Introduction

In the agricultural industry, a tube laser cutting machine is a specialized tool used to cut and shape tubes and pipes for use in agricultural machinery and equipment. These machines utilize a high-powered laser beam to make precise cuts with a high level of accuracy and speed. The agricultural industry relies on these machines to create the structural elements that make up a wide range of machinery and equipment, including tractors, combines, and other farming equipment.

In this outline, we will explore the role of a tube laser cutting machine in the agricultural industry, including how it is used, the advantages it offers, and any challenges or limitations. By understanding the capabilities and limitations of a tube laser cutting machine, farmers and other professionals in the agricultural industry can make informed decisions about how to best utilize this technology in their projects.

What is a Tube Laser Cutting Machine?

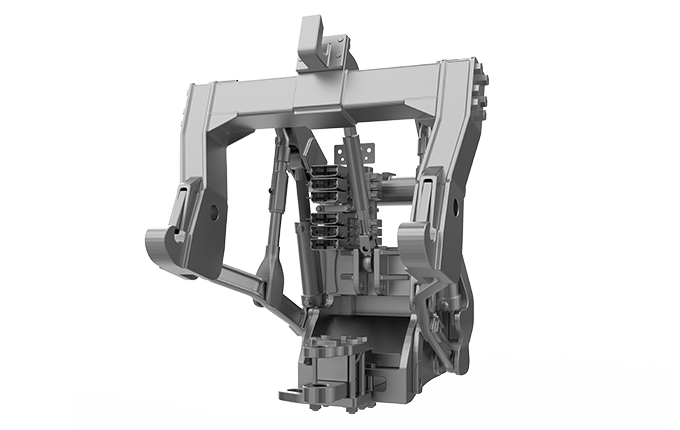

A tube laser cutting machine is an advanced piece of equipment used to cut various types of metal tubes and pipes with high precision and accuracy. It employs a laser beam to create intricate cuts and designs on the surface of the tube. The machine is capable of handling different tube profiles, such as round, square, rectangular, and oval, making it versatile for a wide range of agricultural applications.

Advantages of Tube Laser Cutting Machines

Tube laser cutting machines offer several advantages over traditional cutting methods. Some of the key advantages include:

- Precision: The laser technology used in these machines ensures precise cutting, allowing for intricate designs and complex shapes.

- Speed: Tube laser cutting machines can cut through tubes at a significantly faster rate compared to manual or other mechanical cutting methods.

- Versatility: These machines can handle a variety of tube profiles, enabling flexibility in design and customization.

- Reduced Material Waste: Laser cutting minimizes material waste as it allows for precise cuts, optimizing the usage of the metal tubes.

- Automation: Tube laser cutting machines can be automated, reducing the need for manual labor and increasing productivity.

How a tube laser cutting machine is used in the agricultural industry

In the agricultural industry, a tube laser cutting machine is primarily used for cutting and shaping tubes and pipes for use in agricultural machinery and equipment. These machines are able to make precise cuts with a high level of accuracy, which is crucial for ensuring that the structural elements of farming equipment fit together properly and are able to function as intended.

In addition to cutting tubes and pipes, a tube laser cutting machine can also be used to create precise cuts for welding and assembly. These machines are able to make cuts with a high level of precision, which can improve the overall quality and accuracy of the welded joint. This can be especially important for critical components that must be able to withstand high loads or forces.

Another benefit of using a tube laser cutting machine in the agricultural industry is the ability to significantly reduce the time and labor needed for cutting tasks. These machines are able to make cuts quickly and accurately, which can save time and labor compared to traditional cutting methods. This can help to reduce the overall cost and duration of production, and can also improve safety by reducing the amount of time that workers need to spend performing manual cutting tasks.

Advantages of using a tube laser cutting machine in the agricultural industry

There are several advantages to using a tube laser cutting machine in the agricultural industry: Increased accuracy and precision in cuts: One of the main advantages of using a tube laser cutting machine is the ability to make precise cuts with a high level of accuracy. This is especially important for farming equipment that must fit together properly and be able to function as intended. Increased efficiency and speed of production: These machines are able to make cuts quickly and accurately, which can save time and labor compared to traditional cutting methods. This can help to reduce the overall cost and duration of production. Ability to cut a variety of materials: Tube laser cutting machines are able to cut a wide range of materials, including metals and alloys. This versatility makes them useful for a variety of agricultural projects, as they can be used to cut the materials needed for a particular piece of machinery or equipment. Reduced material waste and cost savings: These machines are able to make precise cuts with minimal waste, which can help to reduce the overall cost of production. In addition, the ability to make precise cuts can help to reduce the amount of material needed for a project, further lowering costs. Overall, the use of a tube laser cutting machine in the agricultural industry can help to improve the accuracy, efficiency, and cost-effectiveness of production.

Overall, the use of a tube laser cutting machine in the agricultural industry can help to improve the accuracy, efficiency, and cost-effectiveness of production.

Challenges and limitations of using a tube laser cutting machine in the agricultural industry

There are also some challenges and limitations to using a tube laser cutting machine in the agricultural industry: Initial cost of purchasing and maintaining the machine: These machines can be expensive to purchase and maintain, which may be a challenge for some farmers or agricultural businesses. Need for skilled operators: These machines require trained operators to operate them safely and effectively. This can be a challenge for agricultural businesses that do not have trained staff or that need to train new employees on the use of the machine. Limited ability to cut thick or highly reflective materials: Tube laser cutting machines may have limitations when it comes to cutting thick or highly reflective materials. This can be a challenge for agricultural projects that require the use of these materials. Overall, while a tube laser cutting machine can offer many advantages in the agricultural industry, it is important for agricultural professionals to consider the challenges and limitations of this technology when deciding whether it is the right tool for their project.

Future Potential

The future potential of tube laser cutting machines in the agricultural industry is vast. Advancements in laser technology and machine automation will further enhance precision, speed, and versatility. As agriculture continues to evolve, these machines will play an increasingly vital role in streamlining manufacturing processes and meeting the industry’s demands for efficiency and sustainability.

Conclusion

In conclusion, the role of a tube laser cutting machine in the agricultural industry is crucial for increasing accuracy, efficiency, and cost-effectiveness in the production of agricultural machinery and equipment. These machines are able to make precise cuts with a high level of accuracy, which is essential for ensuring that farming equipment fits together properly and is able to function as intended. In addition, the ability to make cuts quickly and accurately can help to reduce the time and labor needed for cutting tasks, saving time and money on production.

However, it is important to consider the challenges and limitations of using a tube laser cutting machine, including the initial cost of purchasing and maintaining the machine, the need for skilled operators, and the limited ability to cut thick or highly reflective materials. By understanding the capabilities and limitations of this technology, agricultural professionals can make informed decisions about how to best utilize it in their projects.