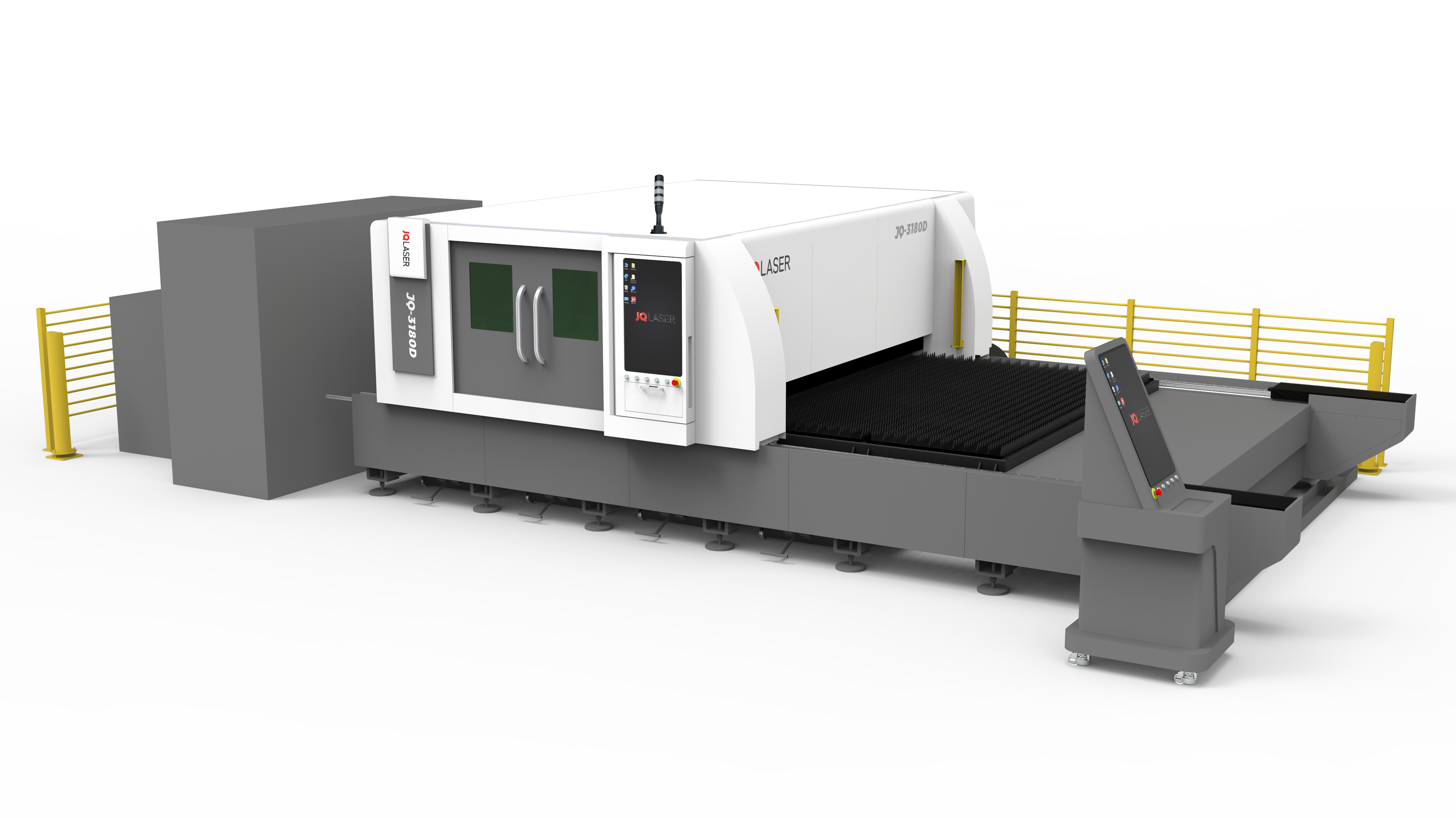

X Y1 Y2 axis compound cutting

- Realize large-format four-axis; can realize three scene cutting, scene 1: small contour range 3X1.25 meters by X, Y2, Z axis cutting inside the beam; scene 2: simple contour larger than 3X1.25 meters by X, Y1, Z axis cutting; scene 3: complex contour larger than 3X1.25 meters by X, Y1, Y2, Z axis cutting;

Aplicación

Efficiency and Modularization

High Efficiency:

The four-axis system optimizes processing time by integrating multiple cutting capabilities into a single machine setup. This reduces the need for multiple machines and minimizes downtime associated with workpiece transfers between different machining operations.

Modular Design: The modular nature of the system allows for easy upgrades and maintenance, facilitating adaptation to various production needs without significant overhauls or downtime.

Structural Optimization

Improved Processing Efficiency: By optimizing the structure of the cutting system, operations can be streamlined. This leads to faster production cycles and reduced waste, which are critical in competitive manufacturing environments.

Facilitated Operation: The intuitive design and control systems simplify operation, making it accessible for operators with varying levels of experience. This contributes to a more efficient workflow and reduces training time.

Document and Information Uniformity

Integrity and Correctness: The system ensures high integrity in process documentation and equipment information. This uniformity is essential for maintaining quality standards across production lines and facilitates compliance with industry regulations.

Process Documentation: Standardized documentation helps in tracking performance metrics and troubleshooting issues effectively, enhancing overall operational reliability.

Recommended Products