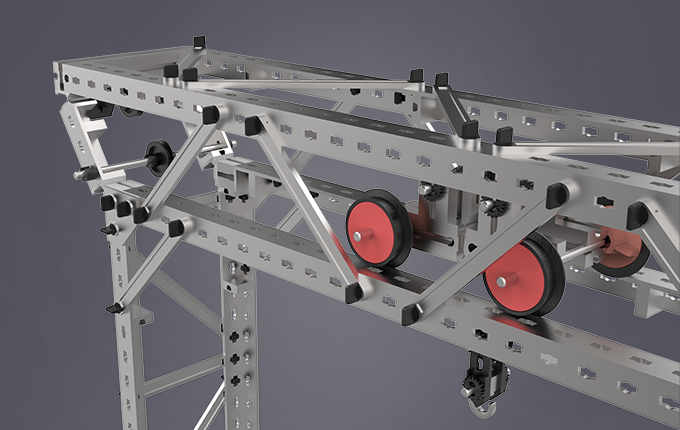

Attrezzature per gru

As the world progresses, so too does the technology that we use to make our lives easier. One such technology is laser cutting, which has a wide range of applications from manufacturing to food production. And while this technology is still relatively new, it’s already having a significant impact on the crane equipment industry.

At our company, we have a team of experts who are well-versed in laser cutting technology. We work with our clients in the crane equipment industry to help them leverage this technology to grow their businesses rapidly. By doing so, we’re able to help them stay ahead of the curve and remain competitive in an ever-changing marketplace.

So far, we’ve been extremely successful in helping our clients achieve their goals. In fact, many of them have seen their businesses grow exponentially as a result of working with us.

Faster

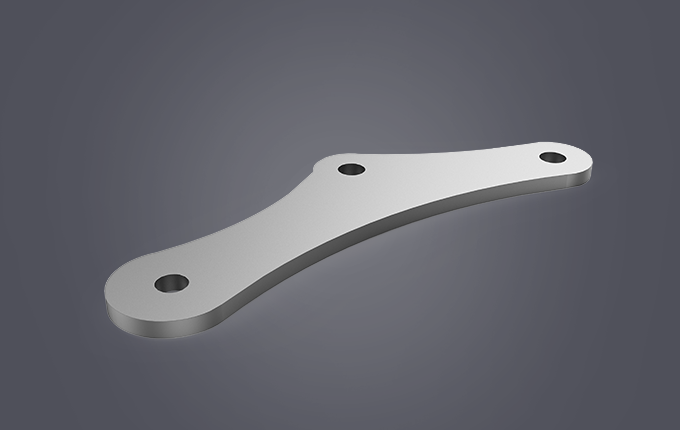

Laser cutting is a more precise method than traditional cutting methods, which can be important when fabricating parts for cranes and other equipment. In addition, taglio laser can be done much faster than traditional methods, which can help to reduce production times.

Meet various needs

Laser cutting machine can cut various shapes of holes with high precision, which can meet the requirements of different crane equipment.

Less waste

laser cutters generate less waste material than traditional methods, which helps to keep costs down. For all these reasons, taglio laser is becoming an increasingly popular choice for those in the crane and equipment industry.