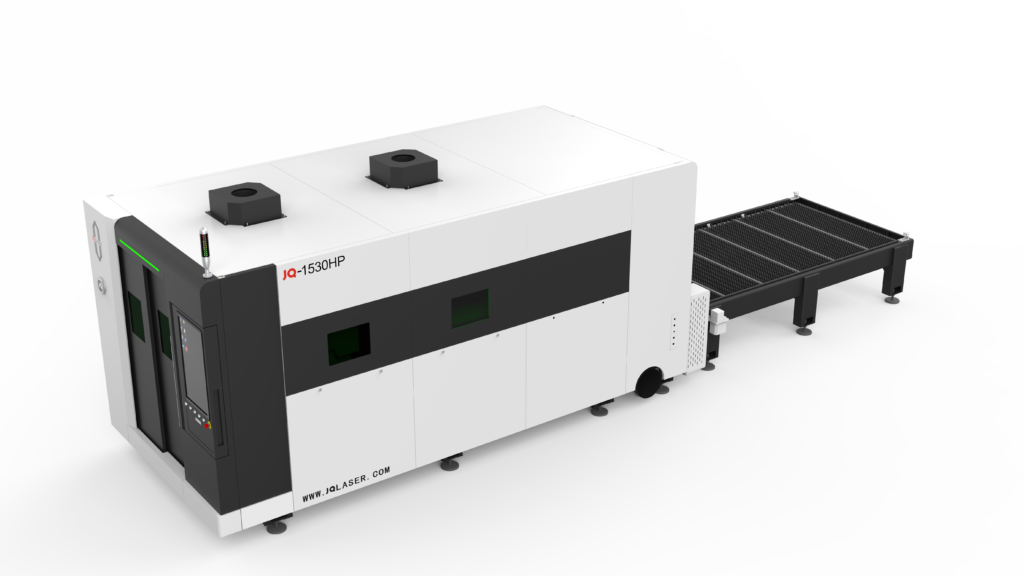

HP SERIES

High cutting speed Working stable High cost-effective

Feature

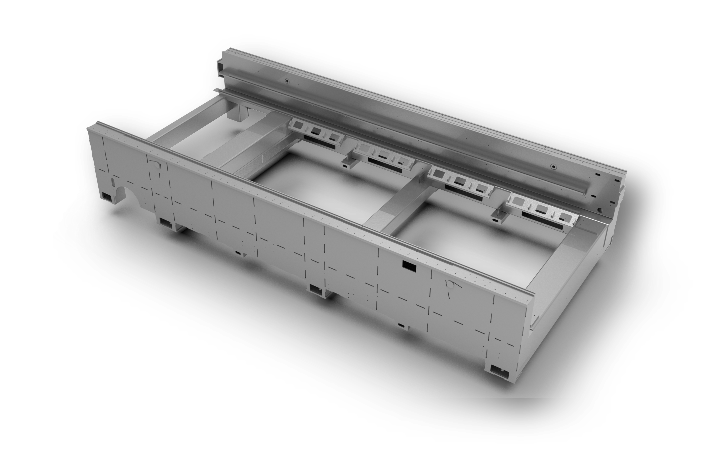

Machine bed

The bed body is made of overall welding, after annealing to eliminate internal stress treatment, after roughing vibration aging and then finishing, thus greatly improving the rigidity and stability of the machine tool, ensuring the accuracy of the machine. Through the CNC system to control its AC servo motor drive, motor drive gear rack to realize the reciprocating movement in the Y direction, to achieve rapid movement. The Y-axis rack and linear guide are made of high precision products, effectively ensuring the precision of transmission; The finite-position switch control at both ends of the trip, together with a hard limit device, effectively ensures the safety of the machine tool movement; The machine is equipped with automatic lubrication device, timed and quantitative lubricating oil to the moving parts of the bed, to ensure that the moving parts operate in good condition, can improve the service life of rails, gears, rack.

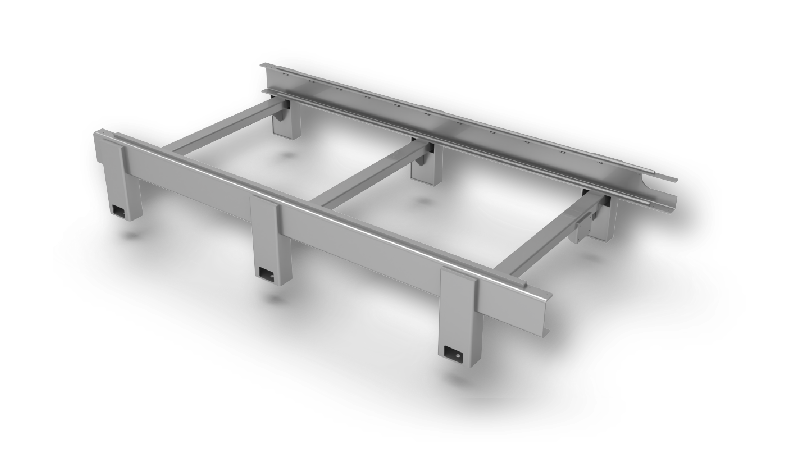

Beam

X-axis frame beams are annealed to eliminate internal stress, after roughing vibration aging then finishing to ensure the rigidity and stability of the laser head moving members. The bed is equipped with high quality linear guide rail, servo motor drive, through high quality gear rack drive, so that the Z-axis skateboard to achieve X-direction reciprocating motion. In the course of motion, the limit switch control stroke limit, at the same time, the two ends of the flexible cushion mechanical limit, to ensure the safety of the system operation. The cross section of the beam is very well subjected to torque performance, the material using aviation aluminum through large tonnage extrusion molding, the internal organization is uniform.

Z-axis

The Z-axis device is mainly to achieve the up and down movement of the laser head. The up and down motion of the laser head is done by CNC system control servo motor, motor drive guide rail screw, drive Z-axis skateboard up and down reciprocating motion. Both the upper and lower ends are controlled by proximity switches to ensure the safety and reliability of the movement. Rail screws are made of high-quality products to ensure the accuracy of the drive.

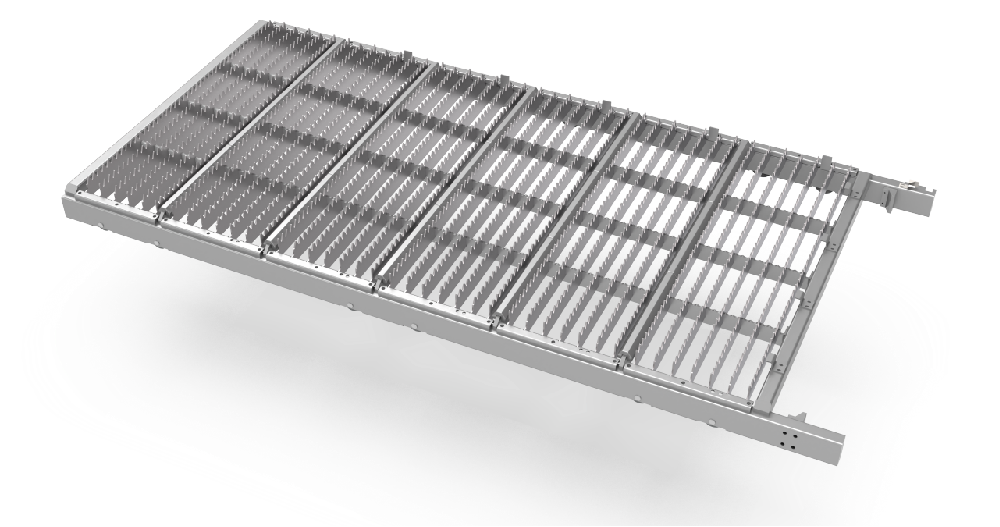

Exchangeable workbench

The work table is mainly composed of support frame, knife frame, sprocket chain, etc., mainly by the sprocket rotation drive chain connection of the upper and lower two layers of knife frame level

Move, the blade frame is mounted with a roller, can ensure the smooth movement of the blade frame.

Fast parallel exchange of front and rear surfaces greatly reduces loading and unloading

Time to improve machining efficiency. Blade, blade frame modular, easy to install and replace. The working platform main body adopts high quality carbon structure steel pipe and

High-quality carbon structure steel plate welding, and manual aging treatment, with better strength and stability, compact structure, easier to replace and disassembly.

Made of high-quality carbon structure steel, high bearing capacity, strong and durable, easy to obtain materials; This compact structure makes it easy to replace and repair knives.

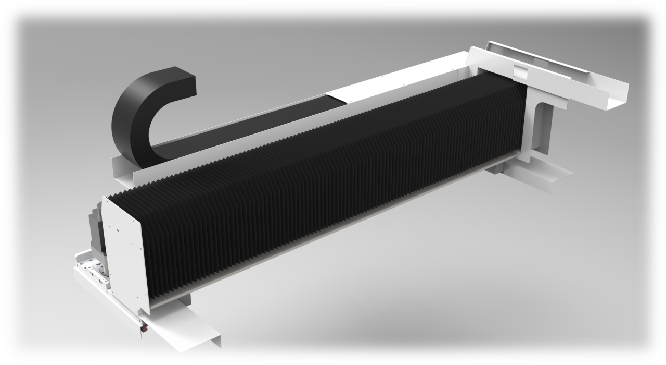

Cover metal sheet

Large surround adopts skeleton design, realizes the closed protection of laser cutting, large surround front sliding door, and set the front and left sides of the laser protective glass, to facilitate the observation of processing; Large encirclement can effectively avoid the occurrence of light leakage, protecting the safety of the operator.

High performance autofocus cutting head

Power rating of 20kW, the product is equipped with QBH, QD, Q +, ADD and other fiber optic interface, can be adapted with a variety of mainstream lasers. Optimized optical configuration and smooth and efficient airflow design significantly improve cutting quality and efficiency.

Autofocusing

Auto-focus, reduce human intervention, auto-focus range of 12 ~ + 10mm, focus accuracy 0.05mm

High adaptability

With QBH, QD, Q +, ADD and other fiber optic interface, can be adapted to a variety of mainstream lasers

High stability fiber laser

High electro-optical conversion efficiency, high efficiency sheet cutting, wide modulation frequency range, maintenance-free operation; Output fiber length can be customized, high resistance.

Related machines

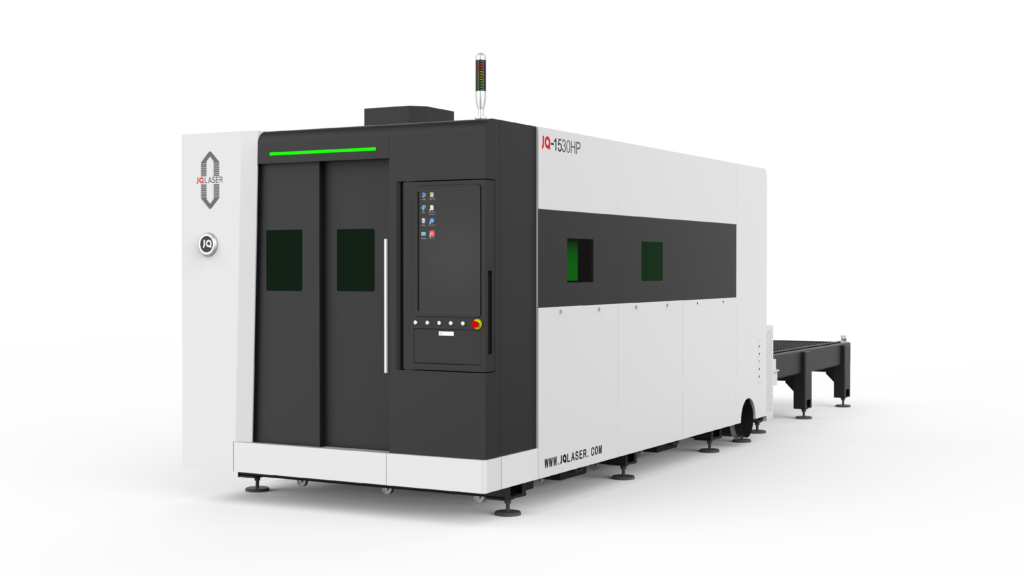

1530HP V2.0

Details: JQ-1530HP V2.0

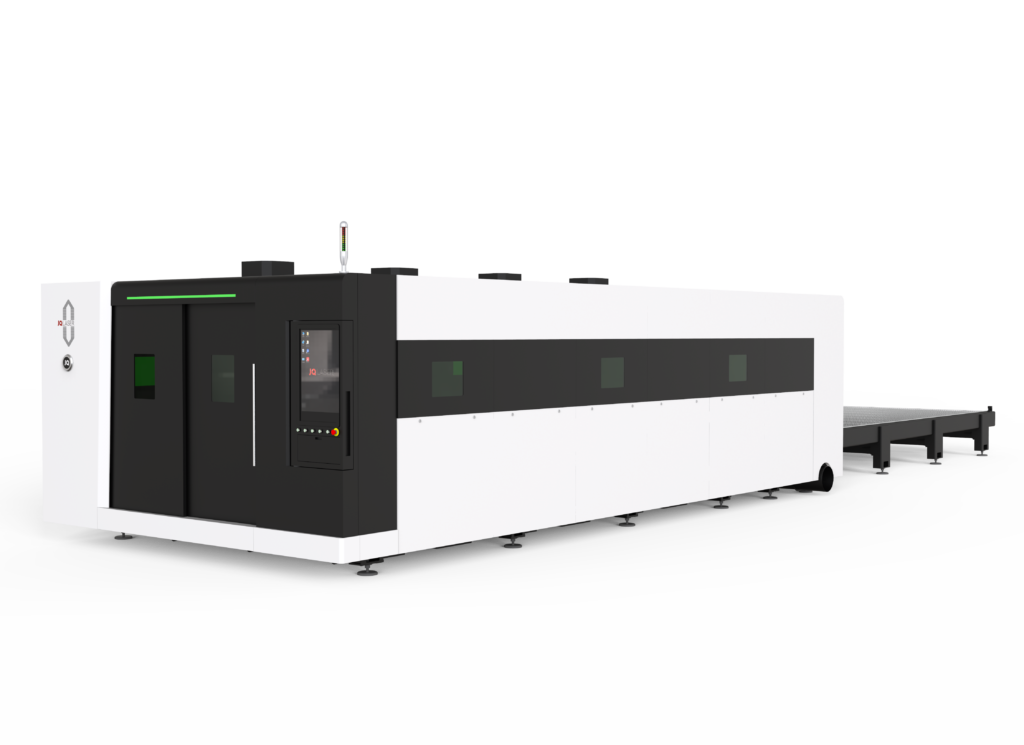

2040HP V2.0

Details: JQ-2040HP V2.0

2560HP V2.0

Details: JQ-2560HP V2.0