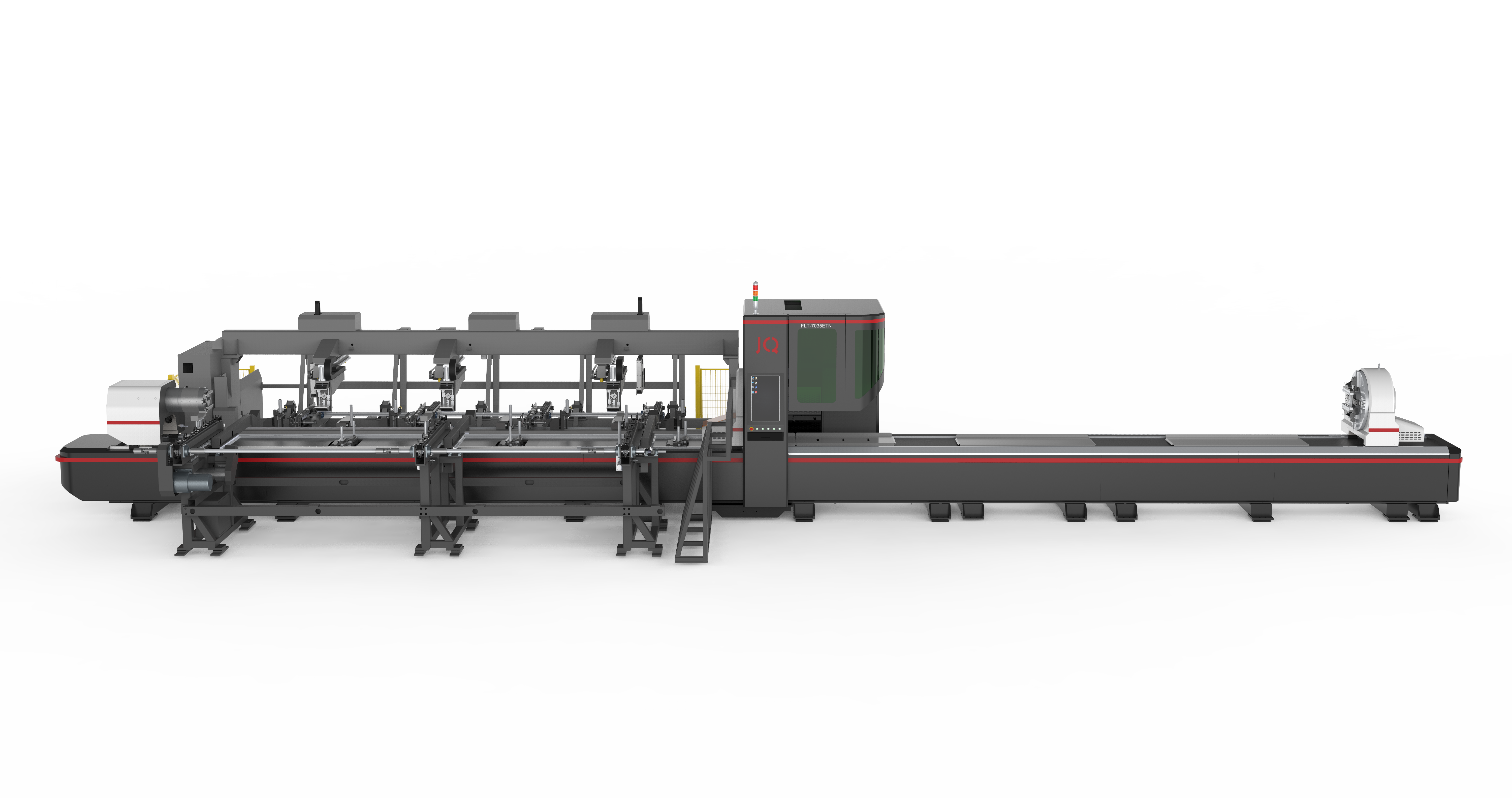

FLT-7035ET

Start off on the right foot

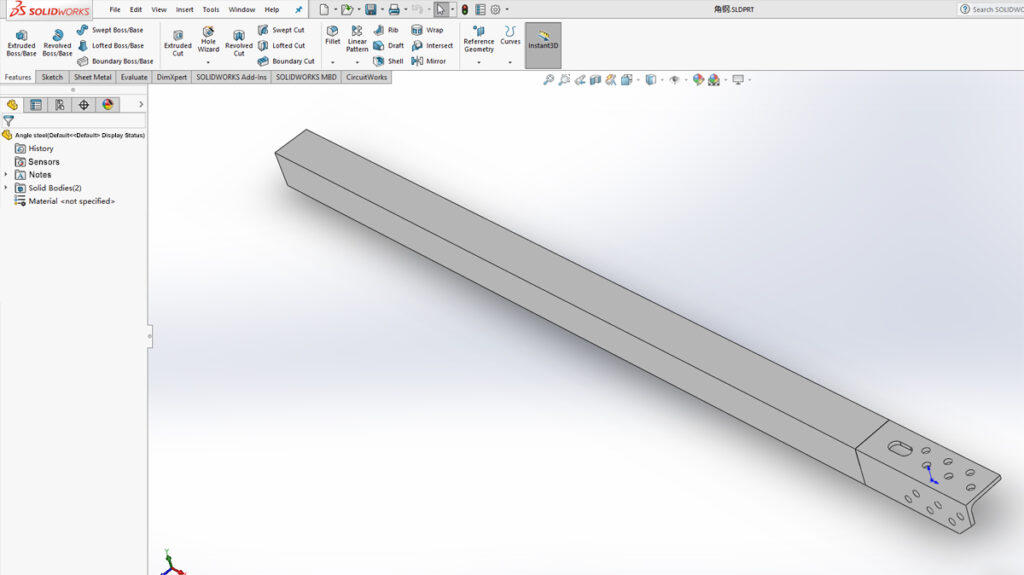

Round, square,

rectangular tubes

500 kg

(15 to 350 mm)

The best of technology in the smallest member of the family

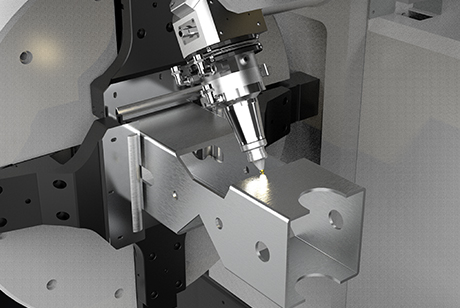

Experience superior part production with the advanced TubeCutter cutting head integrated into the FLT-7035ET. Effortlessly create high-quality components thanks to its automatic focus and seamless laser parameter management, eliminating the need for manual adjustments.

Performance based on robustness and, above all, reliability.

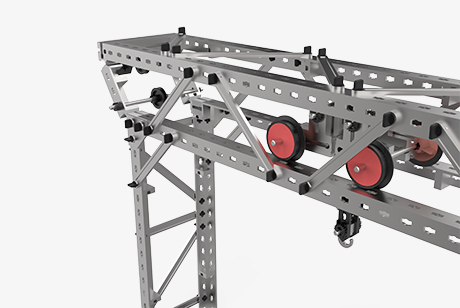

Ergonomic and accessible

1. Zero Tailings

2. Servo follow-up support, Support Anti Bending System

3. Servo unloader: Long unloading work piece: 6m,9m, 12m

4. Tube diameter range:From 15 to 350mm

5. Round, square, rectangle, special sections and open profiles.

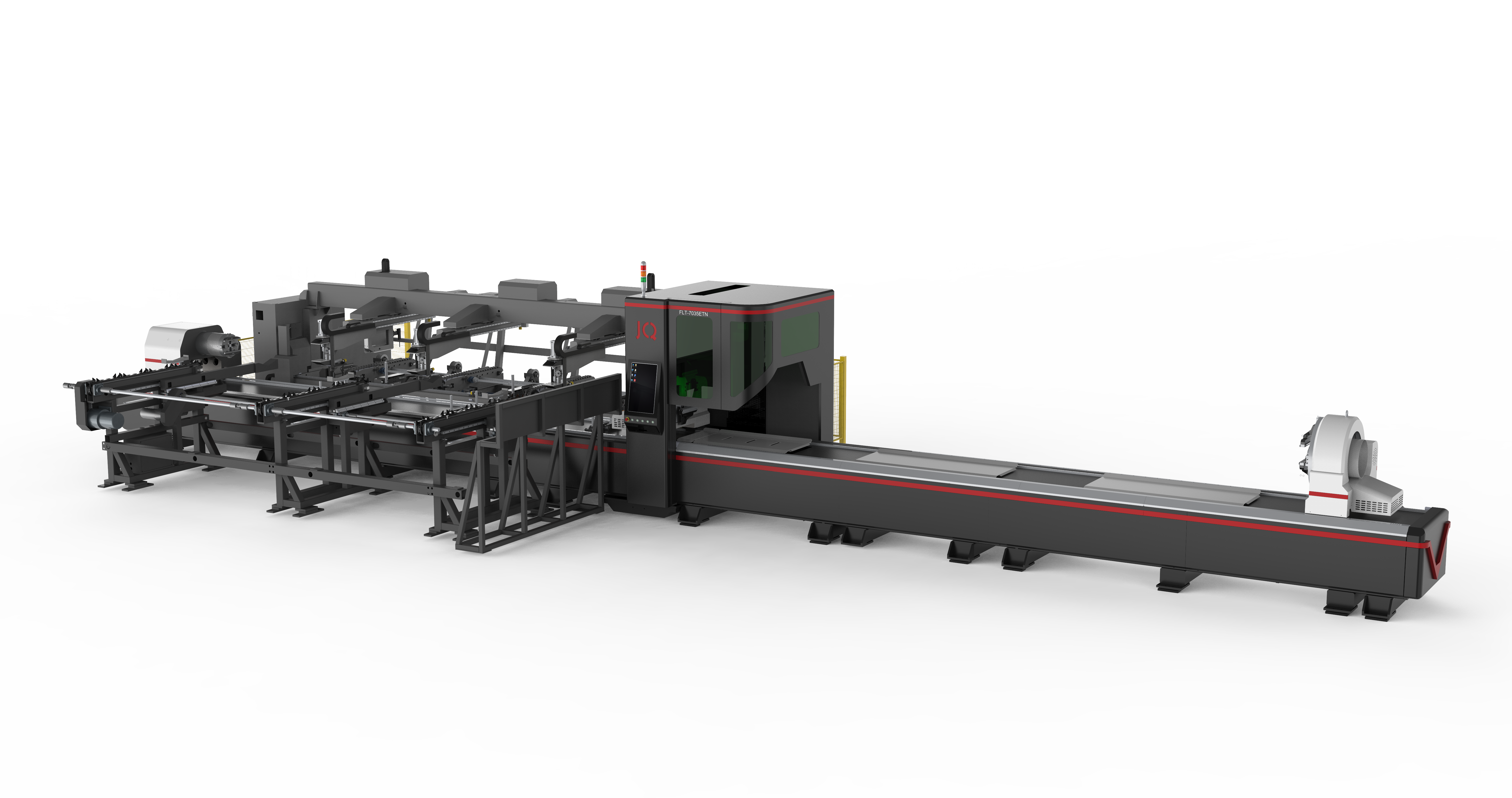

Form and content in a single solution

The best choices show their value over time

When selecting a laser cutter for cutting thick or slightly flexible materials, ensure the laser source aligns with the material’s thickness and the intricacy of the task. Loading small, flexible tubes should be effortless, while thicker, heavier parts might pose challenges during the process.

Machine performance will remain robust, reliable and productive year after year.

The software suite that creates value

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.