Industria de torres de hierro

As the world progresses, so too does the technology that we use to get ahead. One such technology is laser cutting, which has a wide range of applications in many industries. The iron tower industry is one that has seen rapid growth in recent years, and our company has been at the forefront of this growth. With our extensive industry expertise, we have been able to help leverage laser cutting technology to help the iron tower industry grow even faster. This technology has allowed us to create towers that are stronger and more durable than ever before, while also being faster and easier to construct. This has led to a boom in the iron tower industry, as more and more companies are looking to erect these structures. We are proud to be able to say that our company has played a role in this growth, and we look forward to continuing to help the iron tower industry grow in the future.

the fabrication of towers

Laser cutting is a technology that has been used in the fabrication of towers for many years. This technology can help in the production of towers that are more precise and have a higher quality finish. Laser cutting can also help to speed up the production process, as well as improve the accuracy of tower measurements.

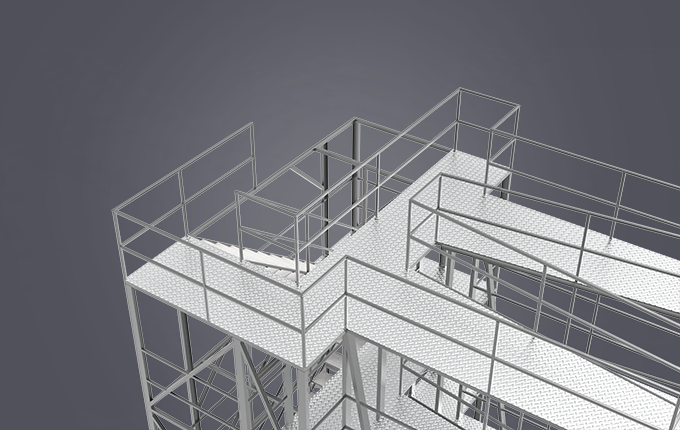

in the cutting of materials.

When it comes to the fabrication of towers, laser cutting can help in the cutting of materials. This is because laser cutting can provide a clean and precise cut, which is essential for ensuring that the tower is stable and safe. Additionally, laser cutting can help to speed up the fabrication process, as it can be used to quickly and easily cut through materials. As such, if you are looking for a way to improve the efficiency of your tower fabrication process, then corte por láser may be the answer.

in the welding of towers

Laser cutting is a method that can be used to cut materials for welding towers. This process is faster and more accurate than traditional methods, and it can help to improve the quality of the welds. In addition, laser cutting can help to improve the efficiency of the welding process, and it can also help to reduce the amount of time and money that is required for the project.