Laser cutting machine research and development (R&D) systems play a crucial role in advancing manufacturing technology and capabilities. These systems are responsible for innovating and improving laser cutting machines, which are essential tools in various industries for precise and efficient material cutting.R&D in laser cutting technology focuses on enhancing machine performance, accuracy, speed, and versatility. It involves developing new laser sources, improving beam quality, optimizing cutting parameters, and creating more sophisticated control systems. The continuous advancement in this field enables manufacturers to produce more complex parts, work with a wider range of materials, and increase overall productivity.

| Aspect | Détails |

|---|---|

| Key Focus Areas | Laser source development, beam quality improvement, cutting parameter optimization, control system enhancement |

| Industries Impacted | Automotive, aerospace, electronics, medical devices, consumer goods |

| Benefits | Increased precision, higher cutting speeds, improved material versatility, reduced operational costs |

| Major Players | Trumpf, Bystronic, Mazak, Amada, IPG Photonics |

| Recent Innovations | Fiber laser technology, automated material handling systems, AI-driven process optimization |

| Reference | Laser Cutting Machine Market Report |

Driving Technological Advancements

Laser cutting machine R&D systems are at the forefront of driving technological advancements in the manufacturing sector. These systems are responsible for developing cutting-edge technologies that push the boundaries of what’s possible in material processing. For instance, recent R&D efforts have led to the development of ultra-high-power fiber lasers capable of cutting thick metal plates at unprecedented speeds.One of the primary focuses of laser cutting machine R&D is improving beam quality. Higher beam quality translates to more precise cuts, cleaner edges, and the ability to work with more challenging materials. Researchers are constantly working on new ways to shape and control laser beams, leading to innovations like beam shaping optics that can dynamically adjust the beam profile during cutting.

Enhancing Machine Performance and Efficiency

R&D systems play a crucial role in enhancing the overall performance and efficiency of laser cutting machines. This includes developing more powerful and energy-efficient laser sources, improving motion control systems for faster and more accurate positioning, and creating advanced software algorithms for optimizing cutting paths.One significant area of research is in reducing heat-affected zones (HAZ) during cutting. By minimizing HAZ, manufacturers can produce parts with better mechanical properties and less distortion. R&D efforts in this area have led to the development of ultra-short pulse lasers that can ablate material with minimal heat transfer.

Expanding Material Processing Capabilities

Laser cutting machine R&D systems are continually working to expand the range of materials that can be processed effectively. This includes developing new techniques for cutting challenging materials like composites, ceramics, and multi-layer materials. For example, recent advancements have made it possible to cut brittle materials like glass with unprecedented precision using specialized laser sources and cutting techniques.Research is also being conducted on improving the cutting of reflective materials like copper and aluminum, which have traditionally been challenging for laser cutting. New laser wavelengths and beam delivery systems are being developed to address these challenges, opening up new possibilities for industries that work with these materials.

Integration of Artificial Intelligence and Machine Learning

One of the most exciting areas of laser cutting machine R&D is the integration of artificial intelligence (AI) and machine learning (ML) technologies. These advanced systems are being used to optimize cutting parameters in real-time, predict and prevent machine failures, and even automate the entire cutting process from design to finished part.AI-driven systems can analyze vast amounts of data from sensors embedded in the laser cutting machine to make instant adjustments to cutting parameters. This results in improved cut quality, reduced waste, and increased overall efficiency. Machine learning algorithms are also being used to develop predictive maintenance systems that can anticipate when a machine will need servicing, reducing downtime and maintenance costs.

Addressing Environmental Concerns

Laser cutting machine R&D systems are also focusing on making the technology more environmentally friendly. This includes developing more energy-efficient lasers, reducing waste material, and finding ways to recycle or reuse cutting by-products. For instance, research is being conducted on closed-loop systems that can capture and filter fumes and particulates generated during cutting, making the process cleaner and safer.Another area of focus is on reducing the power consumption of laser cutting machines. This involves not only improving the efficiency of the laser source itself but also optimizing all other components of the machine, from cooling systems to motion control.

Advancing Automation and Industry 4.0 Integration

R&D systems are playing a crucial role in advancing the automation capabilities of laser cutting machines and their integration into Industry 4.0 frameworks. This includes developing sophisticated robotic material handling systems, creating seamless interfaces with other manufacturing processes, and enabling real-time data exchange between machines and enterprise systems.Research is also being conducted on developing more flexible and modular laser cutting systems that can be easily reconfigured for different production needs. This adaptability is crucial for manufacturers looking to respond quickly to changing market demands.

Improving Safety Features

Safety is a paramount concern in laser cutting operations, and R&D systems are continually working to improve safety features. This includes developing more sophisticated laser containment systems, improving emergency shut-off mechanisms, and creating better fume extraction systems.Research is also being conducted on developing new types of protective equipment for operators, including advanced eye protection that can adapt to different laser wavelengths and power levels.

Enhancing User Interface and Ease of Use

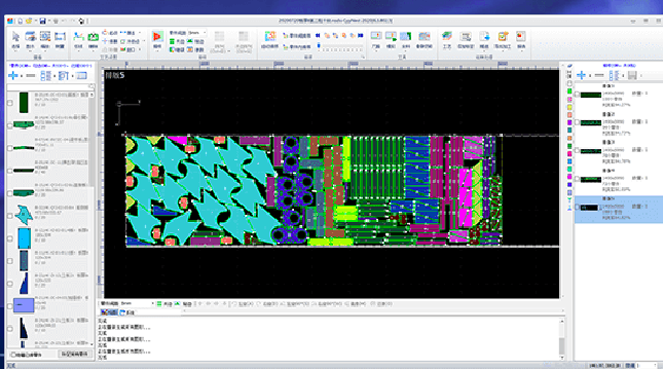

Making laser cutting machines more user-friendly is another important focus of R&D systems. This involves developing more intuitive control interfaces, creating better visualization tools for setting up and monitoring cutting jobs, and implementing features that can guide less experienced operators through complex tasks.Research is also being conducted on developing augmented reality (AR) interfaces that can overlay cutting information directly onto the workpiece, making it easier for operators to set up and monitor jobs.

Addressing Challenges in Micro and Nano-scale Cutting

As industries demand ever-smaller and more precise components, laser cutting machine R&D systems are focusing on developing technologies for micro and nano-scale cutting. This involves overcoming challenges related to beam focusing, material handling, and process control at these extremely small scales.Research in this area is leading to the development of new types of ultra-precise laser cutting machines that can produce features measured in microns or even nanometers. These advancements are particularly important for industries like electronics and medical device manufacturing.In conclusion, laser cutting machine R&D systems are vital for driving innovation in manufacturing technology. By continually pushing the boundaries of what’s possible, these systems ensure that laser cutting remains at the forefront of modern manufacturing processes, enabling industries to produce higher quality products more efficiently and sustainably.