Introduction

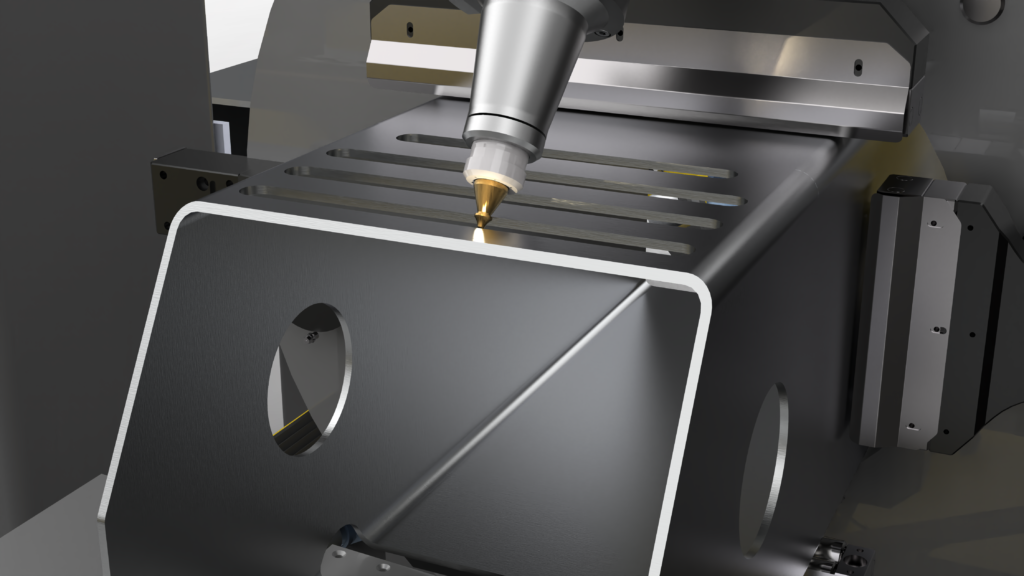

laser tube cutting machines combine technology and precision for efficient, accurate cutting of materials for manufacturing purposes and other related applications. Laser tube cutting machines are a great way to save time and resources while maximizing productivity. By providing fast and accurate cuts, laser tube cutting machines are a great ally for companies operating in a wide variety of industries. In this article, you will learn the benefits of using laser tube cutting machines, how to streamline tube cutting with them, what to look for in a tube cutting laser, and more.

Benefits of Laser Tube Cutting Machines

There are many advantages to using a laser tube cutting machine, including:

- Speed. Laser cutting machines are faster and more accurate than manual cutting.

- Precision. Laser cutting machines can cut with extreme precision, and the accuracy is not affected by the operator.

- Versatility. Laser tube cutting machines can be used to cut a variety of materials and thicknesses.

In addition, laser tube cutting machines are extremely energy efficient, enabling you to save money on energy costs while still getting quick and accurate cuts.

Streamline Tube Cutting with Lasers

Streamlining the tube cutting process is essential for optimizing productivity when using laser tube cutting machines. By implementing efficient techniques and tools, you can enhance the efficiency and effectiveness of your tube cutting operations. Here are some strategies to consider.

One approach to streamline tube cutting is to utilize cylinders for automatic loading and unloading of long pipes and tubes. This automated process eliminates the need for manual handling, saving time and reducing the risk of errors. Especially when dealing with a large volume of identical pieces, the use of cylinders can significantly increase efficiency and throughput. With the ability to load and unload tubes automatically, the machine can operate continuously without interruptions, resulting in improved productivity and reduced downtime.

Another valuable tool for streamlining tube cutting is nesting software. This software optimizes material usage by arranging the shapes to be cut in the most efficient way, reducing waste and maximizing the utilization of the available material. By minimizing the number of repositioning steps required, nesting software helps streamline the cutting process, further enhancing productivity. It eliminates the need for manual adjustments and reduces setup time, allowing for smoother and more efficient operations.

When it comes to laser tube cutting, utilizing the right equipment is crucial. TRUMPF, for example, offers laser tube cutting machines designed for maximum productivity and versatility. These machines can eliminate entire process steps while expanding the range of parts that can be produced. With their robust construction, they can handle even XXL tubes, making them suitable for a wide range of applications[3].

By incorporating these strategies and leveraging the capabilities of laser tube cutting machines, manufacturers can achieve significant improvements in productivity, efficiency, and accuracy. Streamlining the tube cutting process not only saves time but also reduces material waste and enhances overall operational effectiveness. It allows for the precise and rapid production of complex tube shapes, meeting the demands of various industries such as automotive, aerospace, and construction.

What to Look for in a Tube Cutting Laser

When looking for a laser tube cutting machine, it’s important to take into account the size of the pipe and the size of the cuts you need to make. For smaller pipes, consider a fiber laser tube cutting machine, which is more efficient and can deliver higher accuracy than other types of lasers. You should also consider the features and options available, such as the ability to manually adjust the laser beam parameters, the number of axes that the machine has and the power of the laser. Finally, look at the amount of maintenance the machine needs and if it is user-friendly.

Adopting Laser Tube Cutting into Your Manufacturing Process

To fully optimize your tube cutting productivity, it’s important to make sure that the laser machine is properly integrated into your existing manufacturing process. This means taking into account the set-up and preparation time, the loading and unloading time for both pipes and material, as well as the post cutting operations. In addition, it’s also important to ensure that the cutting parameters (i.e. laser power, cuts/minute, etc.) are properly set up, that the machine is using the appropriate materials, and that the machine is properly maintained in order to minimize downtime.

Automating Tube Cutting with Lasers

Automation can also be a great way to maximize the efficiency of laser tube cutting machines. Automation can be achieved by integrating the laser into your existing material handling equipment, such as automated storage and retrieval systems, and by adding software that controls the cutting process, such as CAD/CAM software. Moreover, automation can make the tube cutting process easier and more efficient, as it eliminates manual intervention and freeing up workers to focus on other tasks.

Options for Increasing Tube Cutting Laser Efficiency

There are several ways to increase the efficiency of your tube cutting laser. The most common way is to reduce the number of passes for each cut. This can be done by increasing the power of the laser or by reducing the cutting speed. Additionally, you can use a thinner cutting kerf to reduce material wastage. Replacing worn out optical parts, such as lenses and mirrors, can also improve the efficiency of the laser tube cutting process, as they can degrade over time and cause the laser to become less efficient.

Operating a Laser Tube Cutting Machine Safely and Efficiently

Safety is paramount when operating laser tube cutting machines. Understanding the potential hazards associated with laser technology and implementing strict safety protocols are essential to prevent accidents and ensure a secure working environment. Operators should be well-versed in safety procedures and equipped with the necessary protective gear to minimize any risks. Additionally, adhering to maintenance schedules and conducting regular inspections is crucial for the machine’s longevity and optimal performance.

Maintenance Tips to Prolong the Lifespan of Your Laser Tube Cutting Machine

To maximize the lifespan and efficiency of your laser tube cutting machine, regular maintenance is imperative. This includes routine checks of the machine’s components, such as the lenses, nozzles, and mirrors, to ensure they remain clean and undamaged. Regular cleaning and lubrication of the machine’s mechanical parts also prevent wear and tear, reducing the likelihood of unexpected breakdowns and costly repairs. Creating a maintenance schedule and adhering to it diligently is key to avoiding downtime and preserving the machine’s productivity.

Integrating Laser Tube Cutting Machines into Manufacturing Processes

Integrating laser tube cutting machines seamlessly into existing manufacturing processes requires careful planning and coordination. Identifying the stages of production where the machine can significantly enhance efficiency and output is crucial. Incorporating the machine into a well-structured workflow ensures a smooth transition and optimized utilization, ultimately contributing to an increase in overall productivity and improved product quality.

Advanced Techniques and Features for Maximizing Productivity

Beyond the basic functionalities, exploring the advanced features and techniques of laser tube cutting machines can unlock new levels of productivity and innovation. This includes utilizing 3D cutting capabilities, implementing automated material handling systems, and integrating intelligent software for precise material optimization and efficient production scheduling. Leveraging these advanced techniques empowers manufacturers to undertake complex projects with enhanced speed, accuracy, and cost-effectiveness.

Exploring the Future of Laser Tube Cutting Machines in Various Industries

The future of laser tube cutting machines is promising, with continuous advancements driving their integration into an expanding array of industries. From automotive and aerospace to construction and electronics, these machines are revolutionizing the production processes, allowing for the creation of intricate components and structures with unprecedented precision. As technology evolves, laser tube cutting machines will continue to play a pivotal role in shaping the future of manufacturing and fabrication.

Real-Life Success Stories and Case Studies of Businesses Using These Machines

Examining real-life success stories and case studies of businesses that have successfully integrated laser tube cutting machines into their operations provides valuable insights and inspiration. These stories highlight the transformative impact of these machines on production efficiency, product quality, and overall business growth. Learning from the experiences of others can offer valuable lessons and best practices that can be applied to optimize one’s own manufacturing processes and achieve similar success.

Tips for Overcoming Common Challenges While Using Laser Tube Cutting Machines

Despite their numerous advantages, using laser tube cutting machines may present certain challenges. These could include issues such as material warping, excessive heat-affected zones, or difficulties with specific materials. Implementing appropriate strategies such as adjusting cutting parameters, utilizing specialized nozzles, or employing cooling techniques can help overcome these challenges effectively, ensuring consistent high-quality output and minimizing production setbacks.

Comparing Laser Tube Cutting Machines with Other Cutting Methods

While laser tube cutting machines offer unparalleled precision and speed, it is essential to compare them with other cutting methods to determine their comparative advantages and limitations. Analyzing factors such as cost-effectiveness, speed, versatility, and material compatibility enables businesses to make informed decisions regarding the most suitable cutting approach for their specific manufacturing needs. Understanding the strengths and weaknesses of each method is crucial in selecting the most efficient and cost-effective solution.

Addressing Environmental Concerns and Sustainability Aspects

As sustainability continues to be a key focus in modern manufacturing, addressing the environmental impact of laser tube cutting machines is crucial. Implementing energy-efficient practices, minimizing material waste, and utilizing eco-friendly technologies can significantly reduce the carbon footprint associated with these machines. Additionally, recycling and repurposing materials play a vital role in promoting a circular economy and reducing the overall environmental impact of manufacturing operations.

Conclusion

Laser tube cutting machines offer an efficient and accurate way to cut tubes and pipes and maximize productivity. This includes taking into account the benefits of using a laser tube cutting machine, streamlining tube cutting, looking into specific features of tube cutting lasers, integrating the laser into your manufacturing process, automating the process, and maintaining and caring for the machine. When properly used and maintained, laser tube cutting machines can be a great asset for any business.