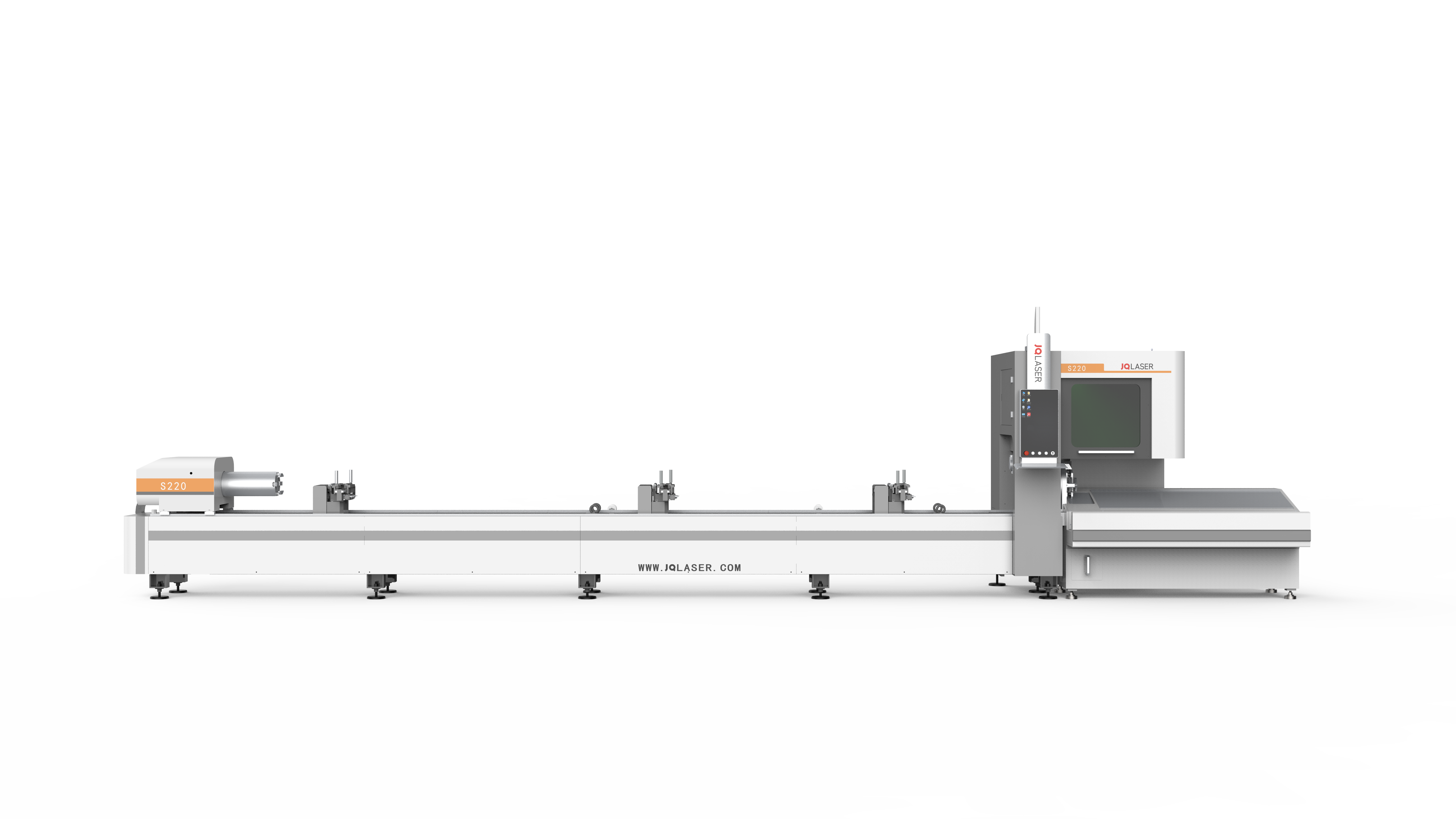

S220

Start off on the right foot

Round, square,

rectangular tubes

3D

160 kg

(15 to 220 mm)

The best of technology in the smallest member of the family

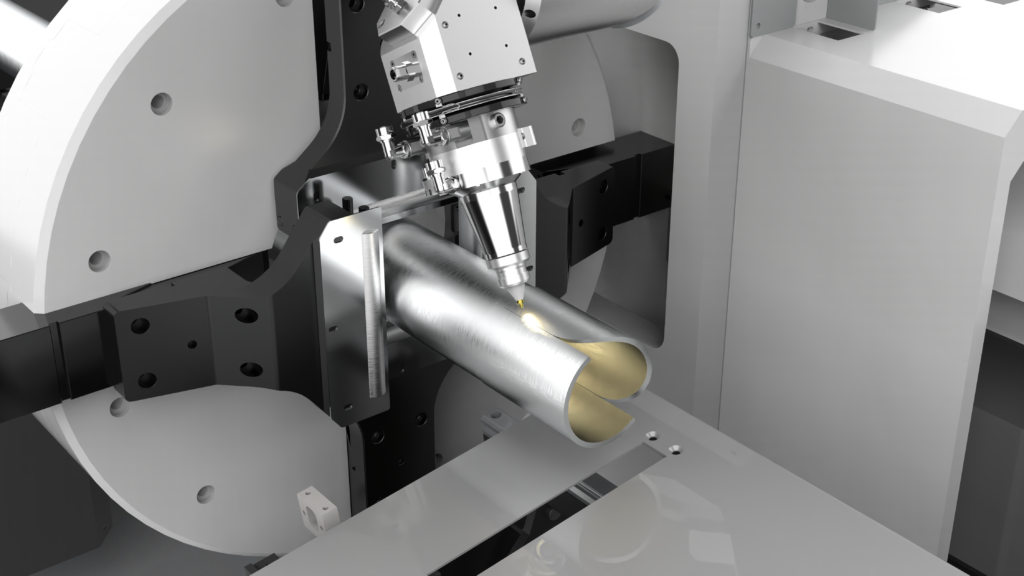

With the new TubeCutter cutting head equipped on the S220, you will produce high quality parts. With automatic focus and integrated laser parameter management, there is no need for adjustments.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

The main part of the machine tool is the main component of the entire fiber optic pipe cutting machine. The cutting function and cutting function of the fiber optic pipe cutting machine are

The cutting accuracy is achieved by the main machine part, which consists of the bed, front chuck, rear chuck, cross beam and x-axis device, z

Axis device, laser head, follow-up support, auxiliary system (lubrication, air path and water path), electric control cabinet, operation screen, operation panel

composed of other parts.

Form and content in a single solution

The best choices show their value over time

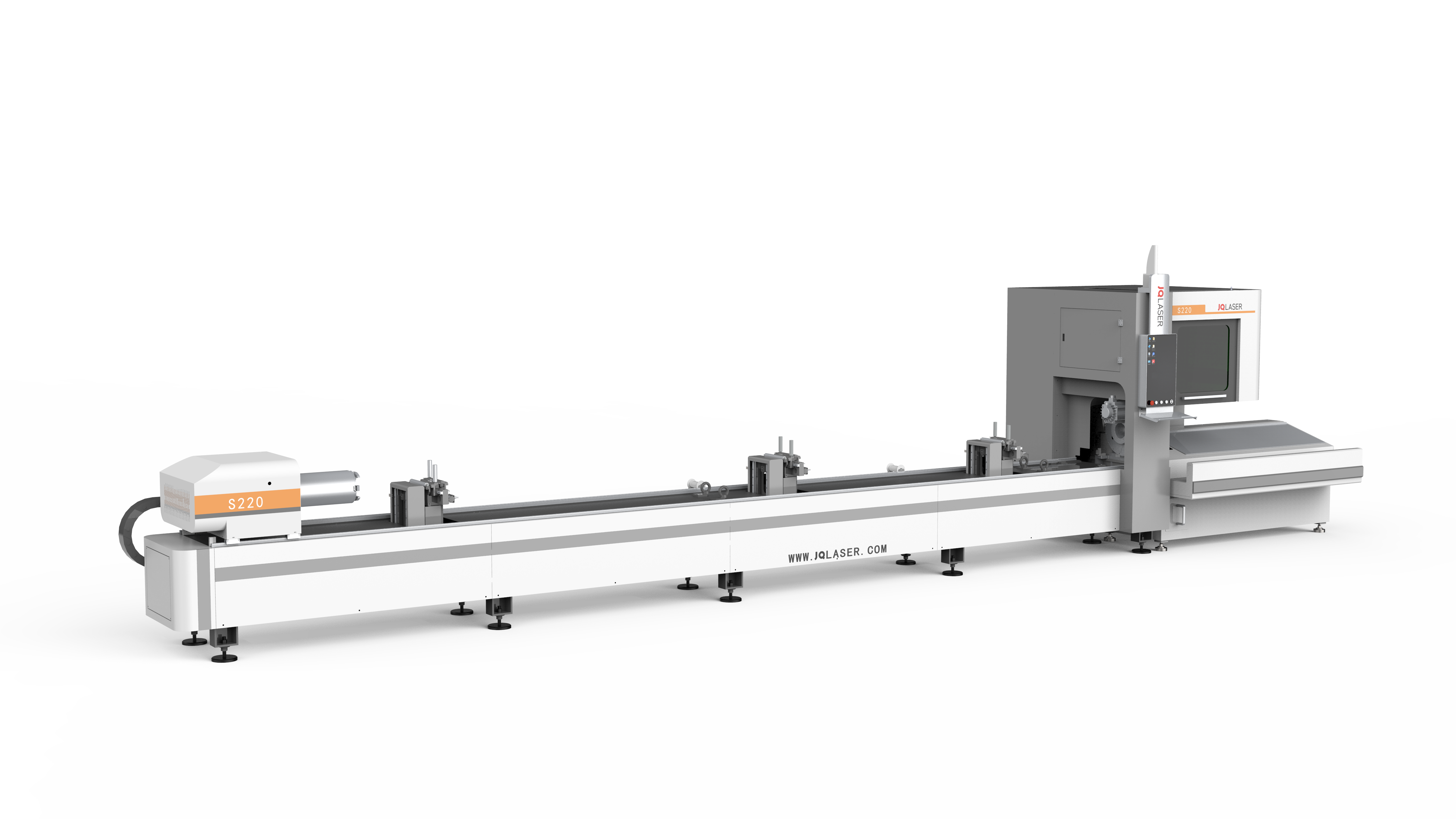

There are 3 sets of roller support mechanisms installed on the bed. The auxiliary support is mainly for cutting longer pipes (pipes with smaller diameters).

For auxiliary control of excessive deformation, the cylinder controls the up and down movement of the support on the auxiliary support. When the rear chuck moves to the corresponding

At the position, the auxiliary support can be lowered to avoid it. For pipes of different sizes, please use the corresponding support radius to adapt to the pipe.

the height of.

Machine performance will remain robust, reliable and productive year after year.

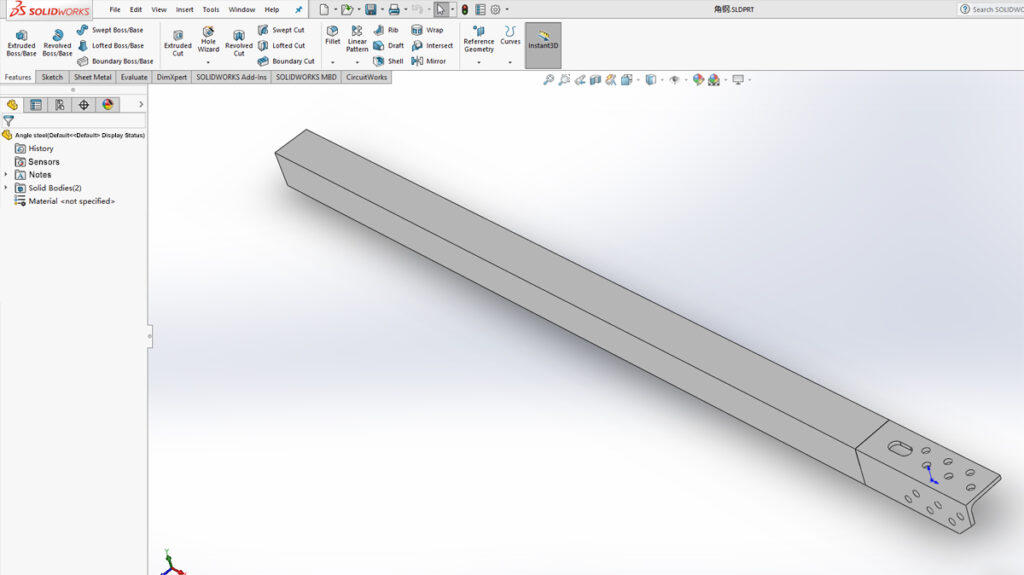

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.