- Accueil

- Metal Laser Cutting Machine

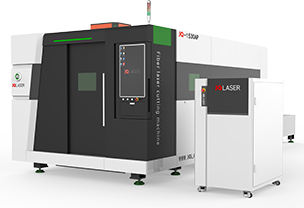

- 1530C Laser Plate And Tube Cutting Machine

1530C Laser Plate And Tube Cutting Machine

If you’re looking for a top-of-the-line laser plate and tube cutting machine, look no further than ours. We produce a 1530C model that is sure to meet your needs and exceed your expectations.

This machine is capable of cutting through thick materials with ease, making it ideal for a variety of applications. Whether you need to cut metal plates or tubes, our machine will get the job done quickly and efficiently.

Plus, our team of experts are always on hand to answer any questions you may have about the machine or its capabilities. So don’t hesitate to contact us today to learn more about what we can do for you.

Technical Parameters

| Working area | 3000*1500mm |

| Pipe cutting specifications | Φ20-Φ220,L=6000 |

| X-axis travel | 2350mm |

| Y-axis travel | 3050mm |

| Z-axis travel | 240mm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Acceleration | 1G |

| Maximum running speed | 100m/min |

| Maximum table loading weight | 900kg |

| Power supply | 380V/50Hz |

Components

machine bed

JQ Laser uses 99% of the industry suppliers apply high-density welded bed, the overall weight of the machine 3500KG, this bed is more stable, solid, not easy to move. Ensure the stable operation of the machine. Cast aluminum beam, more stable, high speed running stability and cutting accuracy

Laser cutting head

JQ Laser 1530E model uses auto-focus Raytools. This laser head has a built-in motor drive unit that drives the focus mirror to automatically change its position within 24mm by a linear mechanism. Users can program continuous focus to complete fast piercing of thick plates and automatic cutting of plates of different thicknesses and materials. The product is equipped with a D30 composite lens set for beam integration, optimized optics and water cooling design allows Raytools to work continuously and consistently at high power for long periods of time.

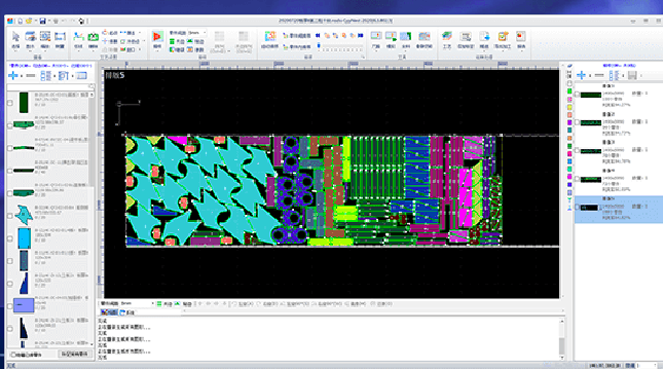

operating system

JQ 1530C uses the FSCUT3000S operating system. the FSCUT3000S medium power laser cutting system is a full-featured open-loop control system introduced specifically for the sheet metal processing industry. It is easy to install, easy to debug, excellent performance and complete solutions.

Smoke filter optional

The fume filter is suitable for collecting and filtering dust from laser cutting carbon steel, stainless steel, copper, aluminum and other metal materials.

1. Special structure design, small body size, low noise operation, can be moved

2. Adopt special aluminum alloy impeller and brand motor, combining negative pressure and flow

3. Set electric control element thermal overload protection, phase failure and phase sequence protection, high safety

4. Standard configuration of Japan Toray polyester fiber laminated cartridge, high efficiency of soot filtration

5. Flame-stopping device at the air inlet, so that sparks can be placed in direct contact with the filter cartridge and damage it.

6. Patented automatic rotating pulse blowback device for better cleaning effect

7. Special air duct and noise reduction design, reduce the noise of the machine outlet

8. Stable operation, low failure rate, continuous operation

Photos of successful installation

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

Leave Message And Get The Answer

In order to improve the user experience and improve our production technology, JQ laser has been collecting real machinery handling questions and comments from the market, which we will analyze and provide answers to, and we will also adopt the favorable production ideas.