Laser cutting mechanism and evaluation index

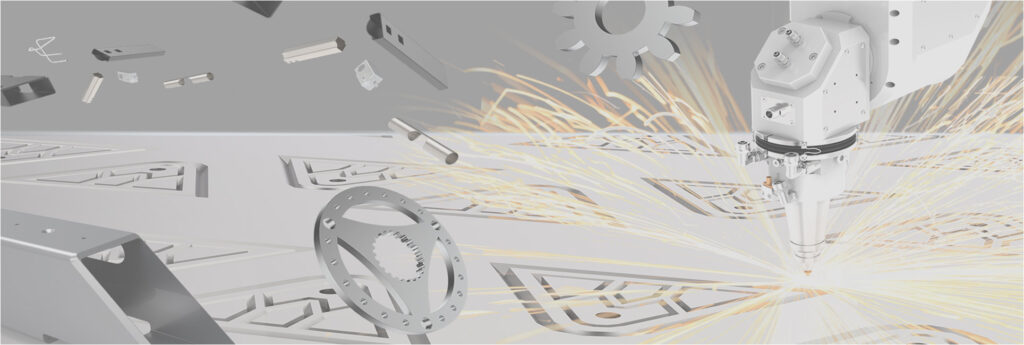

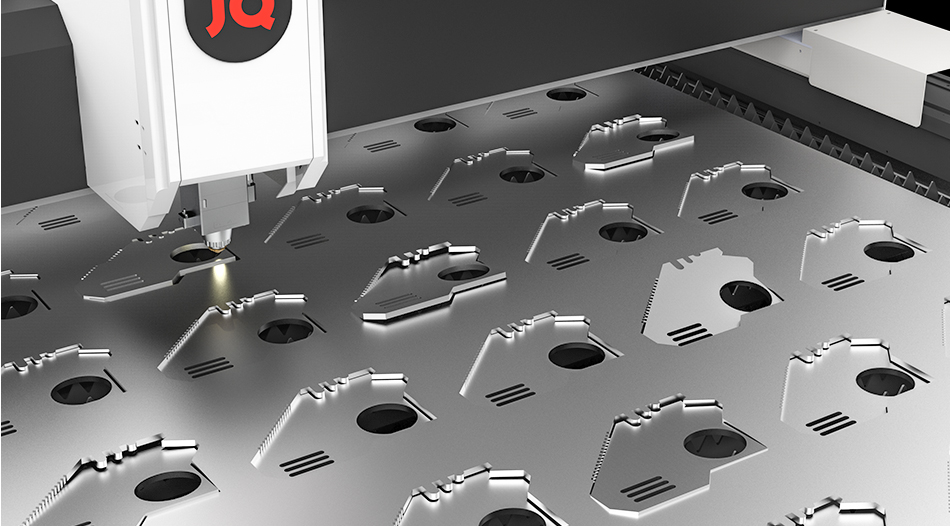

Principle of laser cutting Laser cutting is to focus the laser beam into a small spot, causing it to act on the material. The laser power density can reach more than 106 W/cm2. Under such high power density laser irradiation Under the action, the metal material quickly vaporizes and evaporates, forming holes. The molten metal […]

Application of high-power laser cutting technology

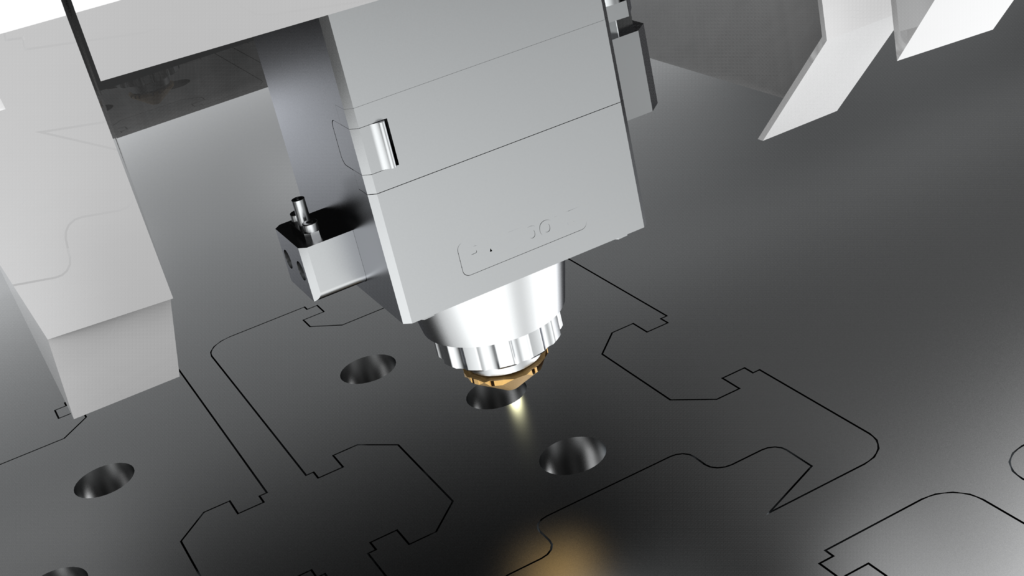

Laser cutting principle Laser cutting uses a focused high-power, high-energy-density laser beam to irradiate onto the plate to be processed, causing the irradiated material to quickly melt, vaporize, ablate or reach the ignition point. The high-speed airflow blows away the molten material and cuts the sheet. Precautions during the production process of laser cutting equipment […]

Design of a flexible production line system for plate laser cutting

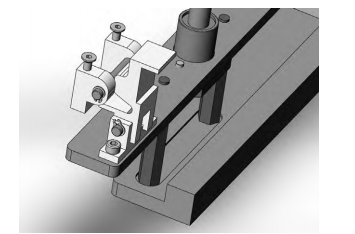

In order to improve the consistency and yield rate of products after laser cutting, it is necessary to accurately position the plates that are loaded during cutting. However, because wooden boards have a certain degree of elasticity and have large dimensional errors and are easily deformed, and the boards are stacked at random positions in […]

Common faults and solutions of CNC laser cutting machines

Overview of CNC laser cutting machine Laser cutting machine consists of CNC system, external optical path system, water cooling machine, cutting system and laser. When the laser cutting machine is working, it uses energy to cut metal materials, non-metal materials, composite materials, and organic materials. Laser cutting technology has many advantages, such as fast processing […]

Laser cutting technology application research on titanium alloy forgings

In the forging industry, laser cutting technology has been widely used in the flash and skin of structural steel and stainless steel forgings, while laser cutting technology on titanium alloy forgings is still a banned or restricted process in China. However, with the rapid development of laser cutting equipment, the improvement of laser equipment power […]

Basic principles and influencing factors of laser cutting

1 Principle of Laser Cutting Laser is the product of stimulated radiation. Its production is inseparable from three key elements: working material, pump and resonant cavity. After absorbing energy, low-energy level particles will transition to high-energy level orbits, but the state of high-energy level particles is It is unstable and will fall to a low […]

Research status of laser cutting technology

Laser cutting technology is a cutting technology that uses laser to process planes. It has attracted the attention of many scholars due to its advantages such as high processing precision and no pollution. With the continuous development and progress of science and technology, people have put forward higher requirements for the performance of parts, so […]

Process optimization of hydraulic support structural parts based on laser cutting

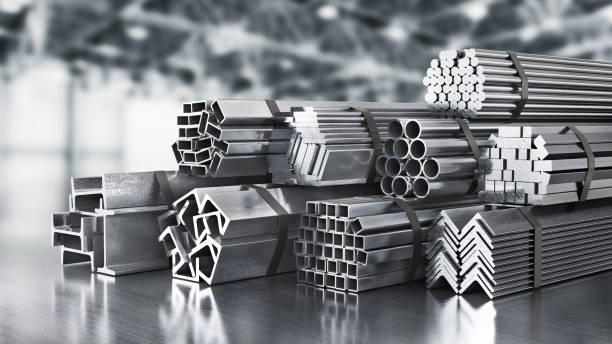

The main part of the hydraulic support is composed of structural parts of medium-thick steel plates and oil cylinders. As shown in Figure 1, the structural parts composed of medium-thick steel plates account for about 79% of the total weight of the hydraulic support. The raw materials are mainly medium-thick steel plates with a thickness […]

Laser ring cutting and hole making process for laminated aluminum alloy sheets

Among laser cutting methods, there are four main cutting methods: vaporization cutting, melting cutting, oxygen-assisted melting cutting and controlled fracture cutting. This article uses the melting cutting method to make the material at the laser spot reach the melting point, and at the same time blows or removes it with the help of auxiliary gas […]

Application of laser cutting technology in marine engineering construction

Laser technology is a remarkable achievement in the science and technology industry in the middle and late part of the last century. Its emergence has greatly promoted the progress of human civilization in various industries. In various fields, laser technology has been widely used in recent years, and its application in the offshore engineering and […]