Energia eolica

Laser cutting is a technology that has been around for decades, but it is only now being leveraged in the wind power industry. With our company’s extensive industry expertise, we are able to help this rapidly growing industry take advantage of laser cutting technology.

Laser cutting offers many advantages over traditional machining methods, including higher precision, cleaner cuts, and less material waste. This makes it an ideal technology for use in the wind power industry, where precision and efficiency are key.

Our team has years of experience working with laser cutting technology, and we are passionate about helping our clients succeed. We are proud to be able to help the wind power industry grow rapidly by leveraging this powerful technology.

a versatile technology

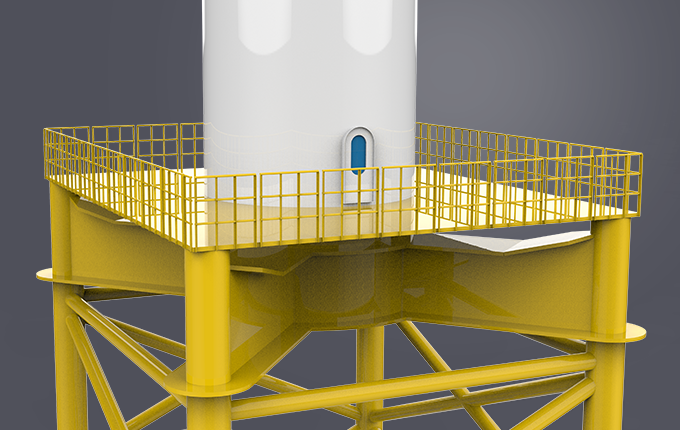

Laser cutting is a versatile technology that can be used in a variety of industries. In the wind power industry, taglio laser can help with the fabrication of turbine blades, the assembly of nacelle components, and the installation of turbine towers.

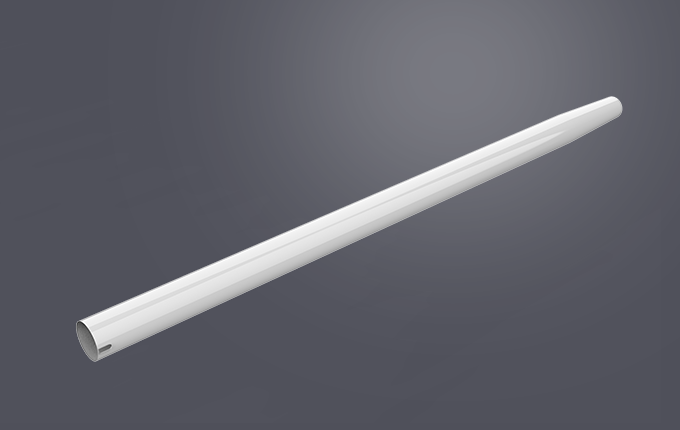

ideal method for fabricating turbine blades

Laser cutting is an ideal method for fabricating turbine blades because it can create complex shapes with precise tolerances. Additionally, laser cutting can be used to cut multiple pieces at once, which helps to improve production efficiency.

Assembly of nacelle components

Assembly of nacelle components is another area where laser cutting can be helpful. Lasers can be used to cut and drill holes for mounting brackets and other hardware. Additionally, lasers can be used to cut cable trays and other electrical enclosures to custom sizes.