In the forging industry, laser cutting technology has been widely used in the flash and skin of structural steel and stainless steel forgings, while laser cutting technology on titanium alloy forgings is still a banned or restricted process in China. However, with the rapid development of laser cutting equipment, the improvement of laser equipment power and the diversification of laser cutting atmosphere have provided basic support for the high-quality application of laser cutting titanium alloy forgings. Therefore, the application research of laser cutting technology on titanium alloy forgings is more meaningful.

Application research on laser cutting of titanium alloy under 3000W power and O2-assisted conditions

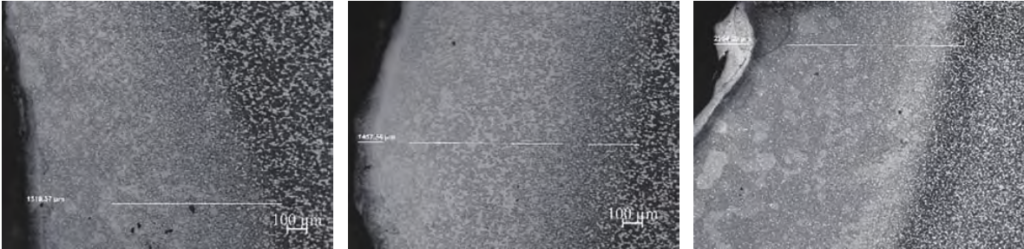

The macro morphology of the cutting surface of the sample with different thicknesses cut by laser under 3000W power and O2-assisted conditions is shown in the figure, and the corresponding microstructure is shown in the figure. From the perspective of its macro and microstructure, the cutting surface of laser-cut titanium alloy forgings under these conditions is uneven and oxidized, and the degree of unevenness of the cutting surface and the thickness of the heat-affected layer increase with the increase in cutting thickness. This is consistent with the titanium alloy. The poor thermal conductivity is related to its easy reaction with O2. While O2 cools the laser lens and nozzle, titanium alloy undergoes a violent oxidation reaction with O2 and releases a large amount of heat. Due to the poor thermal conductivity of titanium alloy, heat is difficult to diffuse and accumulates, resulting in uneven oxidation results on the cutting surface. O2 plays a role in A certain combustion-supporting effect makes the laser emit dazzling white light during the cutting process, and because of the combustion-supporting effect, it does not suffer from insufficient cutting power and is difficult to cut during the cutting process, and the cutting thickness can be unlimited. However, as the thickness of the cutting forging increases, the degree of oxidation increases significantly.

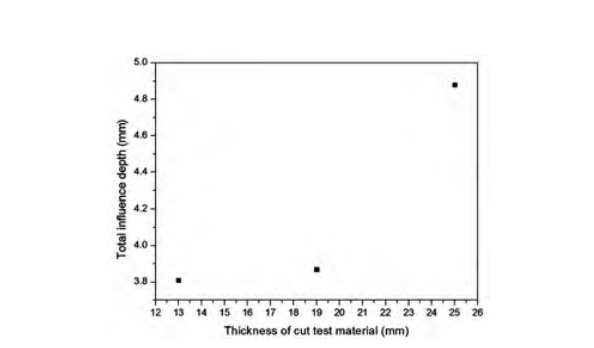

The surface of titanium alloy forgings cut by laser under 3000W power and O2-assisted conditions is compared with the heat-affected layer depth through the metallographic structure as shown in the figure. Combined with the depth results of the influence of oxidation bumps during the cutting process, the total influence depth of cutting under different thicknesses (total influence depth) is calculated. Including heat-affected layer and oxidation pit depth) The results are shown in the figure. It can be seen from the figure that when the thickness of the cutting specimen increases from 13mm to 25mm, the total depth of influence increases from 3.81mm to 4.88mm. This depth of influence has exceeded the design margin of the forging. During the flash cutting and joining of the forging, It is not suitable for leather cutting and rough processing.

Conclusione

Laser cutting titanium alloy forgings under 3000W power and O2-assisted conditions. Because titanium and O2 are prone to chemical reactions and O2 has a combustion-supporting effect, thicker titanium alloy forgings can be cut, but there will be obvious unevenness and heat-affected layer on the cutting surface. Thicker, when the thickness of the sample increases from 13mm to 25mm, the total depth of influence increases from 3.81mm to 4.88mm, (a) 1# sample (b) 2# sample (c) 3# sample Figure 7 Laser cutting The influence depth of the heat-affected layer morphology of samples with different thicknesses has exceeded the design margin of forgings and does not meet the conditions for popularization and application.

With the development of laser technology, higher-power laser equipment is constantly being developed, and the application of inert auxiliary gases is becoming more diversified. High-power, inert gas-assisted laser equipment has shown obvious efficiency when used in the processing of titanium alloy forgings. , cost and environmental protection advantages. The “forbidden and restricted use” restrictions of laser cutting technology on titanium alloy forging processing will also be relaxed with the development of laser technology.