Precision pipes are an essential component of various industries such as automotive, aerospace, and construction. The production of these pipes requires high accuracy and precision. Laser cutting has revolutionized the manufacturing of precision pipes since it offers superior precision, efficiency, and versatility. This article discusses the importance of laser cutting in precision pipe manufacturing by exploring its evolution, advantages, and future prospects.

Cutting-Edge Techniques: The Evolution of Laser Cutting in Pipe Manufacturing

The use of laser cutting in precision pipe manufacturing has undergone significant evolution over the years. Initially, découpe au laser was used for low-volume projects since it was expensive and time-consuming. However, the development of advanced laser cutting machines has reduced the cost and improved the efficiency, making it more accessible to higher-volume production lines. The latest advancements have enabled the cutting of complex shapes and patterns with high accuracy and speed.

The Art of Mastering Laser Cutting

Laser Cutting Equipment

Mastering laser cutting begins with the right equipment. High-powered lasers, precision optics, and advanced control systems are key components of a laser cutting setup.

Computer-Aided Design (CAD)

CAD software plays a pivotal role in the precision of laser cutting. Engineers and designers use CAD to create intricate designs and patterns that are translated into precise cuts by the laser.

Material Selection

Choosing the right material is crucial in laser cutting. Different materials respond differently to laser beams, and selecting the appropriate one ensures clean and accurate cuts.

Precision in Motion

The precision of laser cutting is not limited to stationary objects. CNC (Computer Numerical Control) systems enable laser cutting machines to move with incredible accuracy, even in complex patterns.

The Advantages of Laser Cutting in Precision Pipe Production

Laser cutting has several advantages over traditional cutting methods such as sawing and drilling, including:

- Superior precision and accuracy

- High speed and efficiency

- Reduced material waste

- Versatile cutting capabilities

- Reduced need for secondary operations

For precision pipe manufacturing, these advantages translate into enhanced product quality, reduced production time, and increased cost-effectiveness.

Maximizing Efficiency: Laser Cutting’s Impact on Precision Pipe Manufacturing

Efficiency is a critical factor in precision pipe manufacturing since it directly impacts production time, product capacity, and cost. Laser cutting is an efficient cutting method due to its high accuracy and speed, which reduces the need for secondary operations that take time and resources. Laser cutting also allows for the use of multiple cutting heads, which enables the simultaneous cutting of multiple pipes. This technology makes it possible to produce more products in a shorter time, enhancing the overall efficiency of the production line.

Accuracy is Key: How Laser Cutting Ensures Precision in Pipe Production

Precision is a fundamental requirement in precision pipe manufacturing, and découpe au laser is the ideal method of accomplishing this feat. Laser cutting is incredibly accurate, making it possible to cut pipes with high tolerances and intricate designs. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software ensures that the patterns are precise, further enhancing the accuracy of the cutting process.

Going Beyond the Limits: The Versatility of Laser Cutting in Precision Pipe Manufacturing

Laser cutting is incredibly versatile, making it ideal for cutting pipes of different materials and thicknesses. The introduction of different laser types, such as fiber and CO2 lasers, has made it possible to cut materials such as stainless steel, aluminum, and titanium, among others. Additionally, the ability to cut multiple shapes and designs has made it possible to produce customized and specialized precision pipes for specific industries.

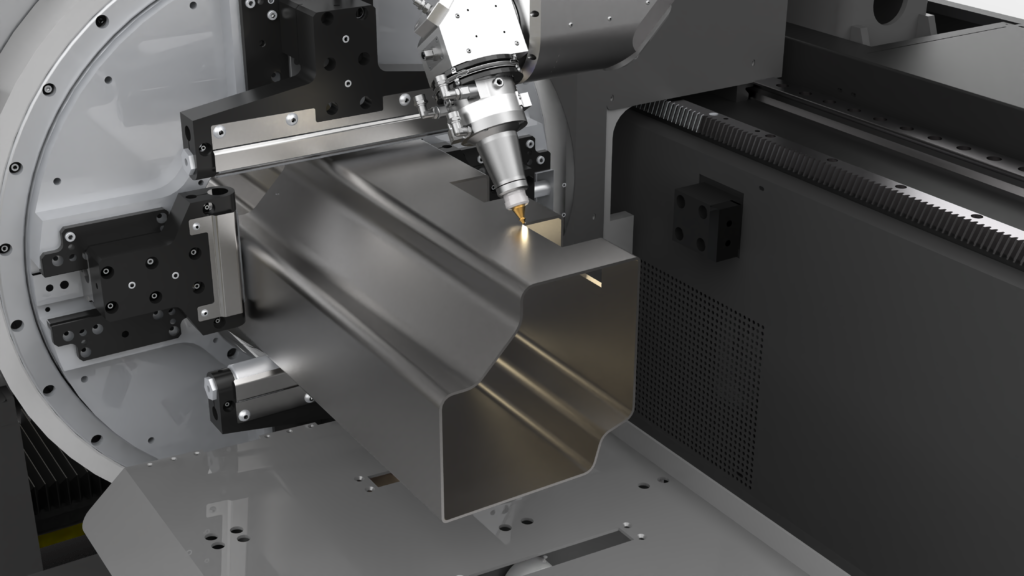

Perfection in Motion: The Role of Laser Cutting Machines in Precision Pipe Production

Laser cutting machines play a critical role in precision pipe production since they determine the efficiency and quality of the cutting process. The use of advanced laser cutting machines makes it possible to cut pipes of different diameters and thicknesses with high accuracy and speed. Additionally, the use of automated loading and unloading systems simplifies the cutting process, reducing the need for manual intervention.

Creating Intricate Designs: The Benefits of Laser Cutting for Custom and Specialized Precision Pipes

Laser cutting is ideal for creating customized and specialized precision pipes due to its ability to cut complex patterns with high accuracy. This technology enables the production of pipes with intricate designs, which are essential in certain industries, such as aerospace and automotive. The ability to customize and specialize pipes to meet specific industry requirements significantly enhances the overall quality of the product.

Innovation at its Finest: The Future of Laser Cutting in Precision Pipe Manufacturing

Les future of laser cutting in precision pipe manufacturing is bright, with significant prospects for innovation and advancement. The introduction of 3D laser cutting technology is set to revolutionize the manufacturing of precision pipes by enabling the production of more complex shapes and designs. Additionally, the integration of IoT technology and artificial intelligence in laser cutting machines is set to enhance the efficiency and productivity of the cutting process.

Achieving Perfection: How Laser Cutting is Revolutionizing the Precision Pipe Industry

Laser cutting has transformed the precision pipe industry by enhancing the quality, efficiency, and versatility of the production process. Its superior accuracy, speed, and versatility make it the ideal cutting method for producing complex designs and shapes. The future prospects of laser cutting in precision pipe manufacturing highlight its potential to revolutionize the industry further by introducing new and innovative cutting technologies.