Surface optimization method for laser sheet cutting is an advanced technique that enhances cutting efficiency and quality in various industrial applications. With the ever-evolving demands of precision manufacturing, the adaptation of surface optimization methods has become essential in achieving optimal results and maintaining competitive advantage in the market.

Surface optimization methods for laser sheet cutting involve various techniques and technologies designed to improve surface quality while minimizing material waste. The process typically entails the adjustment of cutting parameters, material properties, and machine conditions to enhance the overall performance of the laser cutting process. This is particularly crucial in applications such as aerospace, automotive, and electronics manufacturing, where high accuracy and surface finish are critical. The main objectives of surface optimization in laser sheet cutting include:

- Minimizing Burr Formation: Burrs can significantly impact the fit and function of components, and various optimization techniques can help reduce their occurrence.

- Improving Edge Quality: High-quality edge finishes enhance the overall performance of components and reduce the need for additional secondary processing.

- Enhancing Material Utilization: Optimized cutting parameters can help minimize waste, leading to increased efficiency and cost savings.

Comparison of Surface Optimization Techniques

| Technique | Advantages | Disadvantages |

|---|---|---|

| Adaptive Cutting | Real-time adjustments, improved accuracy | Requires advanced sensors and algorithms |

| Pulse Modulation | Enhanced control over heat input | Complexity in implementation |

| Nitriding | Increases surface hardness for durability | Requires additional treatments |

| Adjustable Focus Lens | Better focus management for various materials | Can be costly |

In addition to the techniques, the equipment used in laser sheet cutting must also be optimized for performance. This includes the selection of lasers with appropriate power ratings, focusing optics, and motion systems that can handle the specific requirements of the chosen material and cutting thickness.The surface optimization method for laser sheet cutting also integrates software solutions that aid in designing cutting paths and predicting potential errors during the cutting process. CAD/CAM software enables manufacturers to simulate cutting processes, allowing for adjustments before actual cutting. This preemptive strategy can save time and resources while also ensuring high-quality output.As the industry continues to grow, further innovations in surface optimization methods for laser sheet cutting are anticipated. Advanced algorithms, real-time monitoring, and feedback systems may soon lead to fully automated and optimized cutting processes, setting new benchmarks for quality and efficiency in manufacturing.

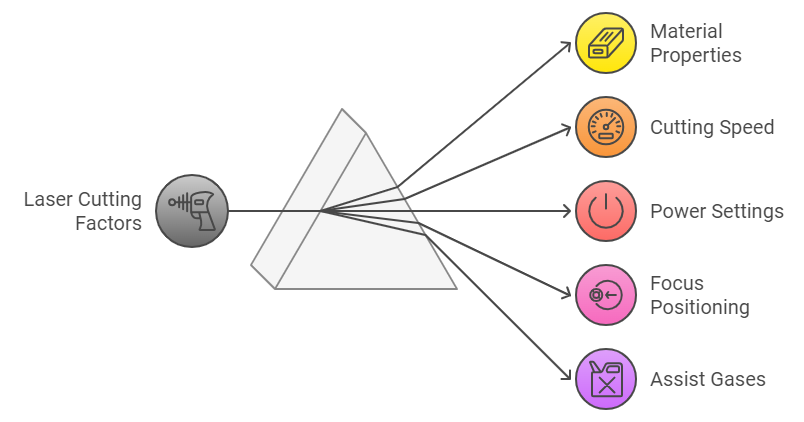

Key Factors Influencing Surface Optimization

- Material Properties: Different materials respond uniquely to laser cutting due to their inherent characteristics such as thickness, density, and thermal conductivity. Understanding these properties allows manufacturers to tailor their optimization strategies effectively. For instance, metals may require different settings compared to plastics or composites.

- Cutting Speed: Adjusting speed can significantly affect heat input and cut quality. Faster speeds may reduce heat-affected zones but could increase burr formation if not managed properly. Finding the right balance is essential for achieving optimal results without compromising quality.

- Laser Power Settings: Properly calibrating power settings is crucial for achieving desired cut depths without compromising edge quality. Higher power levels might be necessary for thicker materials but could lead to excessive heat input if not controlled effectively.

- Focus Positioning: The focal point of the laser beam must be accurately positioned to ensure optimal energy concentration on the material surface. An incorrect focus can lead to poor cut quality or even damage to sensitive materials.

- Assist Gases: The choice of assist gases (like oxygen or nitrogen) influences oxidation levels during cutting and can enhance cut quality by improving heat dissipation. Selecting the right gas based on material type can significantly impact overall results.

Advanced Techniques in Surface Optimization

- Machine Learning Algorithms: Utilizing AI to analyze historical data can lead to predictive adjustments that enhance cutting performance dynamically. By learning from past outcomes, these algorithms can recommend optimal settings that minimize waste while maximizing efficiency.

- Real-time Monitoring Systems: Implementing sensors that provide immediate feedback on cut quality allows operators to make real-time adjustments during production runs. This capability ensures that any deviations from expected outcomes are addressed promptly, maintaining high standards throughout the process.

- Hybrid Cutting Techniques: Combining traditional methods with laser technology can optimize results by leveraging strengths from both approaches. For example, using mechanical methods alongside lasers can enhance precision while reducing thermal effects on sensitive materials.

Industry Applications

Surface optimization methods are widely applicable across various sectors:

- Aerospace Industry: Precision is paramount; therefore, optimizing surfaces ensures safety and reliability in components like fuselage sections and engine parts.

- Automotive Manufacturing: High-volume production requires efficient processes; optimized laser cutting reduces waste while maintaining quality standards.

- Electronics Sector: Delicate materials necessitate careful handling; surface optimization helps achieve intricate designs without damaging components.

Challenges in Implementation

While surface optimization methods offer numerous benefits, several challenges persist:

- Cost of Equipment Upgrades: Investing in advanced machinery may be a barrier for smaller manufacturers who may lack the capital needed to upgrade their existing systems effectively.

- Training Requirements: Skilled personnel are needed to operate sophisticated systems effectively; without proper training programs in place, companies may struggle with maximizing their investment in new technologies.

- Integration with Existing Systems: Ensuring compatibility between new technologies and legacy systems can complicate implementation efforts; this often requires additional resources or expertise that may not be readily available within an organization.

Achieving Perfection: The Science Behind Surface Optimization for Laser Sheet Cutting

Achieving perfection in laser cutting requires a deep understanding of the science behind surface optimization methods. Factors such as beam intensity distribution, pulse duration, and material thermal conductivity all play critical roles in determining cut quality. By employing simulation tools and predictive modeling, engineers can anticipate how different settings will affect the final outcome. This scientific approach allows for precise control over the cutting process, leading to consistent results that meet or exceed industry standards.

Future Trends

The future of surface optimization methods for laser sheet cutting looks promising:

- Increased Automation: As automation technology advances, fully automated systems will likely become standard in manufacturing environments where speed and precision are critical.

- Sustainability Focus: Eco-friendly practices will drive innovations aimed at reducing waste during production processes; manufacturers will increasingly seek solutions that align with global sustainability goals.

- Customization Capabilities: Tailored solutions based on specific industry needs will become more prevalent as technology evolves; this adaptability will allow companies to meet diverse customer demands efficiently while maintaining high-quality standards.

Conclusione

The evolution of surface optimization methods for laser sheet cutting represents a critical advancement in manufacturing technology. By focusing on enhancing efficiency, reducing waste, and improving product quality, these methods not only meet current industry demands but also pave the way for future innovations that will further transform manufacturing practices across various sectors.As companies continue to invest in these technologies, we can expect significant improvements in productivity and sustainability within the industry.