M2

Start off on the right foot

Round, square,

rectangular tubes

120 kg

(15 to 230 mm)

The best of technology in the smallest member of the family

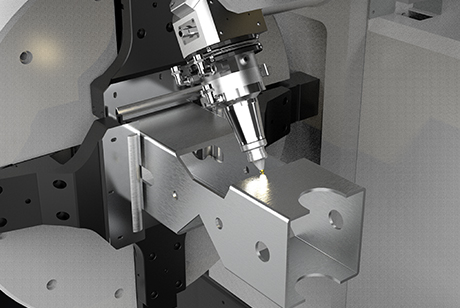

With the installation of the latest TubeCutter cutting head on the M series, you can manufacture superior quality components. The automatic focus and integrated laser parameter management eliminate the need for any manual adjustments.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

Adopt the overall heavy-duty high-strength cold-rolled pipe plate welded bed, insert structure, equal strength welding; high precision automatic pneumatic chuck, precision gear drive, powerful automatic centering function, convenient and efficient, pneumatic chuck one key to open the clamp, super strong pneumatic clamping force, heavy pipe clamping more firmly; follow the design of support, independent servo motor real-time control to adjust the pipe lifting height, to prevent pipe sagging

Form and content in a single solution

The best choices show their value over time

The fully automatic loading mechanism can be tailored to meet specific customer needs, enabling pipes to be loaded automatically without any manual intervention. This streamlined process enhances production efficiency, making it both convenient and efficient.

The semi-automatic feeding mechanism can be customized to accelerate pipe feeding and effectively reduce manual labor time, ensuring a smoother cutting process.

Machine performance will remain robust, reliable and productive year after year.

The software suite that creates value

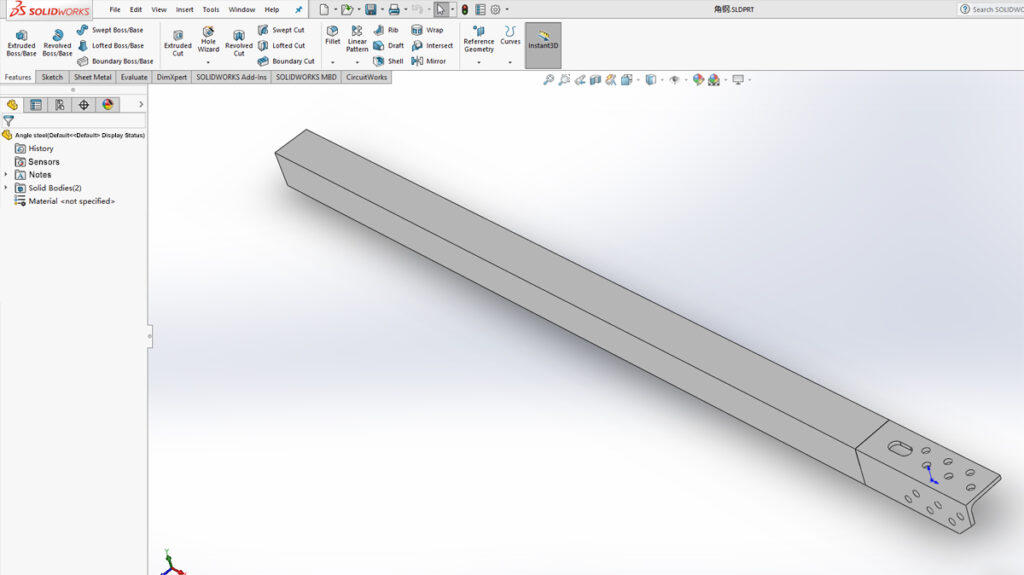

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.