metal laser cutting machine

Product category introduction

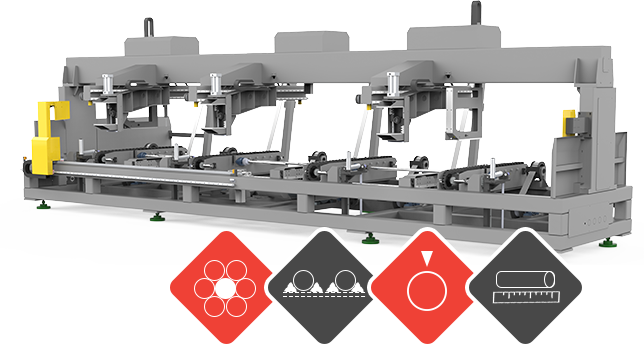

CNC metal laser cutting machine

A metal laser cutting machine is a powerful machine that can quickly and easily cut through metal. There are many different types of metal laser cutting machines, but they all work by using a high-powered laser to cut through the metal. The laser is focused onto the metal, and the machine then uses a high-speed cutting head to quickly cut through the metal. Metal laser cutting machines are used in a variety of industries, including aerospace, automotive, construction, and more. They are an essential part of the manufacturing process for many products. Metal laser cutting machines are fast, accurate, and can handle large quantities of material.

Metal laser cutting advantages

Zero tail material

Three-point clamping for long material cuts, prevents fluttering and guarantees cutting accuracy. Zero tailing is possible when the workpiece length is ≥ 460 mm

·Possibility to set the drawing position for different lengths of parts

·Cyclic drawing is also possible

·Automatic recognition of the lower position

Fast Speed

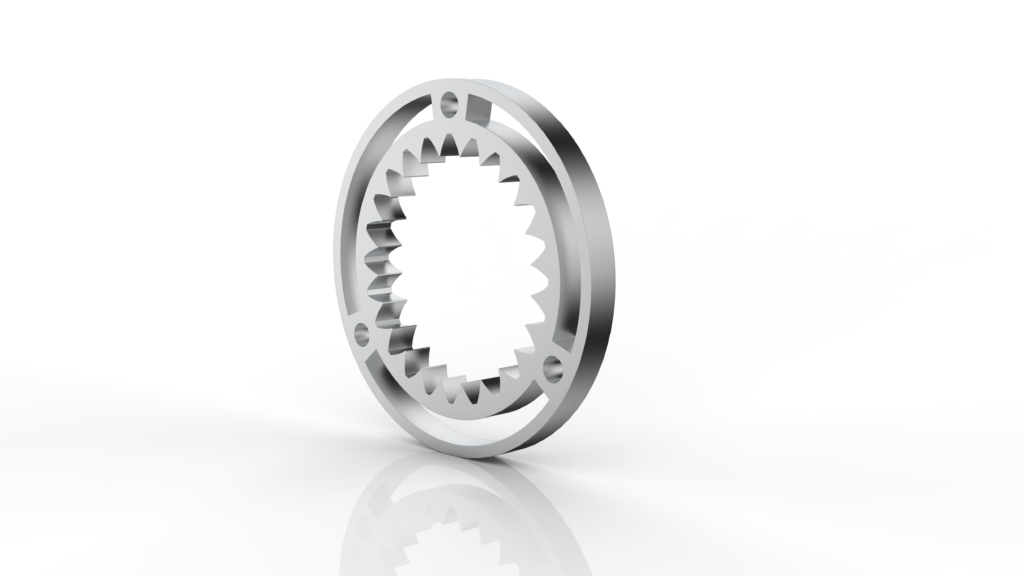

Precision small chucks

·Rotary motor with 3 kW power

·With helical gearing, the chuck speed is 150 rpm/min

·Up to 200 rpm/min

Fully automatic loading

No need for manual

·intervention, saves time and effort

·Automatic loading of short and long materials from 4-6.2M

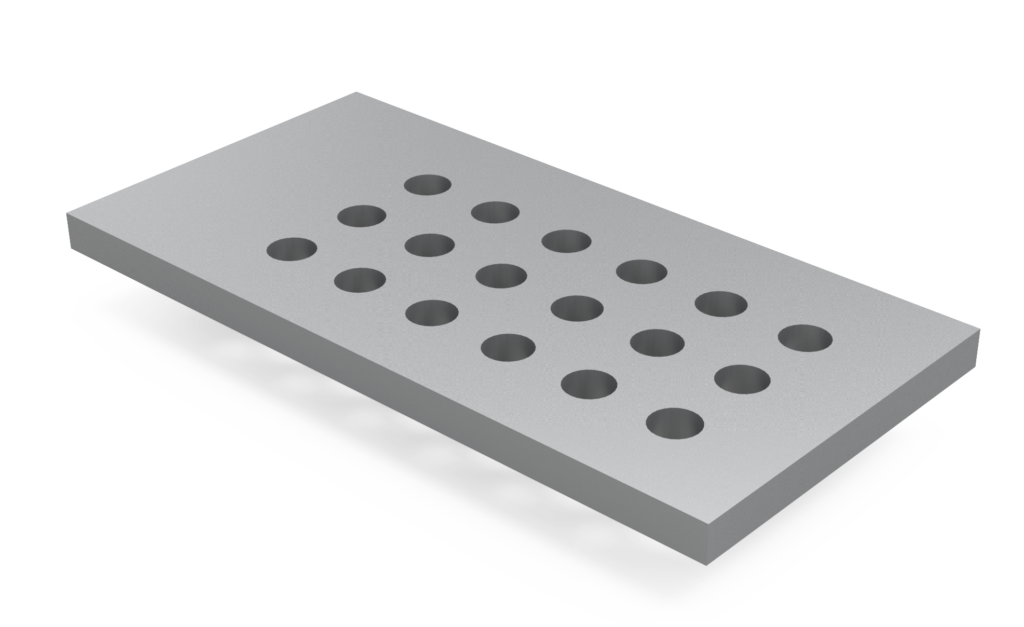

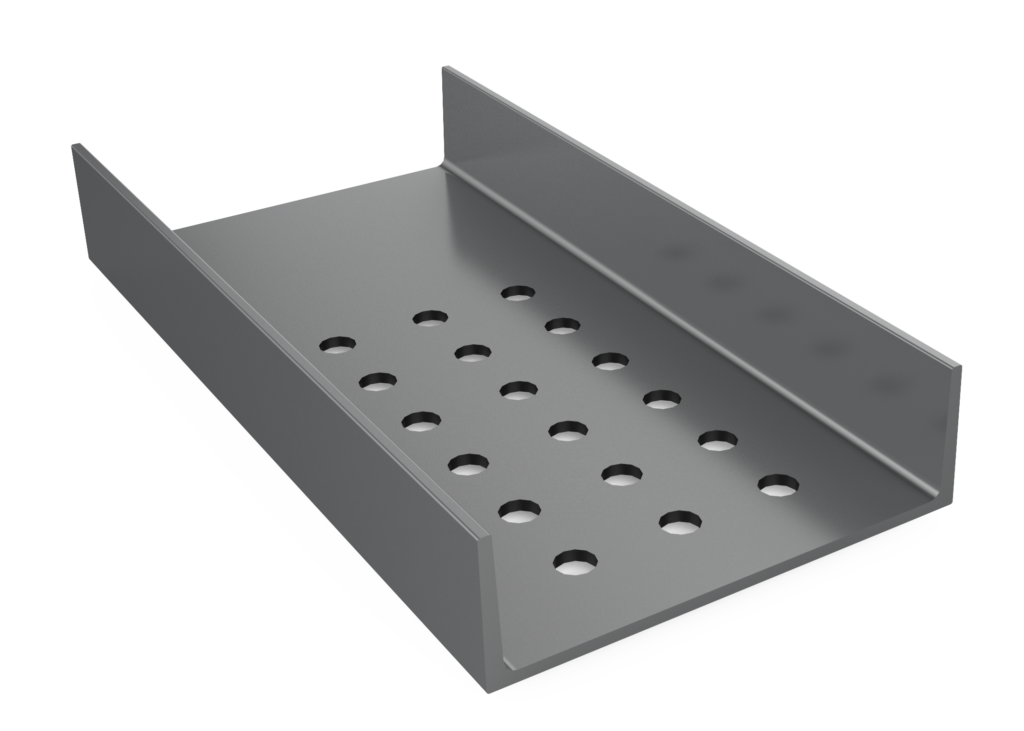

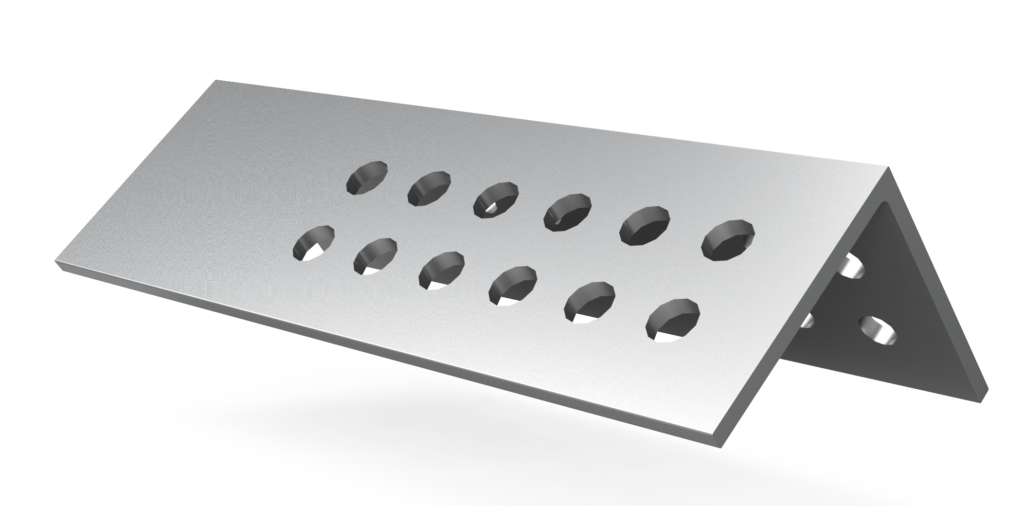

·20-200dia multi-tube round, square and rectangular tubes

Large load, storage rack with a capacity of 2 tons

100kg for a single tube

Efficient smoke extraction

The system coordinates the laser cutting head with the whole machine, identifying the area at the front, middle and rear of the machine where the laser head is working, then the fume extraction holes in that working area will open.

The pressure of the fan at the top of the machine and the suction of the fan at the back of the machine exhausts the smoke in real time during the cutting process. This speeds up the smoke exhaust and enhances the air circulation inside the machine, making the smoke exhaust more complete.

Technical Parameters

| Maximum cutting length | Material 6000-12000mm, unloading piece 0-8000mm |

| Maximum weight for each tube | 4000kg |

| Cutting diameter | 15-650mm O.D. |

| Rotary speed | 60-180rpm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Minimum tailing | 0mm |

| Maximum running speed | 100m/min |

| Power supply | 380V/50Hz |

| Working area | 12000*3000mm |

| X-axis travel | 1520-3050mm |

| Y-axis travel | 3020-12050mm |

| Z-axis travel | 120-300mm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Acceleration | 1-2.5G |

| Maximum running speed | 150m/min |

| Maximum table loading weight | 7000kg |

| Laser power | 12000W-30000W |

| Power supply | 380V/50Hz |

Application Field

Laser cutting machines have been around for decades, but their use in the metal industry is relatively new. Metal laser cutting machines are used to cut metal faster and more accurately than traditional methods, making them an essential piece of equipment for any metal shop.There are many different types of metal laser cutting machines on the market, each with its own unique capabilities. Some laser cutting machines are designed for specific metals, while others can cut a variety of different metals.No matter what type of metal you need to cut, there is a laser cutting machine that can do the job. If you’re looking for a fast, accurate way to cut metal, a laser cutting machine is the way to go.

Technology and ability to design machinery

JQ Laser has the technology and ability to design machinery. The company has years of production experience, which gives it an edge over its competitors. Besides, This is based on the company’s extensive experience in designing and manufacturing laser machines. In addition, JQ Laser constantly collects feedback from customers, which helps them improve their products. As a result, the company is able to offer its customers high-quality machines that meet their needs.Third, because the company has a lot of capital for independent research and development. The company also has a lot of experience in the industry. Finally its due to their affection for the laser cutting industry. They have a strong team that is able to develop new products quickly and efficiently. In addition, their customer service is excellent and they are always available to help with any issues that may arise.

What we offer is different

As a company that has been in the industry for over 10 years, we have had the opportunity to perfect our craft. In that time, we have become experts in tube laser cutting machines. This allows us to offer our clients a unique advantage—the ability to produce high quality products with a quick turnaround time.

Our team of skilled professionals are able to operate the machines quickly and efficiently, meaning that your project can be completed in a shorter timeframe than if you were to use another company. Additionally, because we have such a high level of experience, we are able to offer competitive pricing without compromising on quality.

If you are looking for a company that can provide you with the best possible service and product, then look no further than us. We guarantee that you will be satisfied with the final product and amazed at how quickly it was completed.

Installation guide and after sale service

JQ Laser provides complete user guidance on installation and use, which has set up a special overseas after-sales department to solve all user problems in a timely manner.The company has been committed to providing users with the best products and services, and has always been highly praised by users. The establishment of the overseas after-sales service department will further enhance the company’s service level and better protect the interests of users.and has successfully helped customers in more than 170 countries and regions to achieve normal operation. JQ Laser will continue to provide users with better products and services, and create more value for users.

JQ Laser has always been proud of its efficient after-sales service and problem solving. We have a team of highly trained and experienced staff who are always ready to help our customers with any issues they may have. We also offer a satisfaction guarantee so that our customers know that they can always expect the best from us.

Order process

In just a few simple steps

During the communication, the salesperson will recommend products and quotes according to your needs.

After placing an order, you will always be provided with product production and logistics information.

After receiving the goods, you will get complete written and online instructions, 24 hours after-sales service.

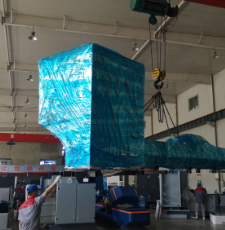

Saving Your Shipping Cost

JQ Laser is the top leader in research and development as well as production capacity in the laser industry. They always consider customer service to be a priority.There are many factors to consider when deciding on the packing size for shipping crates. The most important factor is the safety of the items being shipped. The second factor is the cost of shipping. You want to make sure that you are getting the most bang for your buck when it comes to shipping costs.We take all of these factors into consideration when we design shipping crates for our clients. We analyze the items to be shipped and determine the best packing size that will ensure their safety during transport. We also work with our clients to maximize their logistics cost so they can save money on shipping.Our years of experience and expertise allow us to provide our clients with the best possible packing solution for their needs. Contact us today to see how we can help you with your next shipment.

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

People Also Ask

What laser cutters can cut metal?

6,000-watt lasers are particularly effective for cutting through thick or strong metals, though lower-wattage lasers are quite often good enough to get the job done.

Can a 40 watt laser cut metal?

A 40-watted laser isn’t the best option for cutting metal. If you possess a 40-watt laser machine, you can only partially use it on materials such as acrylic.

What kind of laser cutter can cut metal?

Among the most typical laser wattages to examine are 3,500, 4,000, and 6,000. Lasers of 6,000 watts are very effective for cutting through specifically thick or strong metals, although they often require a lower wattage.

What is the best laser for cutting metal?

An industrial fiber laser with a power rating of over 20W is ideal for etching or marking a variety of metals, whereas a laser with a power rating of over 100W is superb for cutting jobs.

Leave Message And Get The Answer

In order to improve the user experience and improve our production technology, JQ laser has been collecting real machinery handling questions and comments from the market, which we will analyze and provide answers to, and we will also adopt the favorable production ideas.