Will fabricating machinery from China be excluded from new tariffs?

The Biden administration has proposed significant tariff increases on Chinese imports, but in a surprising move, it’s considering excluding certain manufacturing equipment, including fabricating machinery, from these new tariffs. This potential exclusion could have major implications for U.S. metal fabricators and the broader manufacturing sector.President Biden’s administration is moving forward with tariff increases on imported […]

How Laser and TIG Welding Harmonize in Today’s Job Shops

In the modern job shop, laser and TIG welding coexist as complementary techniques, each offering unique advantages that cater to different needs within the fabrication process. The integration of these two methods allows job shops to maximize efficiency, precision, and versatility, addressing a wide range of welding requirements.Laser welding is renowned for its precision and […]

Laser Welding vs. TIG Welding

Laser welding and TIG (Tungsten Inert Gas) welding are two prominent techniques used in the metalworking industry, each with its own set of advantages and applications. Understanding the differences between these methods can help manufacturers choose the right technique for their specific needs.Laser welding is a high-precision technique that uses a laser beam to join […]

Sheet metal cutting Sheet metal cutting HP series upgrade V2.0

HP SERIES Feature Machine bed The bed body is made of overall welding, after annealing to eliminate internal stress treatment, after roughing vibration aging and then finishing, thus greatly improving the rigidity and stability of the machine tool, ensuring the accuracy of the machine. Through the CNC system to control its AC servo motor drive, […]

The Crucial Role of Laser Cutting Safety: Protecting Your Workforce and Business

The Importance of Laser Cutting Safety Laser cutting is a highly efficient and versatile technology used in various industries, from manufacturing to art. However, the importance of laser cutting safety cannot be overstated. Ensuring a safe working environment is crucial to prevent accidents and health hazards associated with laser operations.Laser cutting involves high-powered lasers that […]

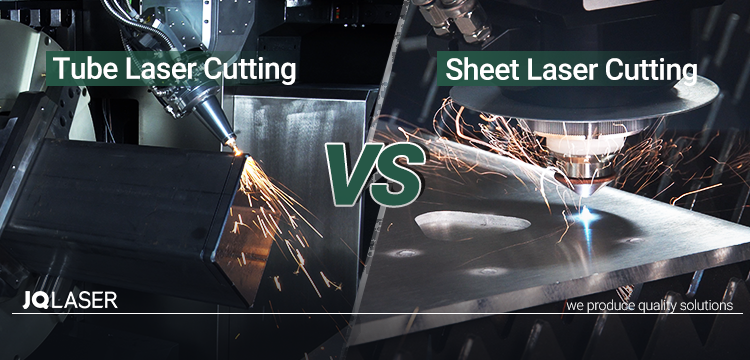

Why Tube Laser and Sheet Metal Cutting Speeds Differ

The speed difference between tube laser cutting and sheet metal cutting is a topic of significant interest in the manufacturing industry. While both technologies utilize laser cutting, their applications and efficiencies differ due to the inherent complexities of the materials and shapes they handle. Complexity of Tubular Workpieces One of the primary reasons tube lasers […]

New Product Metal Sheet Cutting JQ 3180D

Background With the increasing replacement of plasma equipment by high-power flatbed cutting machines in recent years, the demand for high-power and high-speed cutting of medium and thick plates has also emerged. At the same time, in the sub-sectors such as engineering machinery, boilers, agricultural machinery, etc., the demand for high-speed cutting of large-format medium and […]

The Revolutionary Sheet Metal Laser Cutting Process

Sheet Metal Laser Cutting Process Sheet metal laser cutting is a thermal cutting process that uses highly concentrated beams of light (lasers) to melt or vaporize materials until the desired shape is achieved. This technique is renowned for its precision, speed, and versatility, making it a preferred method for cutting various metals, alloys, and even […]

Laser welding process and principle

Welding Processes and Principles 1.1 Definition of Welding Welding is the process of joining two or more materials, either similar or different, by creating atomic or molecular bonds through heating, applying pressure, or a combination of both. The methods used to facilitate these bonds include heating, pressing, or both simultaneously. 1.2 Classification of Metal Welding […]

Laser cleaning technology principle and application progress

With the continuous development of high-end fields such as aerospace, petrochemical, high-speed rail, weapons, and nuclear power in China, the environments in which various equipment components are located have also changed accordingly, with increasingly high requirements for the performance of metal material components. To improve overall equipment performance and extend the service life of parts, […]