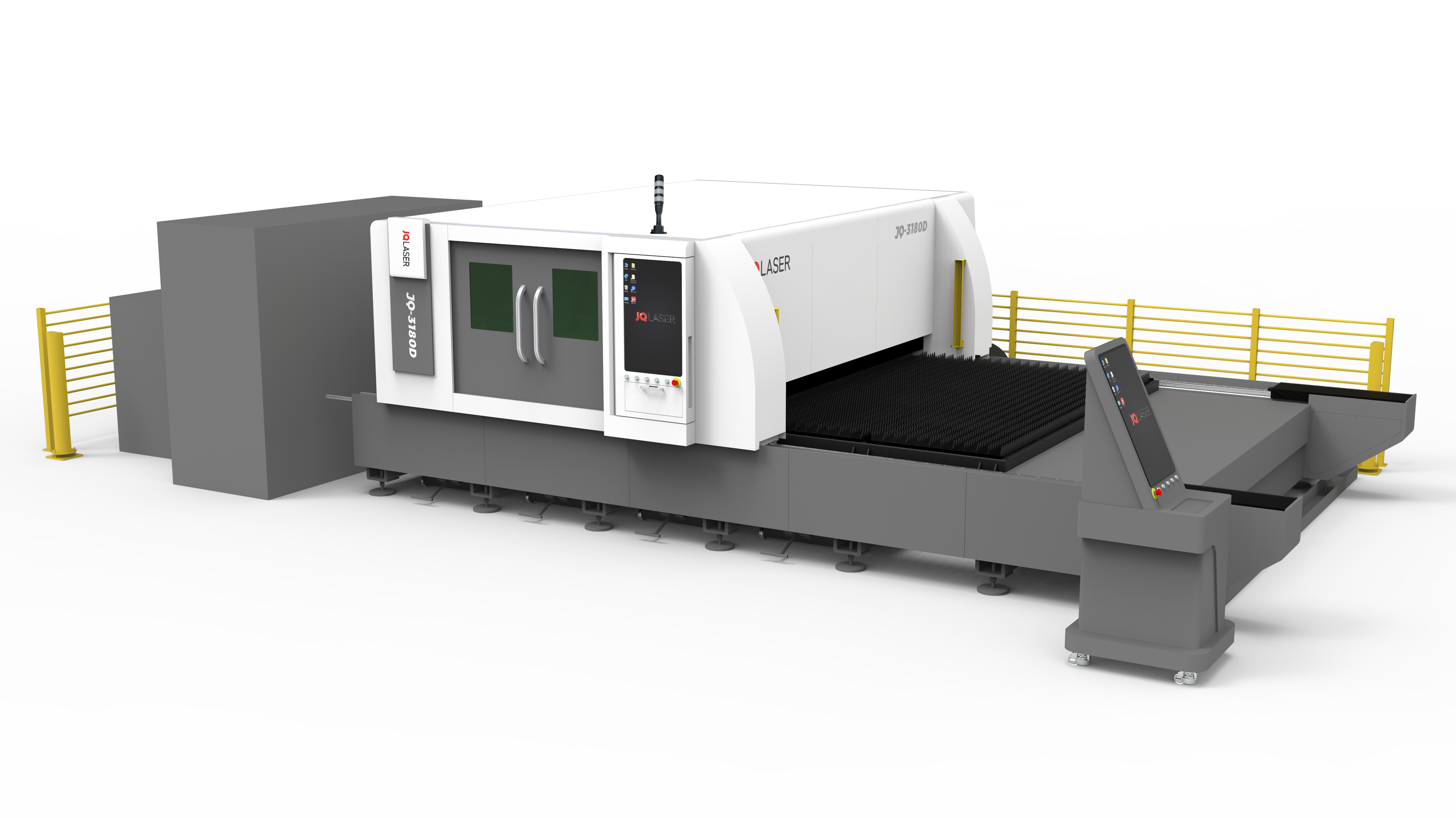

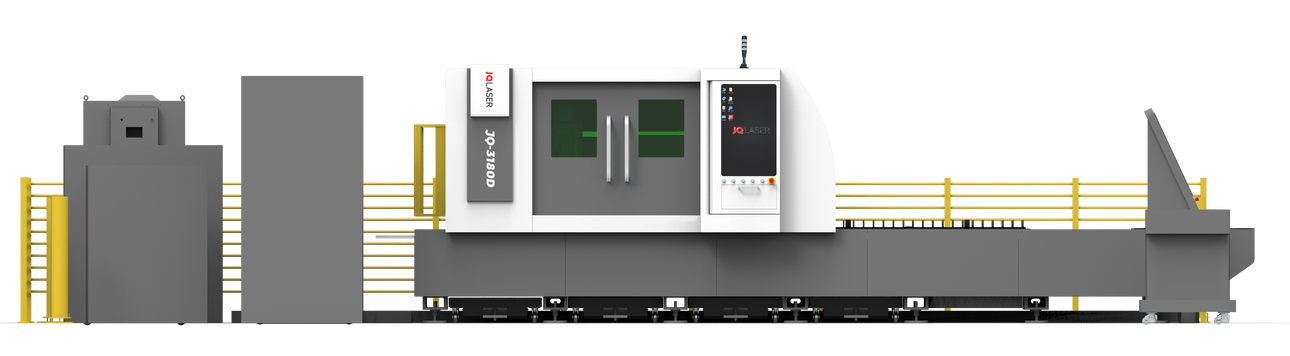

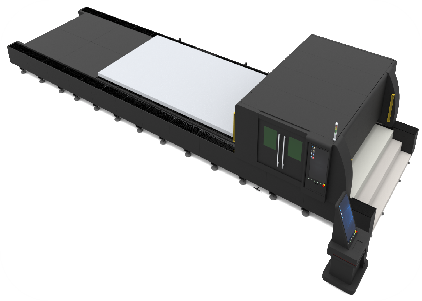

JQ-3180D

Start off on the right foot

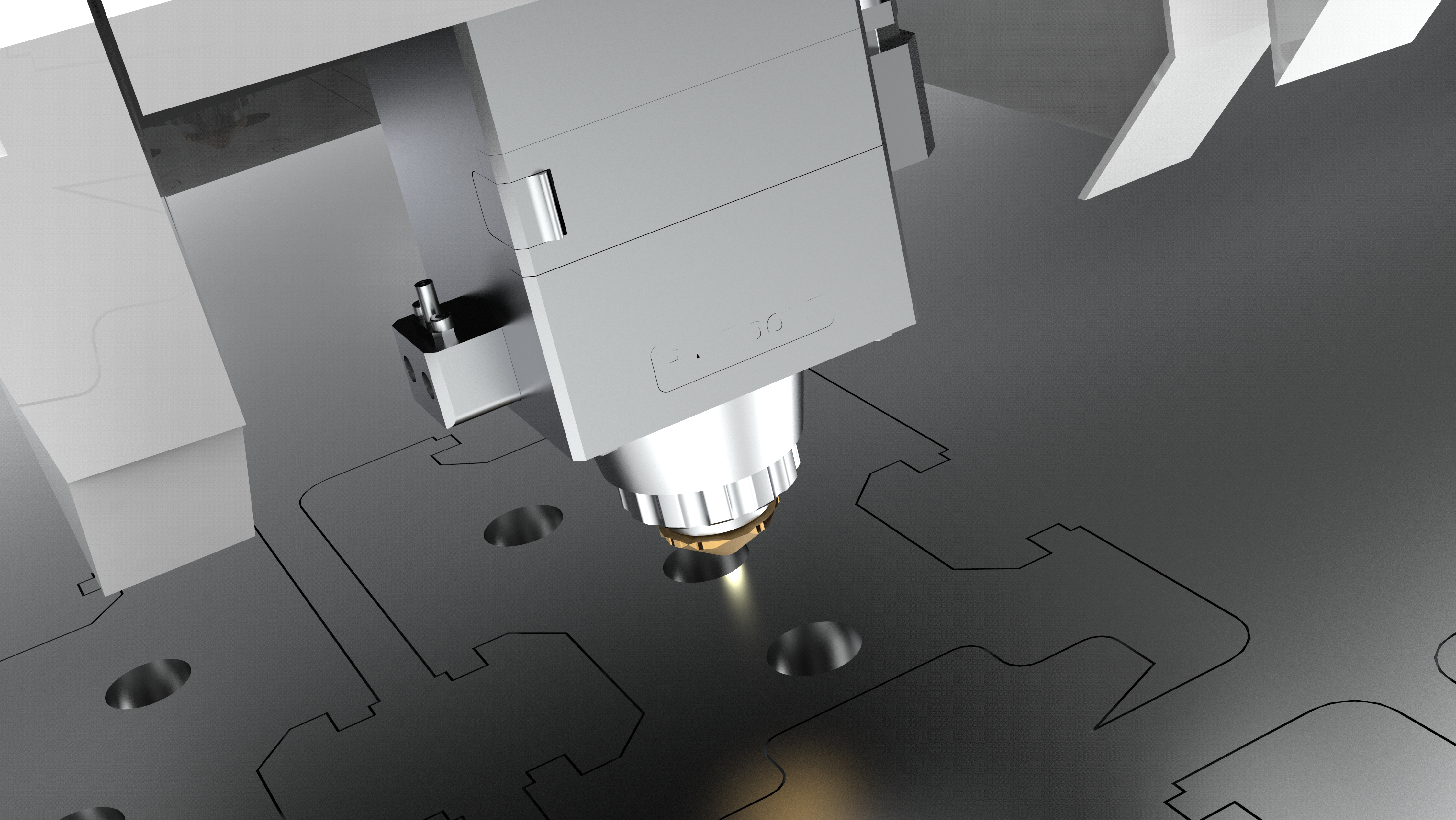

Plate cutting

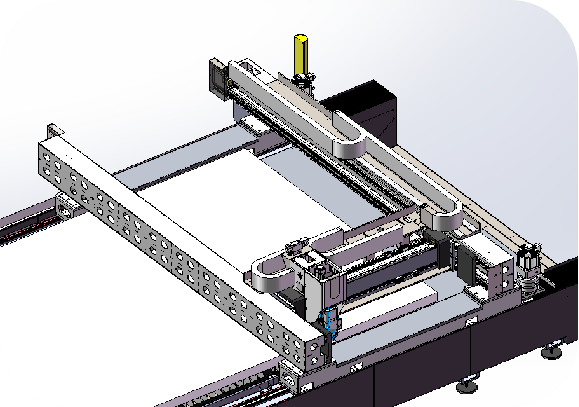

4-axis

Three scene cuts

Loading weight

10000KG

Arbeitsbereich: 3100*8000mm

Verfahrweg der X-Achse: 1250mm

Verfahrweg Y1-Achse: 8000mm

Verfahrweg der Y2-Achse: 3100mm

Verfahrweg der Z-Achse: 150 mm

Main indicators of 3180D project:

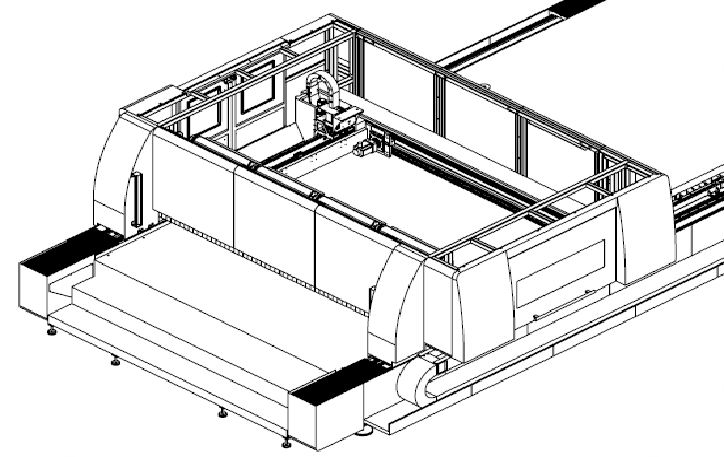

- Realize large-format four-axis; can realize three scene cutting, scene 1: small contour range 3X1.25 meters by X, Y2, Z axis cutting inside the beam; scene 2: simple contour larger than 3X1.25 meters by X, Y1, Z axis cutting; scene 3: complex contour larger than 3X1.25 meters by X, Y1, Y2, Z axis cutting;

- Realize high efficiency and modularization of products;

Improve processing efficiency, facilitate operation, and optimize structure; - Verbessern Sie die Integrität und Korrektheit.

- Uniformity of process documents and equipment information;

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

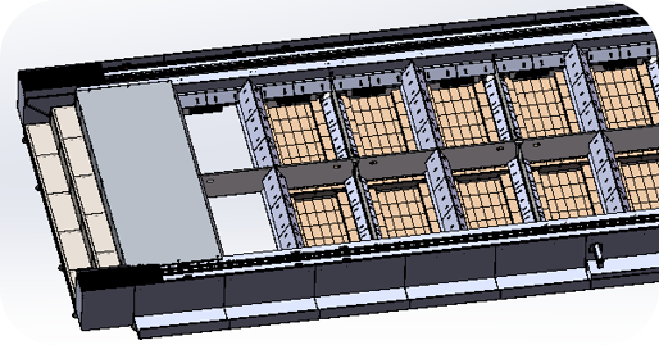

Design of flue of bed

The size of the partition dust removal port is 120*400mm, and the ventilation area is +30%;

The flap valve is replaced, and the design without partition greatly reduces the wind resistance coefficient;

A Y-shaped galvanized air duct is set on the back side of the bed, and the air duct outlet is set on the back side of the bed, which is convenient for on-site installation.

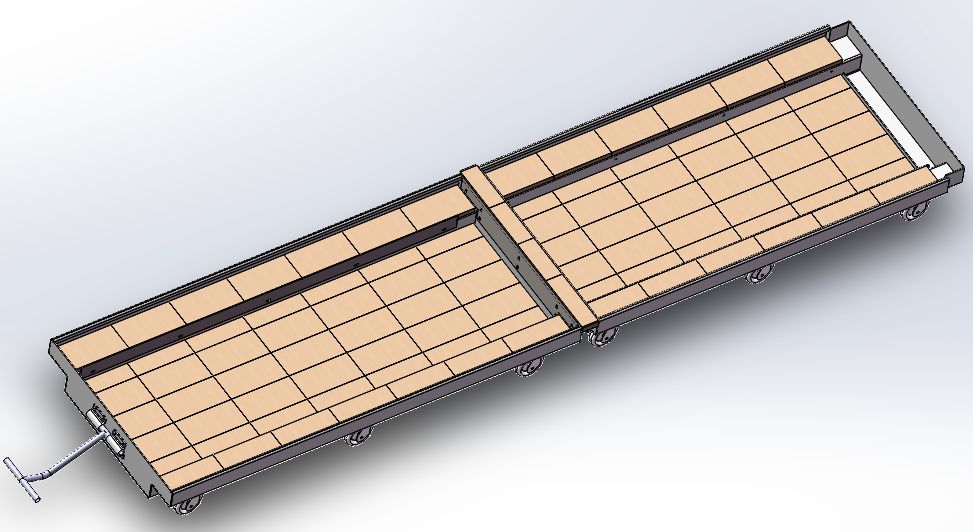

Lifting of material cart:

The handle adopts a T-shaped mechanism, which is easy to push and pull with both hands, and is warped upward at the same time, which is convenient for workers to quickly get started;

The main structure of the box adopts an inverted “J” bend, and is paved with fireproof bricks, which can effectively enhance the structure and reduce thermal deformation;

The bed is equipped with a guide structure + limit baffle, which is easy to push and pull the material cart.

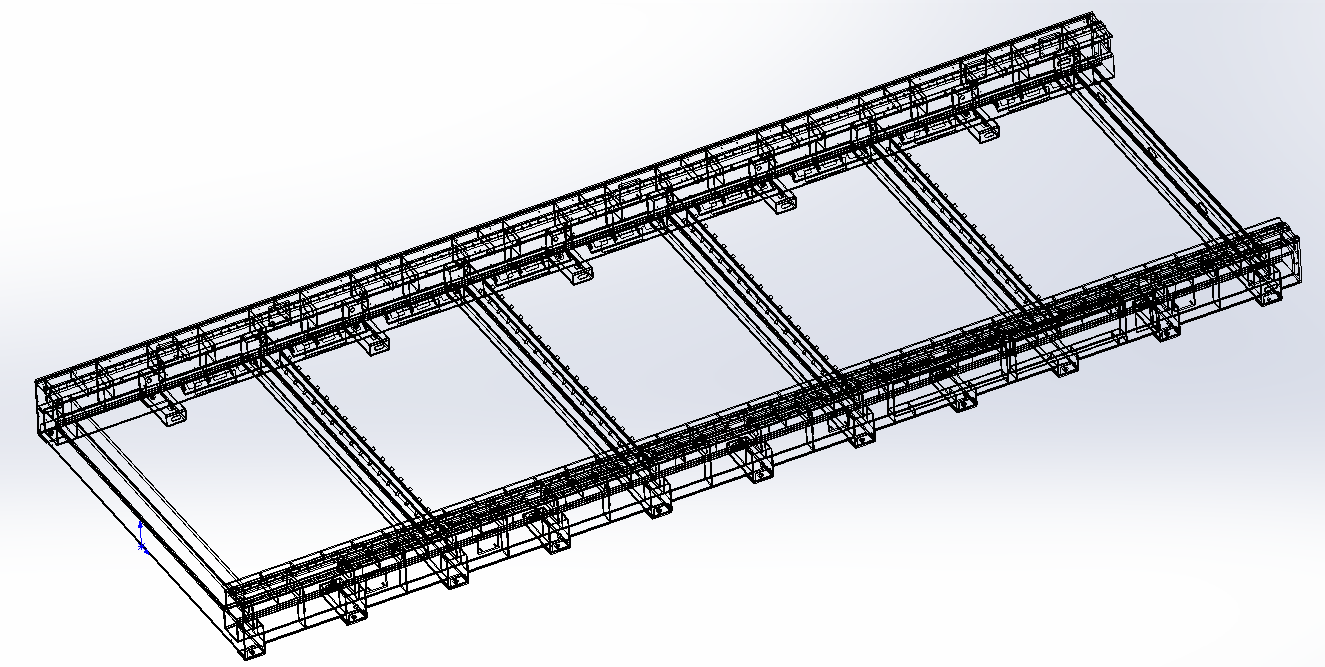

The bed structure adopts a plate-welded box-type frame structure, with reasonable arrangement of rib plates and plug-in structure at key connection points. Under the premise of maximum strength use, the laser burning area is reduced to avoid thermal deformation of the bed. At the same time, strict welding process is formulated, and annealing and stress relief treatment are carried out to ensure the stability of the bed.

Selection of equipment anti-burning materials

A. The main body of the bed is paved with cast iron plates, which are resistant to burning and heat insulation and convenient for users to clean slag;

B. The work surface is equipped with a graphite plate, which can effectively prevent the laser from burning and thermal deformation of the surface; C. The scrap car is paved with high-alumina refractory bricks, which can effectively prevent the laser from burning and thermal deformation of the scrap car;

The equipment is equipped with two operating stations and displays :

One is on the removable protective cover, which allows the operator to observe the actual cutting of the workpiece while operating the equipment.

The other one is on the front side of the equipment, which can reduce the operator’s moving distance and reduce the work intensity. Customers can freely choose according to the usage scenario , which is convenient for customers to use.

The two operating devices are interlocked. If one is operated, the other cannot be operated, ensuring safe operation of the equipment.

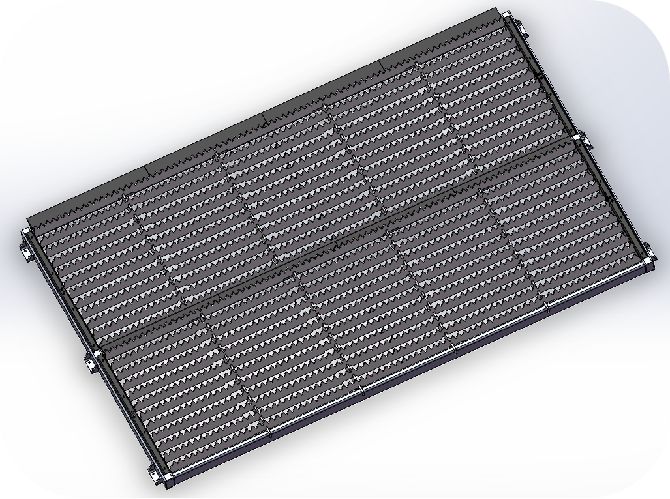

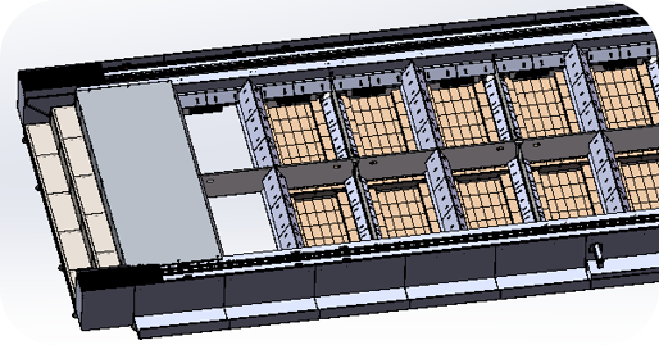

Countertop frame components:

Adopt modular arrangement of blades; The knife tips are staggered to provide effective three-point support; anti-burning blades, adopts graphite plate to increase service life, and easy to clean the facilitate slag.

Receiving box:

The handle is T- shaped structure, which is easy to push and pull with both hands, and is also warped upwards, making it easy for workers to get started quickly;

The main structure of the box adopts an inverted ” J ” -shaped bend and is paved with high-alumina refractory bricks, which can effectively strengthen the structure and reduce thermal deformation;

The machine base is equipped with a guide structure + limit baffle to facilitate the push and pull of the material cart.

Dust extraction system inside sheet metal hood :

The cutting area is equipped with a protective cover to effectively limit the damage to the human body caused by laser beams, cutting smoke, etc.

The equipment is equipped with a cross-flow fan design to ensure timely collection of smoke and dust. A special smoke integrator is installed on the rear side to effectively collect the internal smoke and heat .

Design of exhausr system:

The size of the partition dust removal opening is 120*400mm , and the ventilation area could increase 30% ;

Replace the flap valve with a partition-free design, which greatly reduces the wind resistance coefficient;

The equipment is set with cross partitions in front, back, left and right, which can realize zoned dust removal and effectively utilize the capacity of the smoke dust collector;

Y- shaped galvanized air duct is installed on the rear side of the bed , and the air duct outlet is set on the rear side of the bed to facilitate on-site installation .

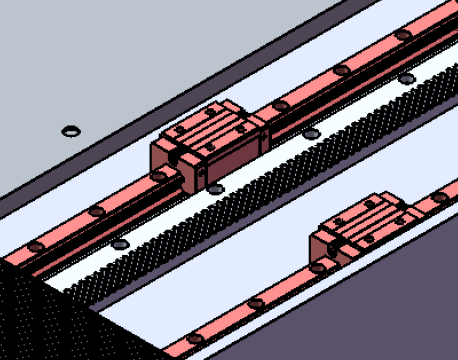

Z -axis head adopts a fully enclosed structure:

The screw guide rail has an added bellows cover protection and is provided with sheet metal protection during processing to achieve sealing while preventing damage to the bellows cover.

The laser head is also protected by sheet metal on the outside and a dust cover on the bottom to increase its service life . Add forced heat dissipation holes for motors and electrical proportional valves

Safty configuration:

The front / side of the front bed is equipped with pedals to facilitate loading and unloading easily;

Two sets of safety light curtains are installed in front and back of the sheet metal shield to prevent collisions when users are unloading materials at the same time;

A separate camera is installed on the rear side of the sheet metal, which is convenient for observing the equipment status while operating the equipment;

The equipment is equipped with at least 3 emergency stop switches, on the left side + right side of the sheet metal protection + movable operating table; Optical fiber plug-free design.

The best choices show their value over time

The crossbeam is equipped with a protective cover to meet safety standards. There are observation ports on both sides of the crossbeam, and there are cameras inside to facilitate customers to observe the processing status.

The bed structure adopts a plate-welded box-type frame structure, with reasonable arrangement of rib plates, and a plug-in structure for key overlaps. Strict welding processes are formulated, and annealing and stress relief are carried out to ensure the stability of the bed.

The crossbeam adopts a steel crossbeam + aviation-grade high-strength aluminum alloy, and the steel crossbeam adopts a plug-in structure. The middle extruded aluminum profile structure adopts an outer square inner circle + cross partition composite structure. While being lightweight, each force-bearing surface is individually provided with reinforcing ribs to enhance the dynamic response of the movement to the extreme.

Two monitors, customers can freely choose according to the usage scenario, which is convenient for customers to use.

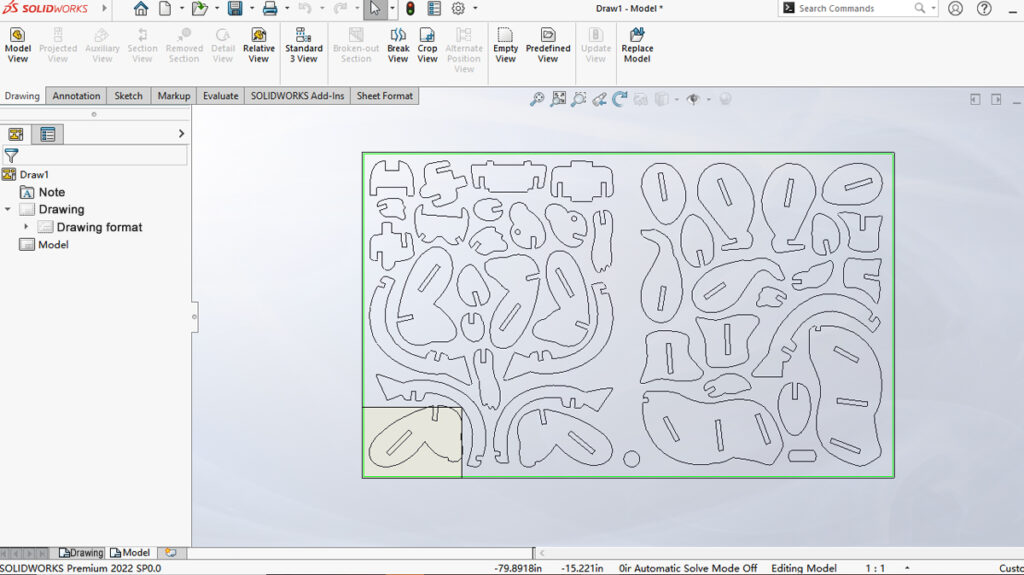

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Laser plate.

Libraries of functions that speed up and simplify design on the plate.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.