Design of a flexible production line system for plate laser cutting

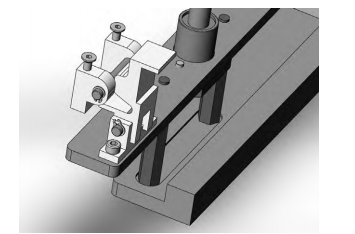

In order to improve the consistency and yield rate of products after laser cutting, it is necessary to accurately position the plates that are loaded during cutting. However, because wooden boards have a certain degree of elasticity and have large dimensional errors and are easily deformed, and the boards are stacked at random positions in the loading bin, pre-positioning is required before processing and clamping to ensure the positioning accuracy of the right-angle origin of the square boards ( (Reduce the error between workpiece coordinates and processing coordinates) and then use the robot suction cup to grab and transport it to the laser cutting machine processing area. After the loading […]