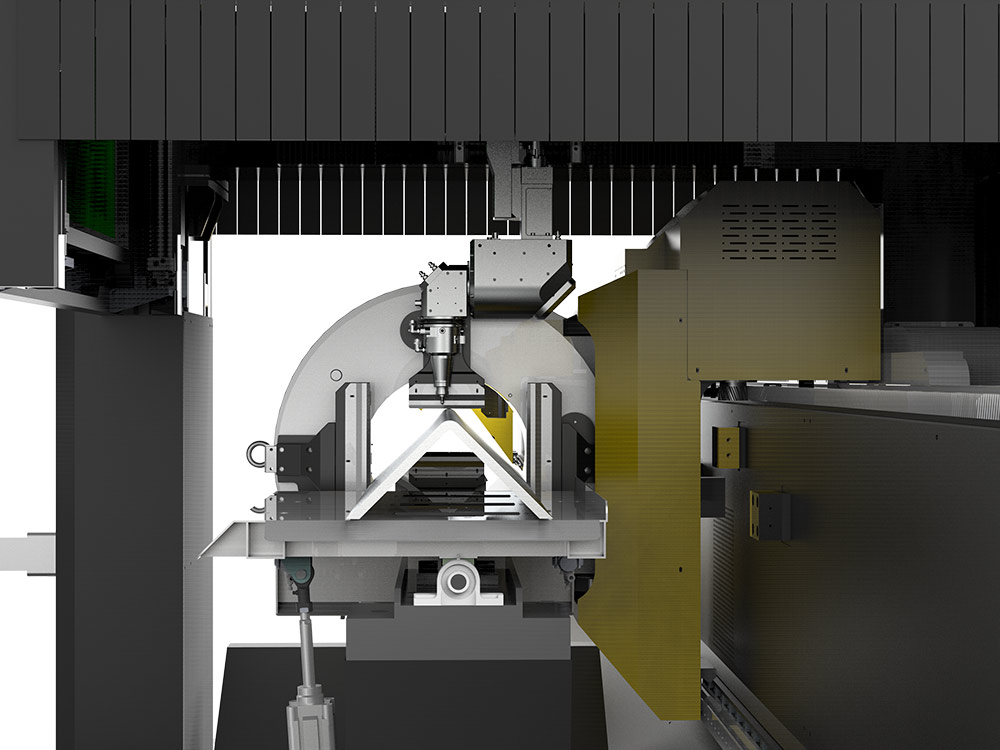

New Product JQ Vertical Three Chucks Series

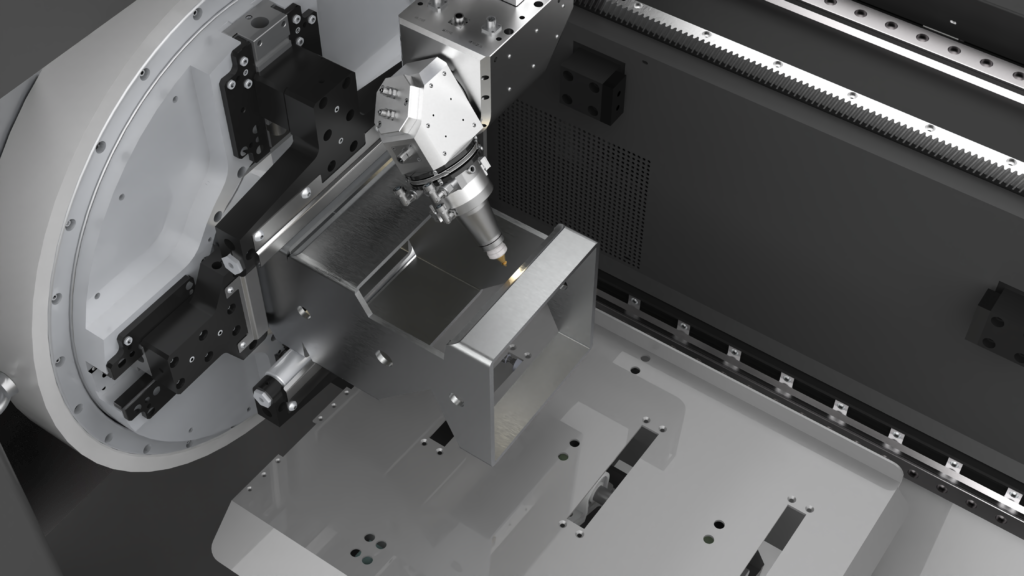

FLT-7028HTS automatic feeding three-chuck CNC laser pipe cutting machine Product Features Overview The bed and chuck adopt a side-mounted connection design to facilitate the loading and unloading of large-diameter pipes.The bed is made of square tubes with a wall thickness of 8~10mm and steel plates ranging from 40mm to 20mm, and is welded together. It is divided into 3 sections and connected by high-strength bolts and positioning keys to ensure geometric accuracy after connection. After welding, it is annealed to eliminate internal stress. After rough machining, vibration aging is performed and then fine machining is performed. This greatly improves the rigidity and stability of the machine tool and ensures the […]

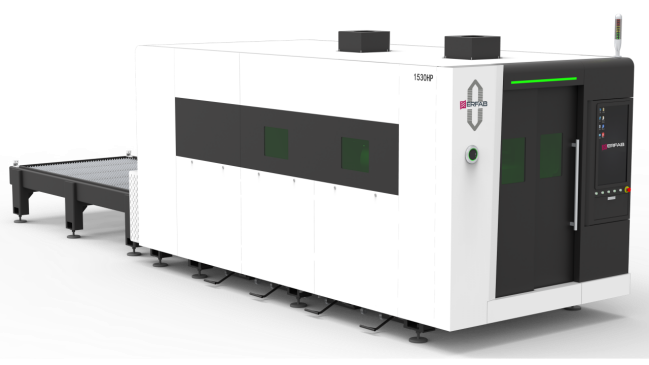

JQ Laser Introduces Upgrades to 1530HP Laser Cutting Machine

Main Features √ Heavy duty machine base. √ High power servo motors. √ Smart cutting control system, easy operation; √ Quick piecing, supported by segment and step piecing technology; √ Specialized air duct with out sized caliber, makes smoke exhaust smooth. √ Fully enclosed design; √ European CE Standard laser protection. √ Dual shuttle tables provides high level of safety and convenience. Mechanical Features: MachineBody The bed structure adopts a plate welded box frame structure, the ribs are reasonably arranged, and the key overlaps adopt a plug-in structure. Strict welding processes are formulated and annealed to remove stress and undergo aging treatment to ensure the stability of the machine bed.The machine width is 2260mm, which enables the entire container to be loaded into the container without […]

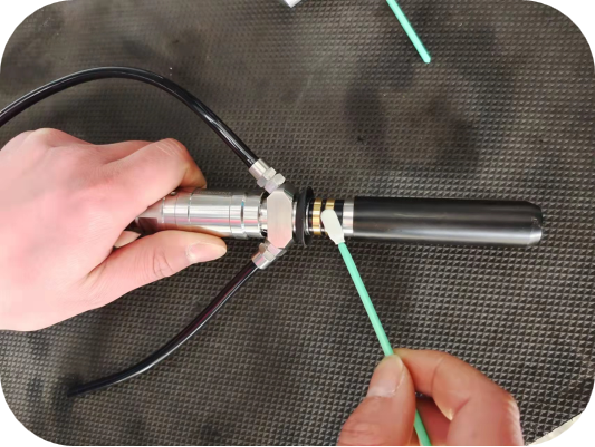

JQ CE welding machine installation instruction

Equipment installation process Host location installation Equipment installation conditions The distance between the side of the equipment and the wall is ≥0.5m, and the distance between the equipment exhaust fan and the wall is ≥1m. The operating environment of the equipment is within 0~45℃ Low humidity and relatively dry (humidity within 20%~80%, no condensation) Less dust, dust, disgust, water and other places No flammability, corrosive gas or liquid Will not receive too much impact or vibration Stay away from electromagnetic fields (TIG welding equipment, etc.) Stay away from strong magnetic fields Add water to chiller Water quality requirements:Circulating water allowed to be used by the chiller: purified water, distilled water, […]

Introduction to Tube and Plate Laser Cutting Machines

The development and widespread adoption of tube and plate laser cutting machines mark a significant technological advancement in the field of manufacturing and fabrication. These machines, embodying the latest in laser technology, have revolutionized the way industries approach material cutting, offering an unmatched blend of precision, efficiency, and versatility. This introduction delves into the intricate details of these machines, exploring their capabilities, applications, and the technological nuances that set them apart. 1. The Core Mechanism: Tube and plate laser cutting machines operate using a high-powered laser beam, which is precisely focused to a minuscule point. This intense concentration of energy serves to melt, burn, or vaporize the material it encounters. […]

What Makes Fiber Lasers Special and Expensive Compared to CO2 Lasers?

Introduction to Fiber Lasers Fiber lasers represent a significant advancement in laser technology, distinguished by their unique design and operational principles. A fiber laser uses an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, or dysprosium as its active gain medium. The design of fiber lasers allows for a high degree of beam quality and energy efficiency. The light generated in the fiber core is amplified and channeled through a flexible fiber optic cable, allowing for greater control and precision. The compact nature of fiber lasers, combined with their high electrical-to-optical efficiency, makes them a preferred choice in industries that demand high precision and efficiency. Fiber lasers […]

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN Introduction The integration of advanced laser tube cutting machines like the FLT-6035ETN into modern manufacturing processes marks a significant technological advancement. These machines epitomize precision, efficiency, and versatility in metal fabrication. However, their sophisticated nature necessitates a strategic approach to maintenance and operation to maximize their lifespan and maintain their high performance. Understanding the mechanics, features, and proper care of the FLT-6035ETN is essential for any operator or maintenance team tasked with its upkeep. Overview of FLT-6035ETN The FLT-6035ETN stands out in the world of laser cutting with its unique features and capabilities, […]

Methods to extend the service life of industrial welding machine lasers

The reason why welding machine lasers are easily damaged. The laser cutting process uses high-power and high-density laser beams to scan the surface of the workpiece and locally heat the material to thousands or even tens of thousands of degrees Celsius in a very short time, so that the irradiated material can quickly vaporize and melt. , ablate or reach the ignition point at the same time, the molten material is blown away by the high-speed airflow coaxial with the beam, so as to cut the workpiece and achieve the purpose of cutting the material. At present, the purity of compressed air in large domestic steel plants often cannot meet […]

Application of laser cutting technology in machinery manufacturing

Main types of laser cutting technology Vaporization cutting Vaporization cutting is the most widely used cutting form in laser cutting technology. The laser power density used in this cutting technology is high. Once the laser is irradiated on the mechanical workpiece, except for a few Part of it will be reflected, and most of it will be successfully absorbed and converted into heat energy, causing the surface of the workpiece to reach the boiling temperature in a short time and forming a keychain on its surface. In addition, due to surface oxidation and other effects, the absorption rate will be greatly increased, and the ejected steam will effectively take away […]

Analysis on the application of laser in modern manufacturing technology

The essence of laser cutting technology is to form a laser beam by focusing high energy to directly melt or vaporize the workpiece to be processed. At the same time, the melt or oxide is processed under the action of auxiliary gas to complete the entire cutting operation. Laser cutting technology is a very advanced mechanical manufacturing and processing technology, which plays a very important role in improving the core competitiveness and overall level of machinery manufacturing enterprises. 1 Characteristics of laser processing Laser processing was originally developed and proposed by Germany in the 1960s. Its working principle is to use lasers to form high-energy particles to directly melt or […]

Stainless steel laser cutting process optimization and surface quality research

Most items made of stainless steel are anti-corrosive, and items made of stainless steel are also processable. Therefore, stainless steel can be used in different fields, such as the aerospace industry, the medical industry, and different types of mechanical instruments. Industry, stainless steel materials are also widely used in coal mine machinery and facilities, and it is very important to choose the appropriate cutting processing method. It is difficult to guarantee the cutting quality and cutting efficiency when cutting materials with traditional cutting technology, but laser cutting technology It can make up for the shortcomings of traditional cutting technology. Laser cutting technology has the advantages of high speed and high […]