Introduzione

The advent of laser cutting has revolutionized the industrial landscape, reshaping prior notions of efficiency, accuracy and productivity. As laser cutting technology continues to advance and become more accessible, innovative applications of this technology are making waves across a variety of industries. Tube laser cutting machines, in particular, have the potential to open an entirely new world of design possibilities and manufacturing potential, making them especially appealing in a market that increasingly values efficiency, transportation weight, and customized designs. In this article, we will explore the innovative applications of tube laser cutting machines in various industries.

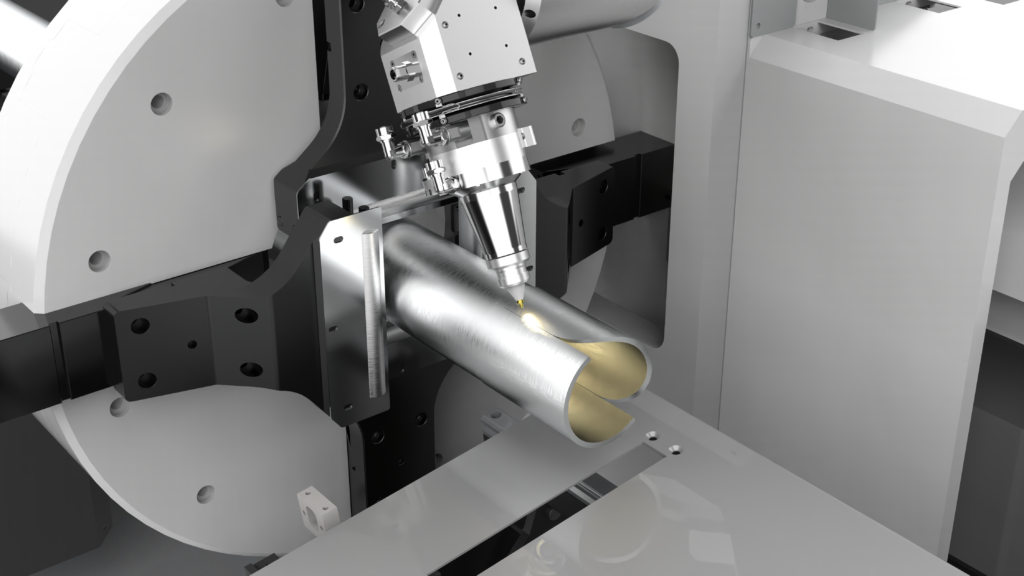

Unlocking Productivity Through Tube Laser Cutting

An integral component of the industrial revolution has been an unwavering commitment to efficiency and productivity, and tube laser cutting machines have risen to that challenge. These machines can make quick work of complex designs and intricate shapes without compromising accuracy. With customizable programs and the ability to accurately produce intricate shapes, the level of productivity that can be achieved with tube laser cutting is unparalleled. This makes tube laser cutting technology ideal for a variety of industries, from automotive to aerospace, where speed and accuracy are both essential.

Unbound Limits: Harness the Power of Imagination

The flexibility of tube laser cutting machines makes it possible to shape components with almost limitless possibilities. With these machines, the only limitation is the imagination – thanks to their unique design and advanced capabilities, virtually any shape can be produced with unparalleled speed and accuracy. This makes them especially useful for industries that require complex and customized designs, as it allows for more freedom in the production process.

Redefining Efficiency in the Automotive Sector

In the automotive industry, tube laser cutting machines have become instrumental in shaping the production process. By enabling precise and intricate cuts, these machines have facilitated the creation of complex designs and structures for automotive parts. With improved accuracy and speed, manufacturers have experienced heightened productivity while maintaining exceptional quality standards.

Transforming Architectural Possibilities

Architectural marvels owe much to the versatility of tube laser cutting machines. From intricate metal frameworks to elaborate designs, these machines have allowed architects to bring their visionary designs to life. The precision of the cuts ensures seamless integration of various components, leading to the creation of stunning and durable structures that stand the test of time.

Revolutionizing the Aerospace Industry

In the aerospace sector, the demand for precision and durability is paramount. Tube laser cutting machines have answered this call by offering an efficient method for fabricating intricate components with exacting specifications. From lightweight frames to specialized parts, these machines have facilitated the production of high-performance components that adhere to stringent safety and quality standards.

Catering to the Ever-Evolving Needs of the Medical Field

In the medical industry, the use of tube laser cutting machines has paved the way for the manufacturing of intricate medical devices and equipment. From surgical instruments to specialized components, these machines have streamlined the production of complex and delicate tools, ensuring precision and reliability in medical procedures. This technology has significantly contributed to the advancement of medical practices worldwide.

Enhancing Productivity in the Furniture Manufacturing Industry

The furniture manufacturing sector has embraced tube laser cutting machines to cater to the growing demand for customized and intricately designed furniture pieces. These machines have enabled manufacturers to create unique and elaborate designs efficiently, allowing them to meet the diverse preferences of consumers. With increased speed and accuracy, the furniture industry has witnessed a significant boost in productivity and customer satisfaction.

In addition to their precision and versatility, laser cutting machines offer numerous other advantages. They facilitate faster production cycles, enabling manufacturers to meet tight deadlines and customer demands. The non-contact cutting method minimizes material distortion, reducing waste and optimizing material usage. Furthermore, laser cutting machines are highly automated, allowing for increased productivity and efficiency. With the ability to program and automate the cutting process, manufacturers can achieve consistent and repeatable results, eliminating human error and enhancing overall quality control.

As the Industrial Revolution brought about unprecedented societal and economic changes, the Industrial Revolution of laser cutting in manufacturing is set to have a similar transformative impact. The continued development and innovation in laser cutting technology will open up new possibilities for customization, efficiency, and design freedom in the manufacturing industry. Manufacturers who embrace this revolution will gain a competitive edge by delivering high-quality products with greater speed and precision.

Revolutionary Expansion: Metals, Textiles, Plastics – and More

The range of materials that can be processed by tube laser cutting machines is vast. These machines are capable of cutting and engraving a variety of metal, plastic, and textile materials, giving them the ability to quickly and accurately produce complex components with unparalleled accuracy. This makes them especially useful for industries where a variety of raw materials are employed, in order to maximize efficiency and reduce waste.

Bending and Cutting Together: Limitless Geometric Possibilities

The combination of bending and cutting capabilities offered by tube laser cutting machines gives manufacturers the unique ability to produce intricate shapes with unparalleled speed and accuracy. By combining these capabilities, manufacturers have the ability to customize components with an impressive degree of detail, allowing for unique and complex designs that were previously unachievable.

Finer Details: Automated Precision for Impeccable Craftsmanship

Tube laser cutting machines are equipped with advanced automated technology that enables them to precisely cut intricate shapes with astounding accuracy. This automated precision ensures that every component produced is of the highest possible quality, thus enabling manufacturers to specialize in impeccable craftsmanship.

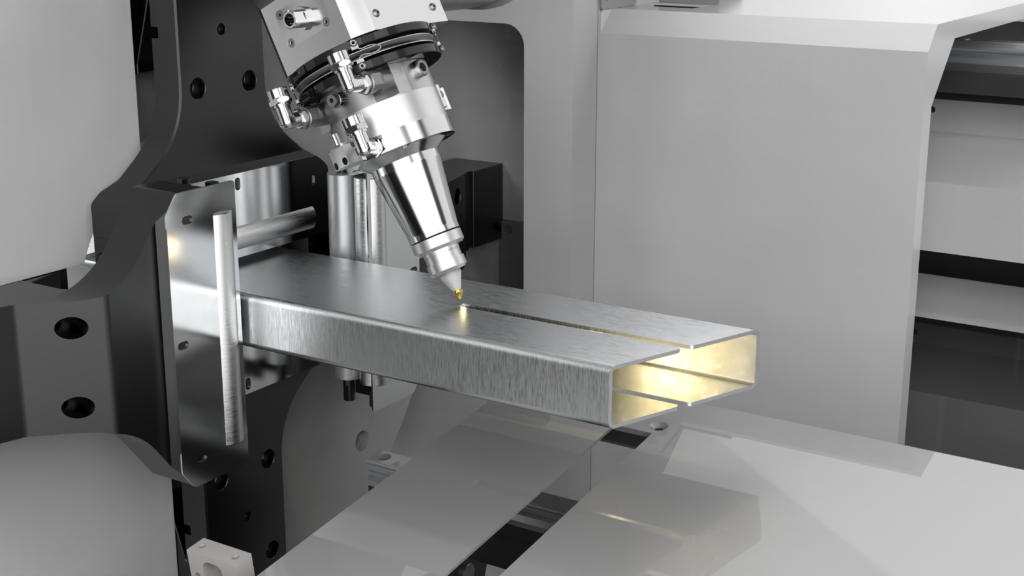

Streamlining Sheet Metal Fabrication: Laser Frequency for Fast Output

Tube laser cutting machines are capable of quickly processing sheet metal, fabricating intricate geometric shapes with unmatched speed. This makes them ideal for the fabrication of sheet metal components, as tube laser cutting machines can quickly process an entire sheet at once, dramatically increasing efficiency while conserving materials.

Stepping Beyond the Norm: Tube Laser Cutting As the Next Level

The flexibility and accuracy of tube laser cutting machines give manufacturers the ability to stay ahead of the competition. Thanks to the numerous advantages that this technology provides – from its speed and accuracy to its increased efficiency – tube laser cutting takes industrial production to the next level, allowing for the production of complex components with unprecedented levels of detail and customization.

New Possibilities, New Horizons: Modernizing Industry with Tube Laser Cutting

The application of tube laser cutting technology has the potential to reshape the contemporary industrial landscape. By allowing for the rapid production of complex components with unprecedented accuracy, this technology opens up innumerable possibilities in a variety of industries. As the future of industrial production continues to evolve, tube laser cutting machines are sure to remain a key component in the continued growth and modernization of the industrial landscape.

Conclusione

The potential of tube laser cutting machines to revolutionize the industrial landscape is undeniable. With the ability to quickly produce complex components with unparalleled accuracy, this technology is unmatched in its ability to unlock unprecedented levels of productivity. As the technology continues to advance and become more accessible, there is no doubt that tube laser cutting will remain an integral component of modern manufacturing.