Introduction: How to Use a Laser Cutter

If you’ve ever wanted to work with laser cutters, this article is for you! You’ll learn how to use a laser cutter, what materials work best, and how to troubleshoot any issues you may have. With a little practice, you’ll be able to create beautiful projects with ease.

What is a laser cutter?

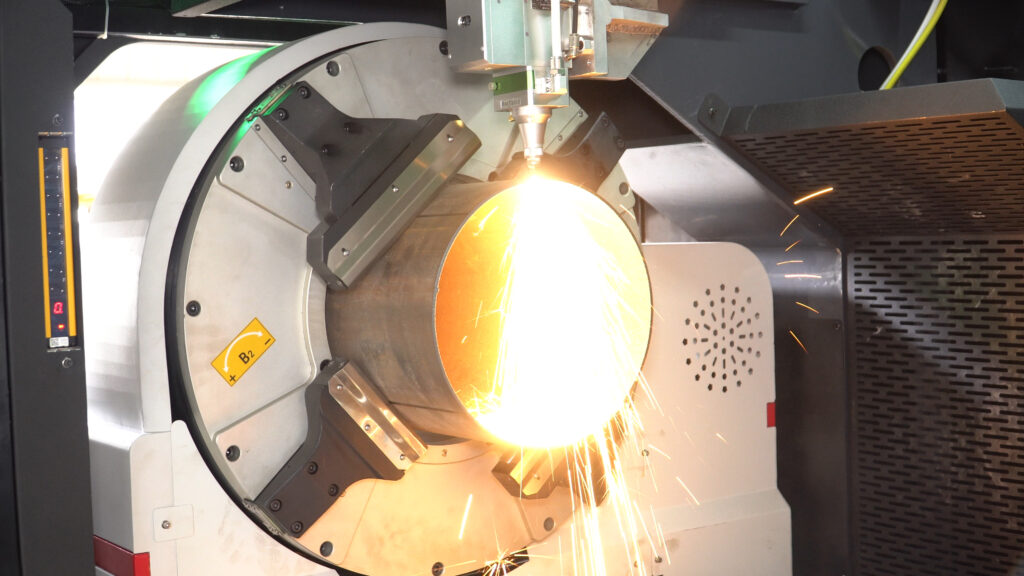

A laser cutter is a device that uses a laser to cut materials. It is commonly used to cut metal, but can also be used to cut other materials, such as plastics and wood.

Laser cutters work by focusing the laser beam on the material to be cut. The high-powered laser beam melts, vaporizes, or burns through the material, depending on the power of the laser and the material being cut.

Laser cutters are often used in manufacturing and prototyping applications because they offer a fast and accurate way to cut materials. They are also relatively easy to use, which makes them a popular choice for small businesses and hobbyists.

How does a laser cutter work?

Laser cutting is a technology that uses a laser to cut materials, and it is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser at the material to be cut. The material is heated to its melting point by the laser and is then blown away by a stream of gas.

Laser cutting is a very precise process and can be used to cut complex shapes with tight tolerances. It can also be used to cut through thick materials, such as metals and plastics. Laser cutting is much faster than traditional methods such as machining or grinding, and it produces little or no burr on the edges of the cuts.

What can you do with a laser cutter?

A laser cutter is a versatile tool that can be used for a variety of purposes. Here are just a few of the things you can do with a laser cutter:

1. Cut out shapes and designs from paper, wood, metal or other materials.

2. Engrave text or images onto surfaces.

3. Create three-dimensional models and sculptures.

4. Decorate objects with intricate patterns or designs.

The possibilities are endless! So if you’re looking for a versatile tool to help you create beautiful things, consider investing in a laser cutter.

What materials can be cut or engraved with a laser?

Wood

Wood is one of the most commonly cut and engraved materials, due to its versatility and Laser systems are able to process a wide variety of wood types, including both hardwoods and softwoods.

Hardwoods, such as oak, maple, and cherry, can be easily cut and engraved with a laser. These woods are also very strong and durable, making them ideal for projects that require a high level of precision.

Softwoods, such as pine and cedar, can also be cut and engraved with a laser. However, these woods are not as strong or durable as hardwoods. They are often used for projects that require less precision, such as signs or decorations.

Paper

Paper can be cut or engraved with great precision and detail using a laser. Other materials that can be cut or engraved with a laser include wood, plastic, metal, and glass.

Metal

Meanwhile, it works especially well on metal. Metal is a very strong and durable material, so it can withstand the high heat and intense light that a laser produces. This makes it possible to create very intricate designs and patterns on metal surfaces. Laser cutting and engraving is a very precise process, so it can be used to create detailed images and text. It is also possible to cut metal into different shapes using a laser. This makes it an ideal material for creating unique jewelry, artwork, or other decorative items.

Plastic and glass

Acrylic and glass are two of the most popular materials to cut with a laser. They both have a high melting point, which means that the laser beam can pass through without damaging the material. Leather and fabric are also popular choices for laser cutting, as they can be easily engraved with intricate designs. Rubber is another great option for those who want to create custom stamps or seals.

Things you should know before operating a laser cutting machine

Know the Machine Safety

First, make sure you know the machine. Get familiar with the controls and how it works. Second, always wear safety equipment. This includes eye protection, gloves, and a respirator. Third, be aware of your surroundings. Keep flammable materials away from the machine and know where the emergency stop button is located. Fourth, make sure the area is well-ventilated. lasers produce harmful fumes so it’s important to have good ventilation. Fifth, follow the manufacturer’s instructions. Don’t try to change anything or operate the machine outside of its intended use. Sixth, keep an eye on the material you’re cutting. If it starts to smoke or catch fire, stop immediately and take proper precautions. Seventh, never look directly at the laser beam. It can damage your eyesight permanently.

Know the Hardware

Familiarize yourself with the different parts of the machine and how they work together. Pay close attention to the laser beam path and understand how it works. It’s also important to know how to adjust the focus of the laser beam.

The Software

Three main types of files can be used with this software: vector files, bitmap files, and JPEG files. Vector files are the most commonly used type of file for laser cutting because they’re easy to edit and resize. Bitmap files are also common, but they’re not as easy to edit as vector files. JPEG files are usually only used for photos or images that will be printed on the finished product.

Power and Speed Settings

The power setting on a laser cutter determines how much energy is used to cut through the material. The higher the power setting, the more energy is used. The speed setting controls how fast the laser beam moves across the material. A higher speed setting will result in a faster cut, but it may not be as precise as a lower speed setting.

To get the best results from your laser cutter, it’s important to experiment with different power and speed settings. Start with lower settings and gradually increase them until you find the perfect combination for your project.

Frequency Settings

The frequency setting on a laser cutter controls how often the laser beam fires within a given period of time. A lower frequency will mean that the beam will fire less often, while a higher frequency will result in the opposite.

Generally speaking, you’ll want to start with a lower frequency and then gradually increase it until you find the sweet spot for your particular material. This trial-and-error process is essential to getting good results with your laser cutter.

Once you’ve found the right frequency setting, make sure to write it down so you can replicate it in future sessions. With this bit of knowledge under your belt, you’re well on your way to becoming a laser cutting pro!

Placing Materials

Another important thing to keep in mind is the size of the material you’re working with. Laser cutting machines are designed to cut through materials of a certain thickness – so if your material is too thick, it could damage the machine. Conversely, if your material is too thin, it might not cut all the way through and you’ll end up with an unfinished project.

Focusing the Laser Cutter

When you’re operating a laser cutter, it’s important to make sure that the beam is properly focused. If the beam is not properly focused, it can cause problems with the cut.

There are two ways to focus the laser cutter: manual and automatic. With manual focusing, you’ll need to adjust the focus manually. This can be done by moving the lens up or down. With automatic focusing, the laser cutter will automatically adjust the focus for you. Either way, it’s important to make sure that the beam is properly focused before starting your project.

Test Cut

Before operating a laser cutting machine. For starters, always test cut on a scrap piece of material before cutting your final project. This will help you adjust the settings and ensure that you’re getting a clean cut.

Start to Work

Cautions When Using Laser Cutting Machine

When making use of a laser cutting machine there are certain cautions you need to take in order to avoid any accidents. Here are four main points to keep in mind when using a laser cutter:

1. Make sure you have proper ventilation in the room where the machine is being used. This is because when the laser is cutting, it produces harmful fumes that can be dangerous to breathe in. Our equipment has a smoke extraction system that will reduce injuries to people and reduce safety hazards.

2. Always wear protective gear when operating the machine, such as gloves and safety glasses. This will help to protect your hands and eyes from the strong laser beam.

3. Be very careful when moving or adjusting the laser cutter, as it is a very delicate piece of equipment. Any sudden movement could damage the machine or cause it to malfunction.

4. Always be aware of the laser beam. The laser is extremely strong and very hot, so avoid touching it or being near it when it is turned on. If the beam does touch you, immediately turn off the machine.

5. Never operate the machine if it is not properly assembled. Always check that the laser and safety covers are in place before operation.

6. Make sure that all cables are properly connected and avoid any entanglement.

7. Never leave the machine unattended while it is turned on.

8. Always turn off the machine before removing or adding any media.

9. Always make sure that the tray is properly loaded and closed before operation.

10. Never touch the lens with your fingers, as it could permanently damage the lens and affect the quality of your scan.

11. Never attempt to remove the protective cover from the lens.

12. Always unplug the machine when not in use and before cleaning or performing any maintenance.

Care and Maintenance of Laser cutting machine

Laser cutting machines are an impressive tool that can be used for a variety of projects. While they may be expensive, they are worth the investment because of the many benefits they offer. In order to keep your machine in good condition, it is important to follow a few simple care and maintenance tips.

First, always read the owner’s manual that comes with your machine. This will give you specific instructions on how to care for and maintain your machine. Second, make sure to keep the area around your machine clean and free of debris. This will help prevent accidents and damage to the machine. Third, regularly inspect your machine for any wear or tear. If you notice any problems, be sure to fix them immediately.

By following these simple tips, you can help ensure that your laser cutting machine lasts for many years to come.

Conclusion

In conclusion, operating a laser cutting machine is not as difficult as it may seem. With strict training and practice, most workers can do it. By following the tips in this article, you will be able to cut through materials quickly and efficiently.