Introduction: Basics of laser cutting

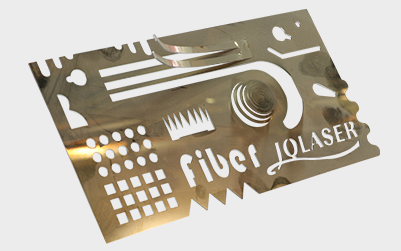

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The material to be cut is placed on a bed, and the laser beam is fired through a nozzle at the material.

What is a laser cutting machine?

Laser cutting machines are mainly used for cutting and engraving. But what are they, and how do they work?

A laser cutting machine uses a high-powered laser to cut and engrave materials. The laser is focused into a beam that is then directed at the material to be cut or engraved. The material is heated up by the laser beam and vaporized, leaving a clean, precise cut or engraving.

Applicable industries of Laser cutting machine

Laser cutting machines are used in a variety of industries, including aerospace, automotive, electrical, and manufacturing. They are also used in the printing, packaging, and textile industries. Laser cutting machines can cut a variety of materials, including metals, plastics, and composites. For example, One of the most common industries that use laser cutting machines is the automotive industry. Laser cutters are used to create a variety of parts and components for cars and trucks. They can be used to cut metal, plastic, and glass, making them perfect for creating car windows, headlights, and taillights. Meanwhile, the aerospace industry is another major user of laser cutting machines. These machines are often used to create aircraft parts and components. They can be used to cut aluminum, stainless steel, titanium, and other metals. The medical industry is also a major user of laser cutting machines.

Type of use of Laser cutter

Soudage au laser

Laser welding is a type of laser cutting that uses a high-powered laser to fuse two pieces of metal together. Laser welding is often used in the automotive industry to weld together car parts. It is also used in the aerospace industry to weld together airplane parts.

Laser cutting

Laser cutting is a type of technology that uses a laser to cut materials. It is commonly used in industrial manufacturing but is also starting to be used by hobbyists and artists.

Laser cutting can be used to cut through thick materials, or to make very intricate cuts. It can also be used to engrave images or text onto surfaces.

Laser engraving

Laser engraving is a type of laser cutting that uses a focused beam of light to create precise designs, patterns, and images on a variety of materials.

Laser engraving is an incredibly versatile technology that can be used for a wide range of applications, from creating personalized gifts to signage and industrial markings.

What can laser cutting machines be used for?

Laser cutting machines are used in a wide variety of industries for cutting materials of all shapes and sizes. Some of the most common materials that are cut with lasers include: paper, cardstock, plastics, metal, and glass. There are many different types of laser cutting machines, each designed for a specific type of material or application. For example, some laser cutting machines are designed for cutting intricate designs in paper, while others are designed for cutting metal parts to extremely precise dimensions.

-Cutting paper for scrapbooking, card making, and other paper crafts

Paper is a delicate material, and it can be difficult to cut it with traditional methods such as scissors or knives. Laser cutting machines make it possible to achieve clean, precise cuts on paper without damaging it. This makes them ideal for scrapbooking, card making, and other paper crafts.

-Cutting plastics for model making, prototypes, and product design

In the woodworking industry, laser cutting machines are commonly used to create precise cuts and patterns in the wood. In the plastics industry, laser cutting machines are used to cut plastics into a variety of shapes and sizes. In the metalworking industry, laser cutting machines are used to cut metals into thin sheets or strips. Laser cutting machines are also commonly used in the glass industry to cut glass into a variety of shapes and sizes.

-Cutting metal for sheet metal fabrication, machining, and other industrial applications

They can be used for cutting metal, plastics, wood, and other materials with high accuracy and little to no heat affected zone. Laser cutters are commonly used in sheet metal fabrication, machining, and other industrial applications where precise cuts are required.

-Cutting glass for stained glass, mosaics, and other glass crafts

Laser cutting machines can be used for cutting glass for stained glass, mosaics, and other glass crafts. Laser cutting machines are precise tools that can cut through a variety of materials with ease. This makes them ideal for cutting glass, which requires a high level of precision. Laser cutting machines can also be used to engrave designs into glass. This is often done for decorative purposes, but can also be used to create functional items such as engraved drinking glasses.

Basic advantages of laser cutting

Laser cutting machines offer many advantages over other methods of cutting materials. Some of the most significant advantages include:

-Precision: Laser cutting machines can cut material with a very high level of precision, making them ideal for cutting complex designs or for cutting parts to extremely precise dimensions.

-Speed: Laser cutting machines can cut material very quickly, making them ideal for high-volume production.

-Versatility: Laser cutting machines can be used to cut a variety of different materials, including paper, plastic, metal, and glass.

Factors to Consider When Choosing a Laser Cutting Machine

When selecting a laser cutting machine, several factors should be taken into consideration to ensure the machine meets specific requirements. These factors include:

Puissance et Wattage

The power and wattage of a laser cutting machine determine its cutting capabilities. Higher wattage machines can cut through thicker materials and offer increased cutting speeds. Understanding the desired cutting requirements is essential in choosing the appropriate power level.

Cutting Bed Size

The cutting bed size of a laser cutting machine determines the maximum dimensions of the material it can accommodate. It is important to choose a machine with a cutting bed size that matches the intended application to avoid limitations.

Material Compatibility

Different laser cutting machines are optimized for specific materials. Considering the types of materials that will be frequently cut is crucial in selecting a machine with suitable power and wavelength specifications.

Budget and Cost

Budgetary constraints play a significant role in the selection process. Evaluating the initial investment, maintenance costs, and operational expenses will help identify a machine that meets both requirements and financial considerations.

Safety Precautions for Using Laser Cutting Machines

While laser cutting machines offer numerous benefits, it is important to prioritize safety when operating these powerful tools. Some essential safety precautions include:

- Wearing appropriate protective gear, such as safety glasses and gloves, to prevent exposure to the laser beam and debris.

- Ensuring proper ventilation and extraction systems are in place to remove any fumes or hazardous byproducts generated during the cutting process.

- Following manufacturer guidelines and regular machine maintenance to keep the equipment in optimal working condition.

- Providing proper training to operators to ensure they understand the potential risks and safe operating procedures.

Conclusion

In conclusion,a laser cutting machine is used for a variety of purposes such as cutting and engraving. It is a versatile tool that can be used for both personal and commercial projects. If you are looking for a way to add a personal touch to your products or gifts, consider investing in a laser cutting machine.