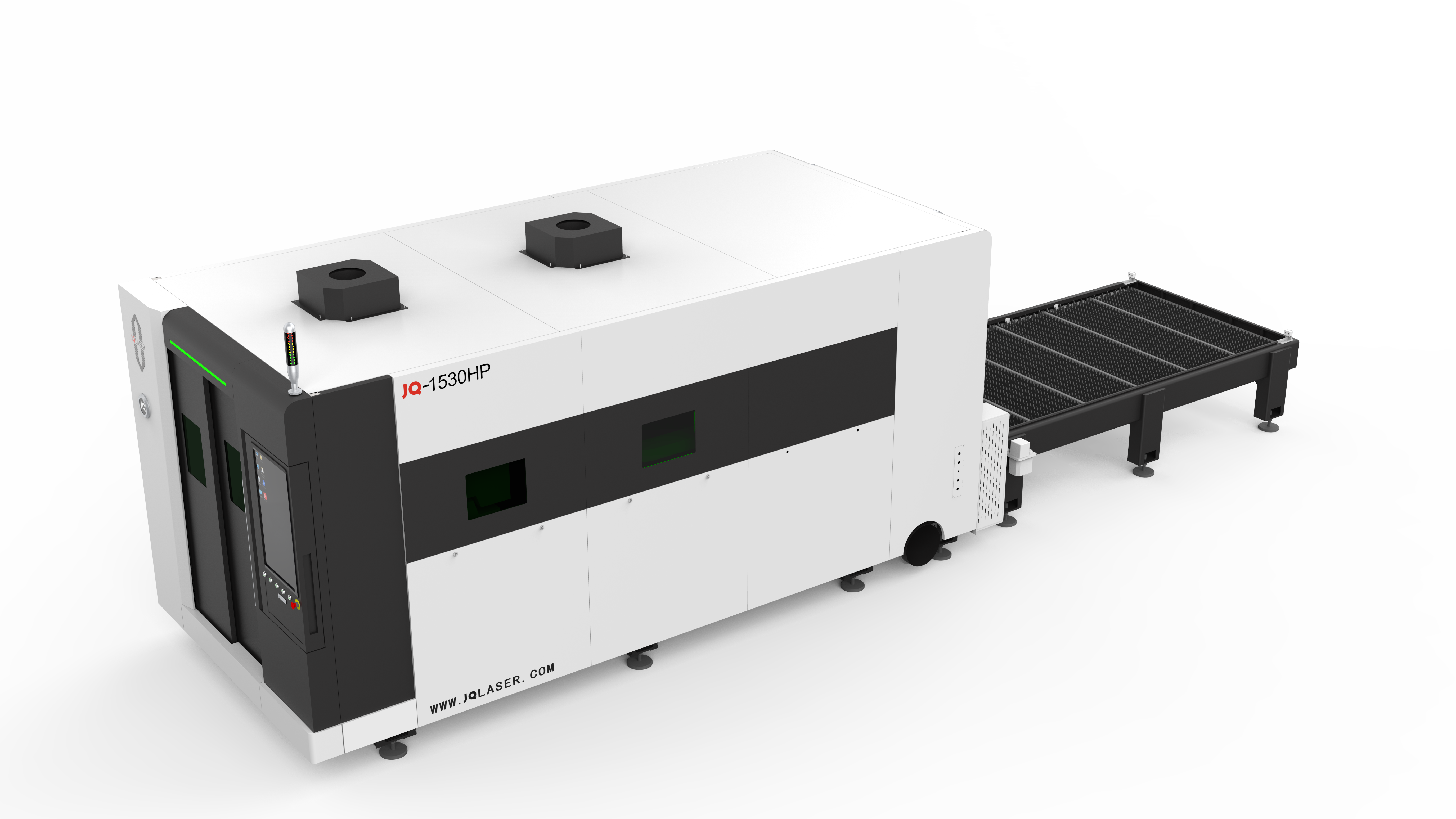

JQ-1530HP

Start off on the right foot

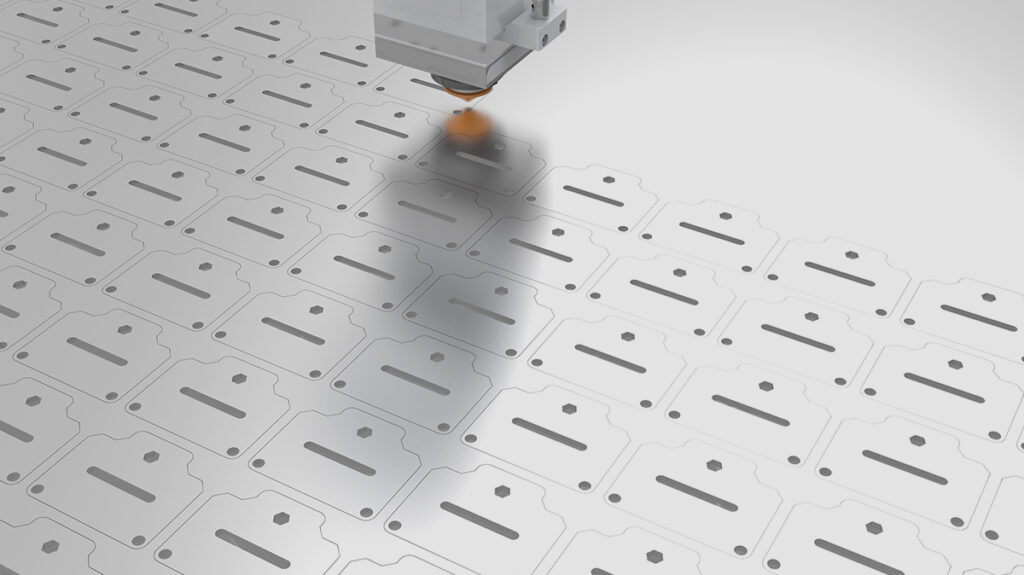

Plate cutting

Power available

6 – 12KW

Loading weight

1500KG

Working area: 3000*1500mm

X-axis travel: 1520mm

Y-axis travel: 3020mm

Z-axis travel: 1520mm

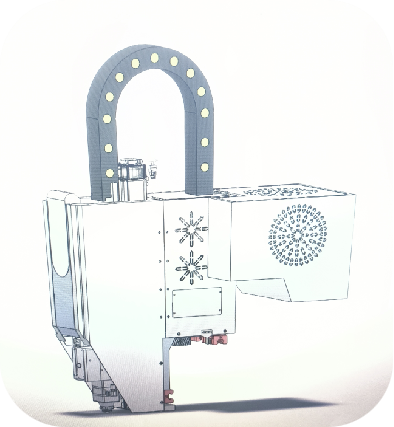

The best of technology in the smallest member of the family

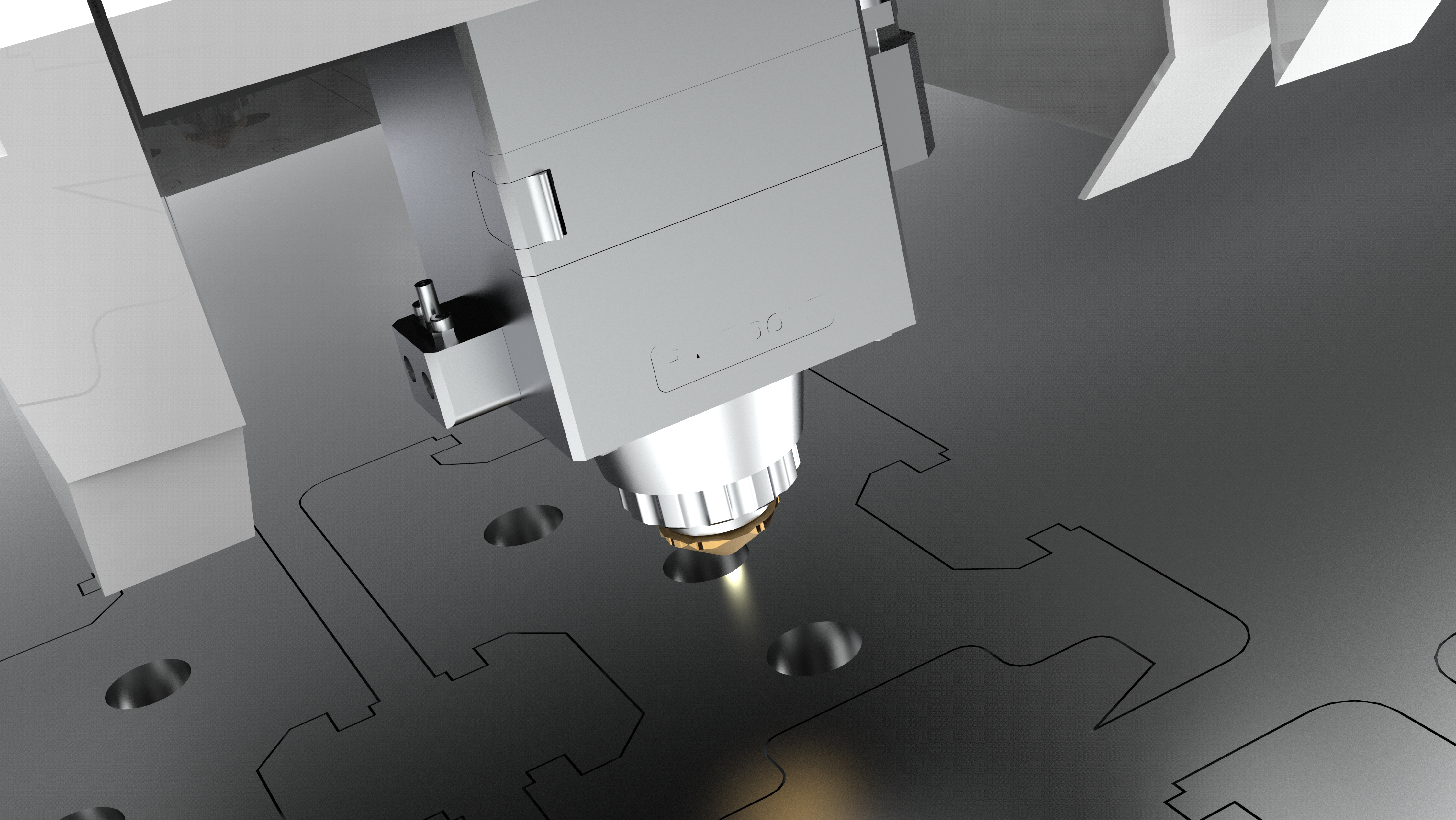

With the new Plate Cutter cutting head equipped on the JQ-1530HP, you will produce high quality parts. With automatic focus and integrated laser parameter management, there is no need for adjustments.

Performance based on robustness and, above all, reliability.

Ergonomic and accessible

Shipping solutions such as shipping in a container without removing sheet metal and beams

Improved bed anti-burning material: graphite plate changed to cast iron plate.

Cast iron plate installation is better than graphite plate. Cast iron is hung, while graphite plate needs to be installed and fixed by separate sheet metal;

The strength of cast iron is better than that of graphite plate. Cast iron is not easy to break and has a long service life, while graphite is easy to break and has a short cycle (30 yuan/KG);

Cast iron has a relatively high carbon content and is not easy to melt with ordinary slag. It is easy to clean slag and can be used repeatedly;

Cast iron has a relatively high residual value, while graphite plate can be almost ignored.

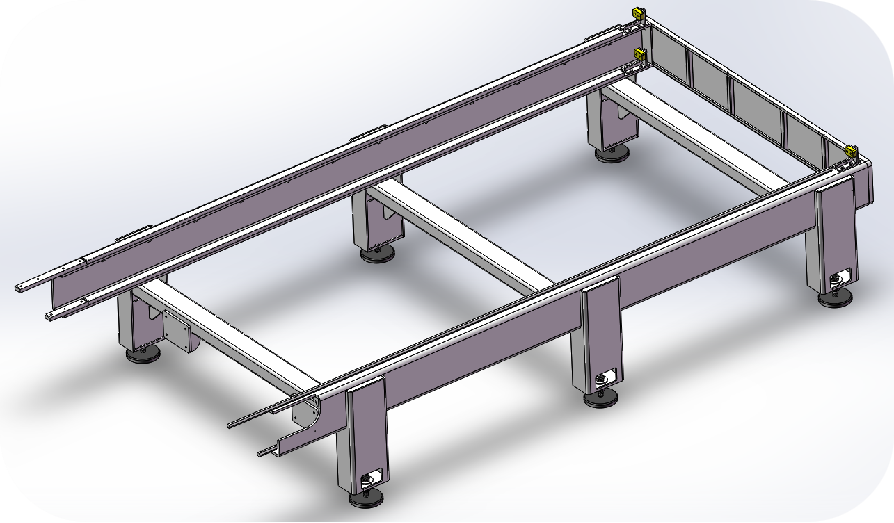

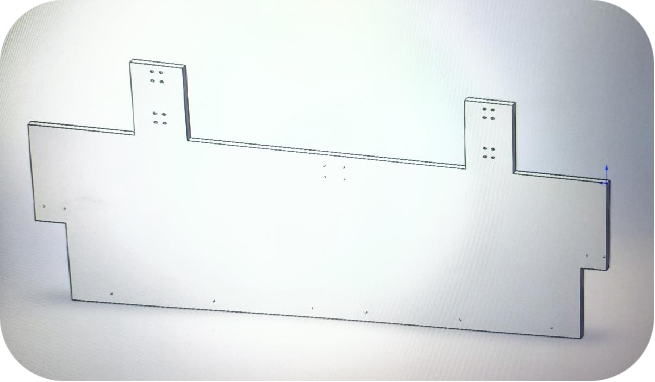

The bed structure adopts plate-welded box-type frame structure, rationally arranges rib plates, and adopts plug-in structure for key overlap. Strict welding process is formulated, and annealing and stress relief treatment are carried out to ensure the stability of the bed.

The rear bed adopts a connecting structure layout, which effectively improves the force-bearing characteristics while being lightweight, ensuring beauty, no sheet metal required, and simple and elegant.

The best choices show their value over time

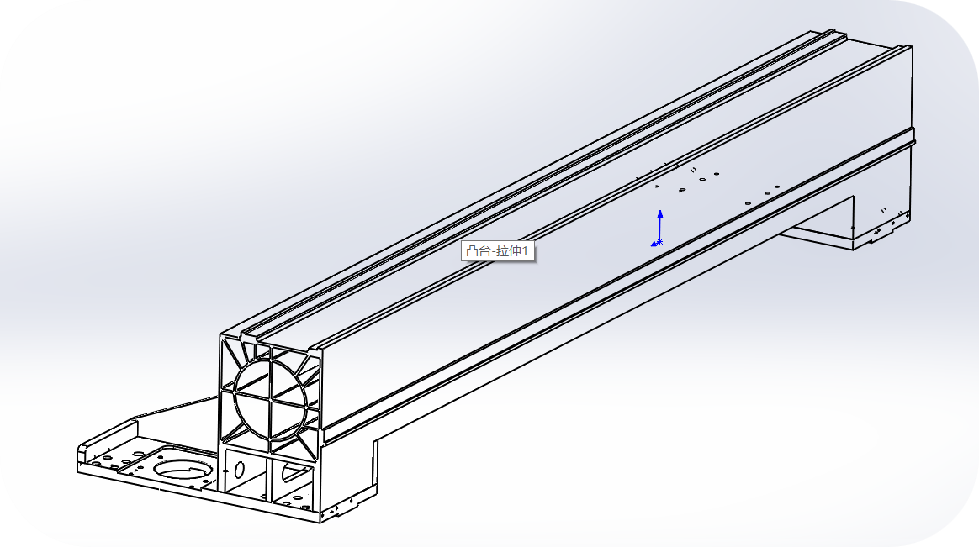

The crossbeam is made of aviation-grade high-strength aluminum alloy, and the extruded aluminum profile structure adopts an outer square and inner circle + cross-partitioned composite structure. While being lightweight, each stress-bearing surface is individually provided with reinforcing ribs to extremely enhance the dynamic response of motion.

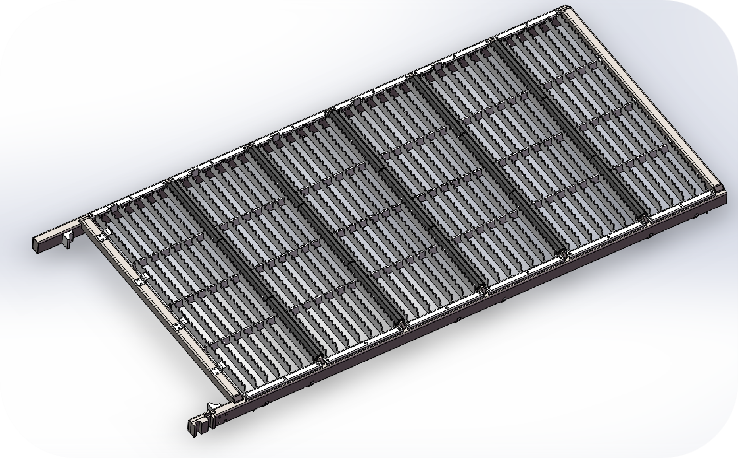

Table frame assembly:

Modular arrangement of knife bars;

Staggered arrangement of knife tips, providing effective three-point support;

High-power anti-burning cast iron bars, which increase service life and facilitate slag cleaning.

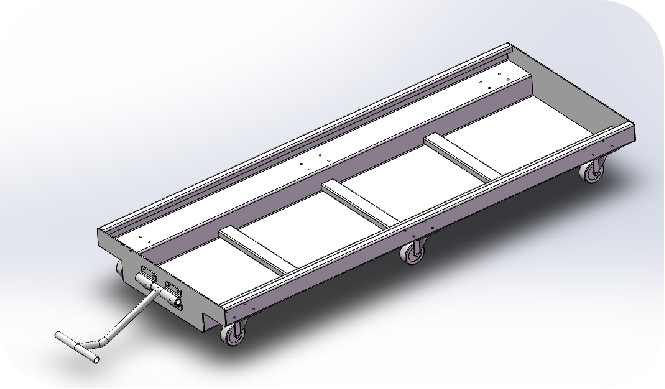

Lifting of the material cart:

The handle adopts a T-shaped mechanism, which is easy to push and pull with both hands, and is warped upward at the same time, which is convenient for workers to quickly get started;

The main structure of the box adopts an inverted “J” bend + horizontal channel steel design, which can effectively strengthen the structure and reduce thermal deformation;

The bed is equipped with a guide structure + limit baffle, which is easy to push and pull the material cart

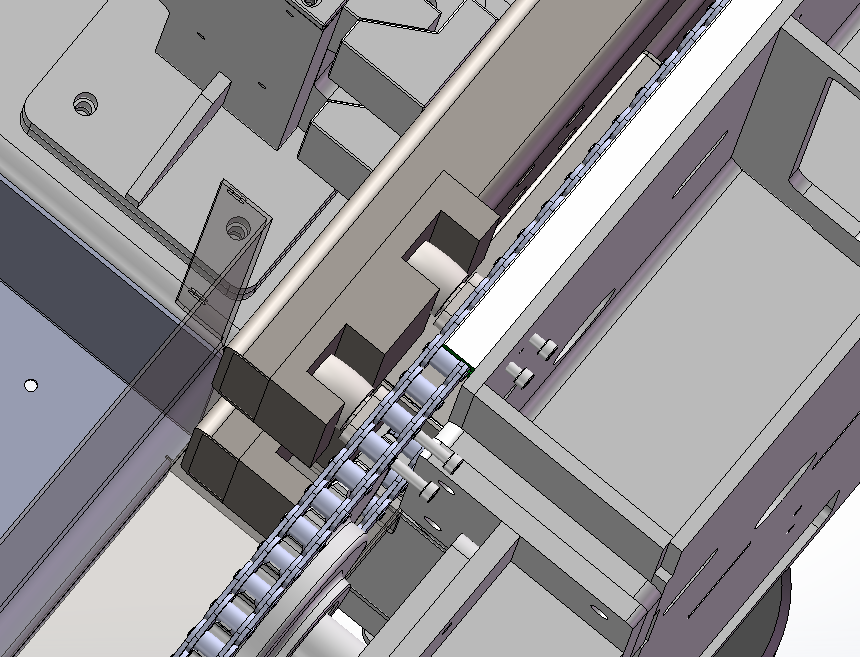

Table frame locking and transmission optimization:

Using 2 high-rigidity gate locks;

The transmission adopts a double transmission shaft design to ensure effective torque transmission;

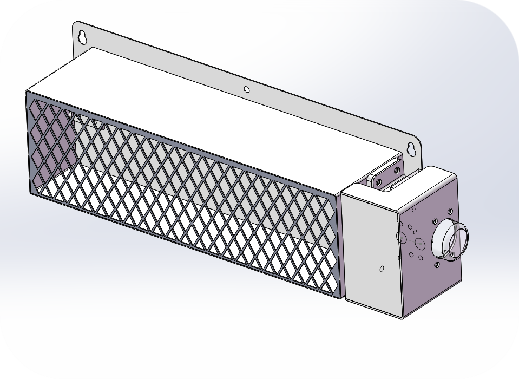

Design of flue:

The size of the partition dust removal opening is 120*400mm, and the ventilation area is +30%;

The flap valve is replaced, and the design without partition greatly reduces the wind resistance coefficient;

An L-shaped galvanized air duct is set on the back side of the bed, and the air duct outlet is set on the right rear side of the front bed, which is convenient for on-site installation.

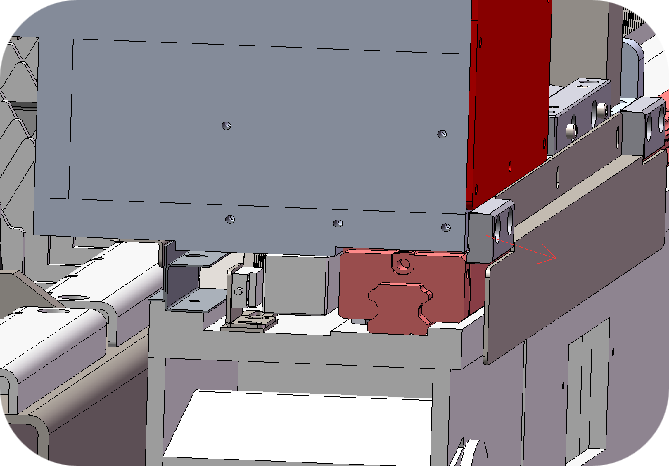

Optimization of beam fixing method:

The original beam and slider were only connected by screws, without positioning design. V2.0 adds positioning and adopts fixed + floating positioning method to ensure the stability of high-speed movement.

Optimization of the Z-axis machine head:

The laser head connecting plate is thicker, has reinforcement ribs, and has optimized weight;

The sheet metal has added heat dissipation holes for the motor and electrical proportional valve;

The Z-axis has added volumetric quantitative lubrication.

Improved sheet metal protection:

The external sheet metal is sealed with the bed and all parts to separate the entire cutting area from the outside;

The rear side uses a contoured sheet metal lifting door to reduce the area of fireproof cloth, effectively prevent light leakage and increase service life;

Fiber optic plug-in-free design.

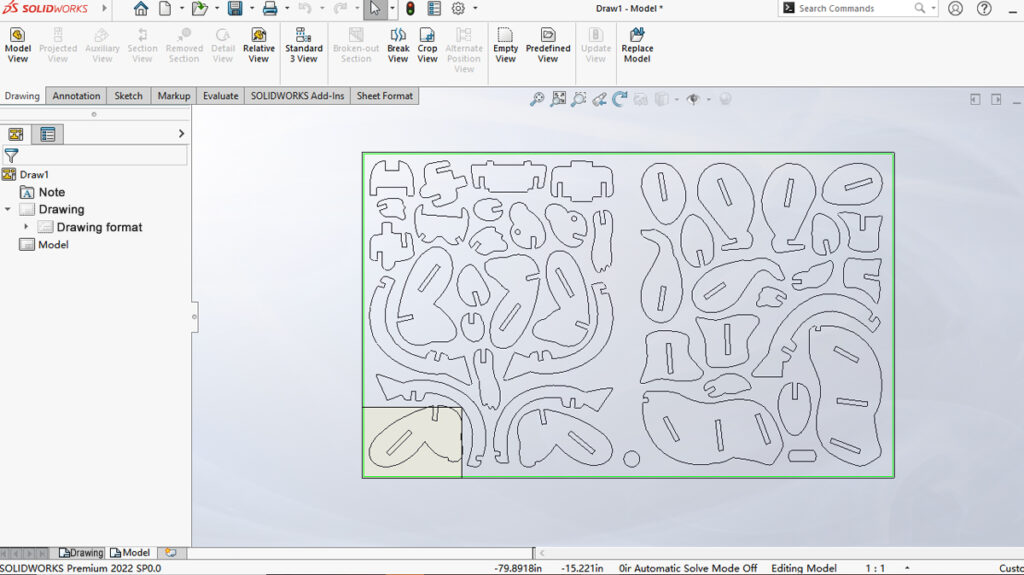

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Laser plate.

Libraries of functions that speed up and simplify design on the plate.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.