- Accueil

- Tube Laser Cutting Machine

- T1 Pipe Laser Cutting Machine

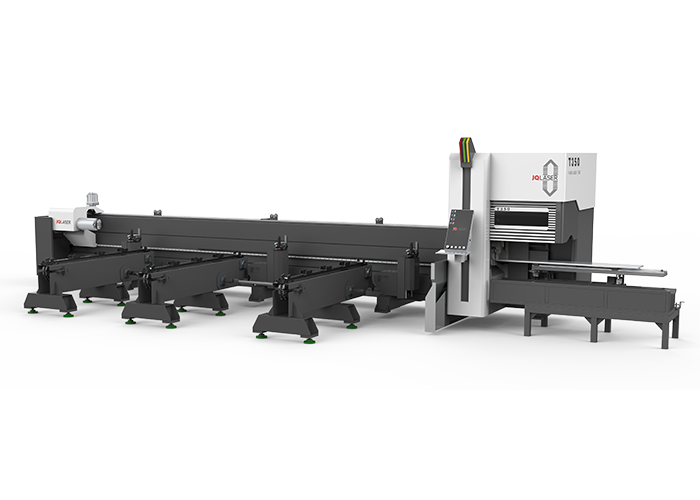

T1 Pipe Laser Cutting Machine

If you’re looking for a high-quality T1 pipe laser cutting machine, look no further than us. We’re confident in our ability to provide a top-notch product that will meet your needs and exceed your expectations.

Here at our company, we take pride in our workmanship and attention to detail. We only use the highest quality materials to construct our T1 pipe laser cutting machines. And we stand behind our products 100%.

So if you’re in the market for a top-of-the-line T1 pipe laser cutting machine, give us a call today. We’ll be happy to answer any questions you have and provide you with a free quote.

Technical Parameters

| Maximum cutting length | ≤7000mm |

| Maximum weight for each tube | 200kg |

| Cutting diameter | 15-165mm |

| Rotary speed | 100rpm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Minimum tailing | ≥90mm |

| Maximum running speed | 60m/min |

| Power supply | 380V/50Hz |

Components

Fonctionnalité

The main use and application scope of the product

It is mainly used for round, square, rectangular, elliptical and waist round pipes of common carbon steel and stainless steel materials, cutting workpiece size Φ15-Φ165mm (workpiece external circle), feeding maximum length ≤7000mm.

The main composition of the product

The main components of T1 series laser pipe cutting machine are: main machine tool, chain type semi-automatic feeding mechanism, control system, laser, water chiller, extractor fan, etc.

Machine tool host part

The main part of the machine is the main component of the whole laser pipe cutting machine, the cutting function and cutting accuracy of the laser pipe cutting machine are realized by the main part, the main part is composed of bed and auxiliary support, X-axis gantry, chuck part, Z-axis device, front receiving device, auxiliary system (protective outer cover, air and water circuit), operation table and other parts.

Semi-automatic feeding mechanism

The semi-automatic feeding mechanism can realize the semi-automatic feeding function of round pipe, square pipe, rectangular pipe and profile, and the pipe needs to be placed in the storage part manually.

Electrical control part

Laser pipe cutting machine electrical control system is an important part of ensuring the running trajectory of various graphics, the general electrical control system is mainly composed of CNC system and low-voltage electrical system.

The machine tool CNC system configuration high-performance CNC system, the system is based on windows operating platform, stable and reliable operation, containing 64-bit microprocessor; the system has a fast interpolation operation speed, easy to operate, good dynamic performance, strong load capacity and other characteristics.

Low-voltage electrical system

The low-voltage electrical system is located in the electric control cabinet, which is the interface part of the electrical control of the whole machine. All the original components of the electrical system are made by famous manufacturers at home and abroad to ensure that the machine is stable, reliable and responsive in operation. The drive motor is AC servo motor, AC servo motor used to drive the X-axis, Y-axis, AW (synchronous rotation) axis of the machine tool, characterized by good acceleration performance, fast response speed, W, Y-axis maximum positioning speed of up to 100m/min; machine tool Z-axis for the feed axis, using AC servo motor (with holding brake) for driving: that is, Z-axis cutting head, characterized by good dynamic response characteristics, both with the control and NC control.

Auxiliary peripheral equipment

Including water chiller, cold air system, exhaust system, etc.

Bed and auxiliary support part

The bed adopts side-hanging structure and stacked welded one-piece bed, which is treated by annealing to eliminate internal stress, and then finish machining after rough machining with vibration aging, thus greatly improving the rigidity and stability of the machine tool and ensuring the accuracy of the machine tool. The Y-axis rack and linear guide are made of high precision products, which effectively ensure the accuracy of the transmission; both ends of the stroke are controlled by limit switches and equipped with hard limit devices, which effectively ensure the safety of the machine movement; the machine is equipped with automatic lubrication device, which adds lubricant to the moving parts of the bed at regular and quantitative intervals. The machine is equipped with automatic lubrication device to add lubricating oil to the moving parts of the bed regularly and quantitatively to ensure that the moving parts operate in good condition, which can improve the service life of guide rails, gears and rack.

There are 3 groups of follow-along support mechanism on the bed, each group of support is controlled by independent servo motor to lift, mainly to follow-along with the excessive deformation of cutting longer pipe (pipe with smaller diameter). When the rear chuck moves to the corresponding position, the auxiliary supports can be lowered for avoidance.

X-axis device and chuck part

The cross beam of X-axis device adopts gantry type structure, which is made of square tube and steel plate combination welded, annealed to eliminate internal stress, rough machining, vibration aging and then finishing to ensure the rigidity and stability of the moving parts of the laser head. The gantry components are fixed on the bed, and the X-axis adopts servo motor-driven linear module drive to realize the reciprocating motion of the slide in X direction. In the process of movement, the limit switch controls the stroke for limit to ensure the safety of system operation.

The chuck is divided into 2 pneumatic full-stroke chucks, front and rear, both of which can move in Y direction. The rear chuck is responsible for clamping the feeding pipe, and the front chuck is installed at the end of the bed for clamping the material used. The front and rear chucks are driven by servo motor respectively, which can achieve synchronous rotation.

With the double chucks clamping together, short tail material can be cut and the last workpiece needs to be picked up manually.

Z-axis device

The Z-axis device is mainly to realize the up and down movement of the laser head. The up and down movement of the laser head is controlled by the CNC system with a servo motor, which drives the linear module and drives the Z-axis slide plate to reciprocate up and down to complete the movement. The upper and lower ends are controlled by proximity switches to ensure the safety and reliability of the movement. The linear modules are made of high quality products to ensure the accuracy of transmission.

The Z-axis can be used as a CNC axis for its individual interpolation motion, while it can be linked with X and Y axes, and can be switched to the follower control to meet the needs of different situations. Since the Z-axis follower is also controlled by the CNC system, the accuracy of the follower is high and the stability is good, thus ensuring the quality of the cut.

After the capacitive sensor in the Z-axis device detects the distance from the nozzle to the surface of the plate, the signal is fed back to the control system, and then the control system controls the Z-axis motor to drive the cutting head up and down, thus controlling the constant distance between the nozzle and the plate and effectively ensuring the cutting quality. The cutting head can adjust the focus automatically or manually, and the position of the focus can be adjusted according to the material and thickness of the cutting material, thus obtaining a good cutting section.

Front pick-up device

The front pick-up device consists of a cylinder-controlled support plate to hold the pipe when it is cut long and to prevent it from sagging.

When the workpiece is being cut, the lifting support cylinder holds the support plate to support the pipe and prevent it from sagging. When the workpiece is finished cutting, the rising support cylinder retracts completely and the workpiece falls onto the drop plate and slides down to the material storage area. The cylinder action is automatically controlled by the system.

Chain type semi-automatic feeding device

Standardly equipped with 3 groups of chain feeding devices, which can realize semi-automatic feeding of round pipe, square pipe, rectangular pipe and profile, and need manual swinging of material.

Electrical control system

T1 series CNC laser pipe cutting machine electrical control system is mainly composed of Patrons CNC system, servo system and low voltage electrical system. This laser cutting machine is equipped with high performance Pakchu CNC system, which is a WINDOWS-based PC CNC system with the characteristics of fast interpolation operation and convenient operation; the servo system is a servo motor and driver, which is stable and reliable, with good dynamic performance, strong ability to carry load and convenient operation. The machine operation soft keys can have different functions in different operation modes, thus reducing the operation buttons and simplifying the operation panel. The operation functions are displayed by menus in various ways, making the operation intuitive.

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

Leave Message And Get The Answer

In order to improve the user experience and improve our production technology, JQ laser has been collecting real machinery handling questions and comments from the market, which we will analyze and provide answers to, and we will also adopt the favorable production ideas.