HL-1250S

Begin on the correct path

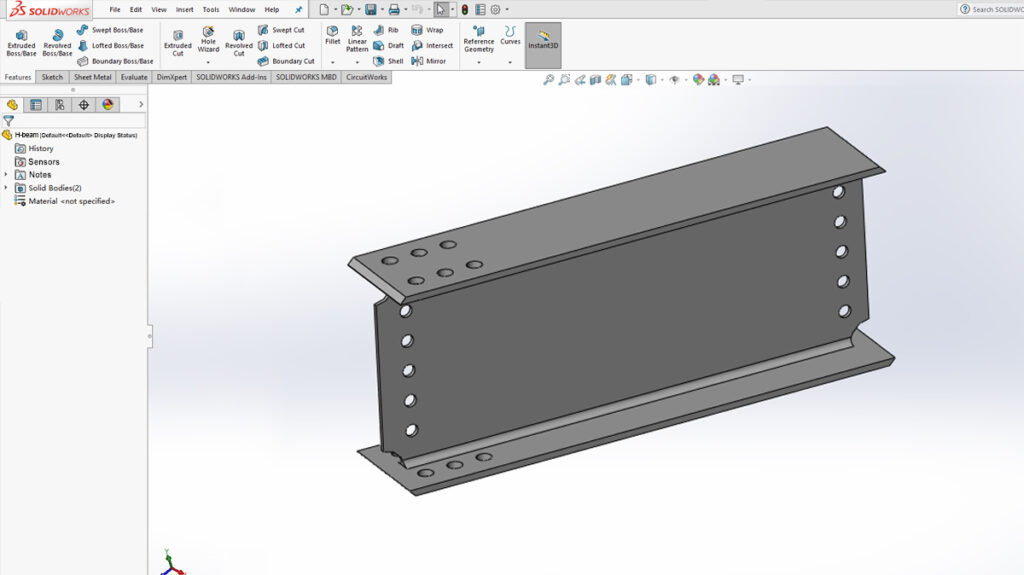

Cutting, bevel cutting, hole cutting, welding notch cutting

3D

55

X-axis travel:2200mm

Y-axis travel:38500mm

Z-axis travel:1150mm

The best of technology in the smallest member of the family

- Gantry type girder design

- Fast transport speed

- High precision and high stability.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

Double guide. High precision 1-rack installation.

Form and content in a single solution

The best choices show their value over time

Dust collection and fireproofing installation

The dust collector is installed on the main beam and moves along it to ensure dust collection effect. The electrical cabinet and cooling chiller, laser generator are installed next to the machine and do not move along the cross member.

Third parties install the generator and cooling chiller on the main beam. This way, there is no limit to the working length. You can extend it without limitation. However, if you carry and move heavy parts on the jib-type main beam for a long time, it will have some effect on the equipment and processing.

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.