In today’s modern society, having the ability to accurately and efficiently cut various materials is essential for businesses in a wide range of industries. It is important for those involved in engineering and manufacturing to have the latest technology available to them that can make their workload easier. One such device is the tube laser cutting machine, which has rapidly become one of the most popular tools used by manufacturers around the world.

Tube Laser Cutting

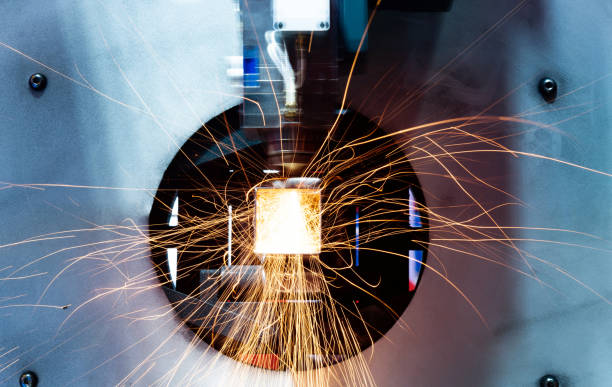

Tube laser cutting is an innovative technology that is revolutionizing the way materials are cut. The tube laser cutting machine has taken the place of traditional torch-based cutting techniques that have been used for decades. This technology uses a powerful and precise beam of light to cut through steel, aluminum, brass and other metals quickly and accurately.

The ability to cut tubes with a high degree of accuracy is what makes this type of machine so valuable. This precision allows for complex shapes to be created with intricate detail. Furthermore, it eliminates potential safety hazards associated with manual tube cutting processes such as sparks and smoke. With a wide range of materials able to be worked on by this process, it has quickly become an invaluable tool in many industrial settings.

Material Types: Metals

Metals are a popular material choice when it comes to tube laser cutting machines. Their high strength and durability make them an ideal choice for a variety of applications. Metals can be processed into intricate shapes and designs, allowing manufacturers greater flexibility in their design capabilities than ever before.

The most common metals used in tube laser cutting machines are stainless steel, aluminum alloys, brass, and copper alloys. Each metal has its own unique properties that make it suitable for different tasks. Stainless steel is the most commonly used metal due to its high strength-to-weight ratio, corrosion resistance, and good thermal conductivity. Aluminum alloys are lightweight yet strong and offer excellent formability properties. Brass is often chosen for decorative elements as it is easy to polish to a beautiful finish. Copper alloys also provide good electrical conductivity making them ideal for electronic components or wiring components.

Material Types: Plastics

Plastics are one of the most versatile and widely used materials on the planet. With so many varieties available, it’s no surprise that they have become a popular choice for use in tube laser cutting machines. These machines can be used to cut through a variety of plastic materials, including polyvinyl chloride (PVC), acrylic, polyethylene terephthalate (PET) and more.

Using a tube laser cutting machine is an efficient way to accurately cut plastics into complex shapes and sizes. The high-power lasers employed by these machines allow for precise cuts that are far beyond what traditional saws or blades can achieve. This means that even complicated designs can be achieved quickly with minimal material waste. Additionally, using a tube laser cutting machine for plastics often results in smoother surfaces than other methods of cutting them would produce.

Material Types: Glass

Glass is an extremely versatile material that can be cut with a tube laser cutting machine. Its strength and durability make it an ideal component for many different applications, from manufacturing to architectural designs. Additionally, glass offers aesthetically pleasing options for visually appealing projects.

Glass can be processed with a variety of methods such as etching, engraving, and polishing in order to create custom finishes and shapes that are perfect for any project. This allows users to customize their projects according to the specific needs of each application or product type. By using a tube laser cutting machine, glass can be quickly and accurately cut into precise shapes and sizes with minimal waste or damage. It also helps reduce production costs by allowing users to achieve high-quality results without having to invest in additional tools or materials.

Advantages of Tube Laser

Tube lasers are a powerful and versatile tool that can dramatically improve the manufacturing process for many businesses. With the ability to cut through a wide variety of materials, tube laser machines are becoming increasingly popular as an efficient and cost-effective way to produce high-quality products. There are many advantages to using this type of machine, including improved accuracy and speed.

One of the primary advantages of a tube laser is its accuracy. Due to its precise cutting capabilities, it can be used to create highly detailed parts with smooth edges that require minimal post-production work. This not only saves time but also money since less material is wasted during the production process. Additionally, tube lasers can cut through extremely thick materials thanks to their powerful beam which creates clean cuts with minimal distortion or deformation in the material being processed.

Considerations for Laser Cutting Tubes

When using a tube laser cutting machine, it is important to consider the material type, size, quantity, and design requirements prior to production. When selecting a tube laser cutting machine, manufacturers must consider the capabilities of the equipment along with the material and design specifications of the item being produced. Additionally, operators should take into account any potential safety concerns or risks associated with operating such machinery. To ensure optimal performance from the machine, it is essential that operators inspect all components for wear before use and regularly service according to manufacturer guidelines. Furthermore, ensuring that all workers have received proper training on how to safely operate a tube laser cutting machine will help reduce any potential hazards during production.

Conclusión

It is a versatile and powerful tool for creating complex shapes. It has wide applications in many industries, including fabricación de automóviles, aerospace engineering, and prototype development. The various metals and non-metals that can be cut with a tube laser make it an invaluable asset in these fields. With its efficiency and accuracy, the tube laser cutting machine makes quick work of complicated designs.

The consistency of the cuts made by this machinery is one of the top reasons why it has become such an important tool in industry. The high-precision cuts produced by the tube laser cutter are precise enough to create intricate parts or prototypes to close tolerances with minimal time and effort. Whether for large batches or small production runs, businesses rely on its accuracy to get their products manufactured quickly and efficiently.