Laser cutting is a modern manufacturing process that utilizes focused light energy to cut through various materials with high precision. The term “laser” stands for “light amplification by stimulated emission of radiation,” which describes how lasers work by concentrating light to produce extreme temperatures that melt or vaporize materials. This technology has transformed traditional manufacturing methods, offering a level of accuracy and efficiency that was previously unattainable.Laser cutting operates by directing a high-powered laser beam onto the material surface, which either melts or vaporizes the material, allowing for clean cuts. The process can be adjusted for different thicknesses and types of materials, making it incredibly versatile. Industries ranging from automotive to aerospace rely on laser cutting for its ability to produce complex shapes and designs with minimal waste and maximum efficiency.This technology is widely used across multiple industries due to its versatility and efficiency. Common materials processed through laser cutting include metals such as mild steel, stainless steel, aluminum, as well as non-metals like wood, plastics, and ceramics. The evolution of laser cutting technology has significantly improved accuracy and speed, making it an essential tool in modern manufacturing. With advancements in laser technology, manufacturers can achieve tighter tolerances and faster production times, which are critical in competitive markets.

Advantages of Laser Cutting

- Präzision: Laser cutting offers unparalleled accuracy, allowing for intricate designs and complex geometries that are difficult to achieve with traditional cutting methods. This level of precision is crucial in industries where even the slightest deviation can lead to significant issues in functionality or appearance.

- Vielseitigkeit: This method can cut a wide range of materials, making it suitable for various applications across different industries. Whether it’s creating delicate components for electronics or robust parts for machinery, laser cutting can adapt to the specific needs of each project.

- Reduced Waste: The precision of laser cutting minimizes material waste, contributing to cost savings and environmental sustainability. By ensuring that cuts are made exactly where needed, manufacturers can optimize their raw material usage and reduce their overall environmental footprint.

Applications of Laser Cutting

Laser cutting is used in numerous applications, including:

- Manufacturing: Creating parts for machinery and equipment is one of the most common uses of laser cutting. Manufacturers can quickly produce high volumes of components with consistent quality.

- Signage: Producing detailed signs and displays requires both precision and creativity. Laser cutting allows designers to create intricate patterns and lettering that stand out.

- Aerospace: Fabricating components with strict tolerances is essential in the aerospace industry. Laser cutting enables manufacturers to produce lightweight yet strong parts that meet rigorous safety standards.

- Automotive: Manufacturing body parts and components involves complex shapes and high precision. Laser cutting helps automotive manufacturers streamline their production processes while maintaining quality.

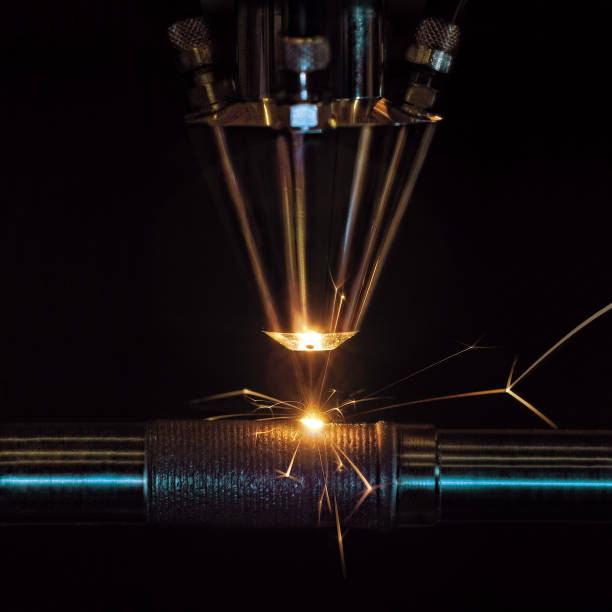

Exploring Laser Cladding Technology

Laser cladding is an advanced additive manufacturing process that involves the deposition of material onto a substrate using a laser beam. This technique is primarily used to enhance the surface properties of components by creating a metallurgical bond between the substrate and the deposited material. Unlike traditional welding or coating methods, laser cladding offers superior control over the thickness and quality of the applied layer.In laser cladding, filler materials—often in powder form—are introduced into the laser beam’s path, where they are melted and fused with the substrate. This process results in a hard-wearing surface that can significantly improve wear resistance, corrosion resistance, and overall durability. The ability to apply different materials allows manufacturers to tailor surface properties according to specific application requirements.

Benefits of Laser Cladding

- High Precision: Like laser cutting, laser cladding allows for precise control over the deposition process, resulting in high-quality finishes. The fine focus of the laser beam ensures that only targeted areas are affected, preserving the integrity of the surrounding material.

- Material Versatility: Various materials can be used for cladding, including ferrous and non-ferrous alloys, which enhances the adaptability of this technology. This versatility enables manufacturers to select optimal materials based on performance requirements such as hardness or thermal resistance.

- Low Heat Input: The localized heating minimizes thermal distortion and damage to the underlying substrate, making it suitable for delicate components. This characteristic is particularly advantageous when working with heat-sensitive materials or intricate geometries.

Applications of Laser Cladding

Laser cladding finds applications in several industries, such as:

- Oil & Gas: Repairing and refurbishing critical components like drilling equipment is essential for maintaining operational efficiency. Laser cladding can restore worn parts while enhancing their resistance to harsh environmental conditions.

- Aerospace: Enhancing turbine blades and other high-performance parts is crucial for ensuring reliability under extreme conditions. Laser cladding allows for precise modifications that improve performance without compromising structural integrity.

- Manufacturing: Restoring worn-out molds or tooling helps extend their lifespan while maintaining production quality. By applying new material through laser cladding, manufacturers can reduce costs associated with replacing expensive tooling.

Key Differences Between Laser Cutting and Laser Cladding

While both laser cutting and laser cladding utilize lasers for processing materials, they serve distinct purposes within manufacturing:

| Merkmal | Laser Cutting | Laser Cladding |

|---|---|---|

| Purpose | Cut through materials | Deposit material onto surfaces |

| Process Type | Material removal | Additive manufacturing |

| Heat Affected Zone | Larger heat affected zone | Minimal heat affected zone |

| Material Types | Metals, plastics, wood | Primarily metals and alloys |

| Präzision | High precision cuts | High precision deposits |

| Application Focus | Creating parts | Repairing or enhancing surfaces |

Understanding these differences is crucial for manufacturers when selecting the appropriate technology for their specific needs. Each method offers unique advantages that cater to different aspects of production processes.

The Synergy Between Machining and Laser Cladding

Machining is a traditional manufacturing process that involves removing material from a workpiece to achieve desired shapes and dimensions. When combined with laser cladding, machining enhances the effectiveness of repairs and refurbishments by providing a clean surface for cladding application. This synergy between processes allows manufacturers to maximize efficiency while ensuring high-quality results.

Benefits of Combining Machining with Laser Cladding

- Precision Surface Preparation: Machining ensures surfaces are properly contoured for optimal adhesion during the cladding process. A well-prepared surface allows for better bonding between layers, resulting in enhanced performance characteristics.

- Enhanced Material Properties: By removing degraded material before cladding, components can achieve improved characteristics such as higher hardness or better corrosion resistance. This step ensures that only high-quality material contributes to the final product’s properties.

- Cost-Efficiency: This integrated approach reduces material costs by focusing on repairing rather than replacing entire components. Manufacturers can save significantly by extending the life cycle of existing parts rather than investing in new ones.

- Extended Component Lifespan: The combination leads to more durable components that require less frequent maintenance or replacement. This longevity translates into lower operational costs over time.

- Sustainable Practices: Refurbishing existing components helps conserve resources by reducing the need for new materials. This approach aligns with growing sustainability initiatives within various industries aimed at minimizing waste and environmental impact.

Comparing Cost Factors in Laser Technologies

When evaluating laser cutting versus laser cladding from a cost perspective, several factors must be considered:

Initial Investment

Both technologies require significant initial investments in equipment; however, laser cladding systems tend to be more expensive due to their complexity and precision requirements. The cost difference reflects not only the machinery itself but also the necessary training for operators who must understand both processes thoroughly.

Operational Costs

Operational costs can vary based on energy consumption, maintenance needs, and labor requirements:

- Laser Cutting:

- Generally lower operational costs due to faster processing times compared to other methods.

- Higher energy consumption when cutting thicker materials may offset initial savings if not managed properly.

- Laser Cladding:

- More energy-efficient due to automated processes that optimize resource usage.

- Requires skilled operators leading to potentially higher labor costs; however, this investment pays off through improved quality control.

Long-Term Savings

Both technologies offer long-term savings through reduced material waste and enhanced product quality:

- Reducing defects leads to fewer reworks or replacements over time.

- Improved durability extends product lifespans, lowering overall production costs as fewer replacements are needed throughout a component’s lifecycle.

Future Trends in Laser Technologies

As industries continue to evolve, so do the technologies associated with laser cutting and cladding. Emerging trends include:

- Automation Integration: Increased automation will streamline processes in both laser cutting and cladding applications by minimizing human error while maximizing efficiency through advanced robotics systems.

- Advanced Materials: Research into new alloys and composite materials will expand the capabilities of both technologies; this innovation enables manufacturers to explore new applications previously deemed impractical due to material limitations.

- Sustainability Focus: As environmental concerns grow among consumers and regulators alike, manufacturers will seek processes that minimize waste generation while optimizing energy consumption throughout production cycles.

- Enhanced Software Solutions: Improved software for design modeling will optimize both processes for better efficiency; these advancements allow engineers greater flexibility when designing complex geometries suited specifically toward either method’s strengths.

- Hybrid Technologies: The combination of different manufacturing processes may lead to innovative solutions that leverage strengths from both laser cutting techniques alongside additive approaches like those found within traditional welding practices—ultimately enhancing overall productivity levels across multiple sectors involved within engineering disciplines today!

Conclusion on Choosing Between Technologies

When deciding between laser cutting and laser cladding technologies it is essential consider specific project requirements such as material types desired outcomes cost implications operational capabilities involved each method offers unique advantages cater different aspects manufacturing—from creating intricate parts through precise cuts enhancing component durability via effective surface treatments understanding these differences comprehensively allows manufacturers make informed decisions align production goals maximizing efficiency quality across operations!