If you’re in the iron tower industry, then you know that a tube laser cutting machine can be a valuable asset. But how do you use one effectively? In this blog post, we’ll give you some tips on how to get the most out of your tube laser cutting machine.

What is a tube laser cutting machine?

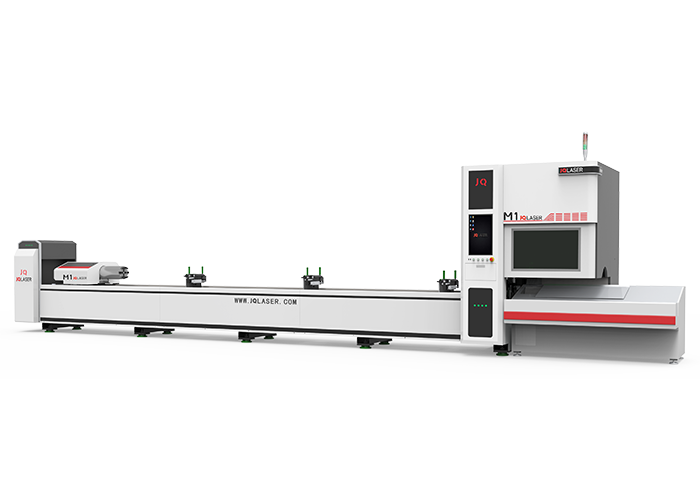

A tube laser cutting machine is a specialized piece of equipment that is used to cut tubes and pipes of various sizes. The machine uses a laser to cut through the material, which can be made from a variety of materials including metal, plastic, and glass. Tube laser cutting machines can be used for a variety of applications, including cutting pipes for the construction industry, cutting tubing for the medical industry, and cutting pipes for the automotive industry.

How does a tube laser cutting machine work?

In order to understand how a tube laser cutting machine works, it is necessary to first understand what a laser is and how it works. A laser is a beam of intensely concentrated light. Thislight is so concentrated that it can cut through metal.

When the light from a laser hits the metal, it heats up the metal until it melts. The tube laser cutting machine uses a computer to direct the laser beam as it cuts through the metal. The computer tells the laser beam where to start cutting, how deep to cut, and how to make the cuts.

What are the benefits of using a tube laser cutting machine in the iron tower industry?

When it comes to steel cutting, laser technology has many advantages over traditional methods. Laser cutting is faster, more precise, and creates less waste than other methods like plasma or waterjet cutting.

In the past, iron towers were cut using large oxy-acetylene torches. This was a very slow and inaccurate process that created a lot of waste material. Today, most iron towers are cut using laser cutting machines.

Laser cutting machines can cut very large pieces of steel quickly and accurately. They can also cut small, intricate shapes that would be impossible to cut with a torch. And because laser cutting produces very little heat, there is no risk of warping or distorting the metal.

Laser cutter machines also use less energy than oxy-acetylene torches, making them more environmentally friendly.

How to choose the right tube laser cutting machine for your business?

In order to make the best decision for your business, you need to understand what a tube laser cutting machine can do for you. These machines are designed for specific industry applications and can be used in a variety of ways. Here are some things to keep in mind when choosing the right machine for your business.

-The first thing you need to consider is the material you will be cutting. There are different machines designed for different materials, so it is important to choose one that is specifically designed for the material you will be using.

-The second thing to consider is the thickness of the material you will be cutting. This will determine the size of machine you need and also the type of power supply you will need.

-The third thing to consider is the accuracy of the cuts you need to make. There are different machines that offer different levels of accuracy, so it is important to choose one that meets your specific requirements.

Now that you know what to look for in a machine, it is time to start shopping around. Talk to different manufacturers and dealers and get quotes on different models. This will allow you to compare prices and features and find the perfect machine for your business needs.

How to set up a tube laser cutting machine?

Sample video:

There are a few key considerations when setting up a tube laser cutting machine to process ferrous materials. Here are four tips to help ensure successful tube laser cutting of iron and steel:

Clamp diameters should be sized according to the wall thickness of the tube being processed. For example, when processing 3mm thick tubing, clamp diameters should be around 50mm. This will help prevent deformation of the tube during processing.

The lens focal length should be set according to the material being processed. For example, when processing stainless steel, a focal length of 1.1mm is typically used. By contrast, when processing carbon steel, a focal length of 1.6mm is usually used.

The power output should be set according to the thickness of the material being processed. When cutting carbon steel, for example, a power output of 1000W is typically used. When cutting stainless steel, a power output of 1500W is typically used.

The feed rate should be set according to the thickness of the material being processed. When cutting carbon steel, for example, a feed rate of 12m/min is typically used. When cutting stainless steel, a feed rate of 8m/min is typically used.

How to operate a tube laser cutting machine?

The first thing you need to do when operating a tube laser cutting machine is to read the operators manual that came with the machine. This will give you a good understanding of how the machine works and what its capabilities are. Once you have read the manual, it is time to become familiar with the control panel. The control panel is where you will input all of your settings and information.

Be sure to set up your work area in a well-lit and well-ventilated space. You will also want to make sure that there is enough room for you to move around the work area without bumping into anything. It is also important to wear proper safety gear when operating a tube laser cutting machine. This includes safety glasses, gloves, and ear protection.

Once you have your work area set up and you are wearing the proper safety gear, it is time to turn on the machine. Start by selecting the cutting mode on the control panel. Then, select the tube diameter that you will be using for your project. Next, select the material thickness that you will be working with. Finally, select the speed at which you would like the laser to cut through the material.

After all of your settings have been inputted on the control panel, it is time to load your material into the loading tray of the machine. Make sure that your material is placed in the tray in such a way that it will not get tangled up in the laser beam or cause any other problems during operation. Once your material is loaded into the tray, close the loading door and press start on the control panel.

How to troubleshoot a tube laser cutting machine?

If your tube laser cutting machine is not functioning properly, there are a few steps you can take to troubleshoot the issue.

First, check that all of the machine’s power sources are turned on and that the fuse has not blown.

Next, check that the control panel is set to the correct settings for the material you are trying to cut.

If the machine is still not functioning properly, contact the manufacturer or a qualified technician for assistance.

How to maintain a tube laser cutting machine?

Laser cutting machines are an important part of the iron tower industry. They are used to cut and shape metal tubes into the desired shapes and sizes. In order to keep these machines running properly, it is important to perform regular maintenance on them.

Some of the things that should be done on a regular basis include:

- Cleaning the machine regularly. This will help to prevent build-up of debris and dust, which can cause the machine to malfunction.

- Lubricating the moving parts. This will help to keep them moving smoothly and prevent wear and tear.

- Checking the alignment of the laser beam. This should be done periodically to ensure that the beam is correctly aligned with the cutting area.

- Adjusting the gas pressure. This should be done according to the manufacturer’s instructions in order to ensure that the correct amount of gas is being used for cutting.

It is also important to have a qualified technician perform any necessary repairs or replacements on the machine. This will help to keep it running properly for a longer period of time.