Research on the application of laser processing technology in agricultural machinery manufacturing

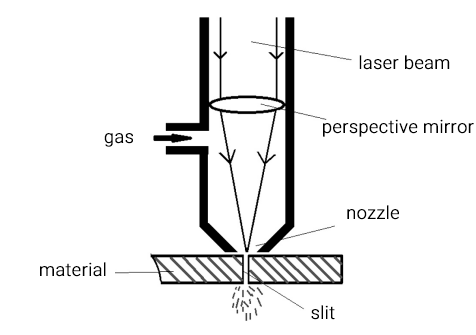

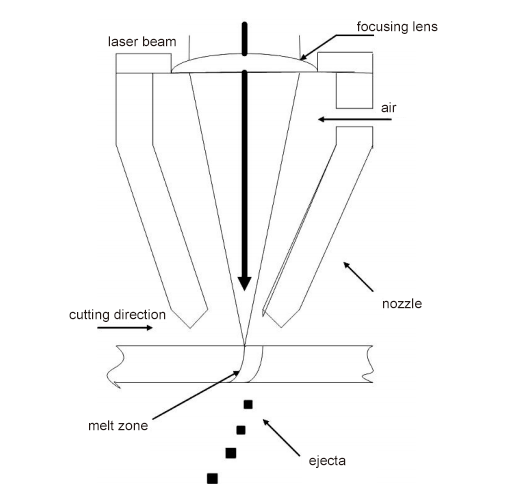

Application of laser cutting technology in agricultural machinery manufacturing Laser cutting technology applies a laser beam to the surface that needs to be processed for processing. At this time, a very high temperature will be formed on the surface to complete the processing. After the application of the laser beam, the oxidation reaction can be achieved. The steam and slag generated at this time can be directly discharged into the external space through the auxiliary gas, and then various shapes and sizes that meet the user’s requirements can be formed on the surface of the workpiece. In this way The entire processing process can be completed. In addition, laser cutting […]

Laser cutting follow-up control system

The laser cutting servo control system is a mechanical device based on motion control and capacitive sensing, including four parts: controller, capacitance detection chip, capacitance sensor, servo motor, objective lens driving mechanism and input device. The working principle is to treat the laser nozzle and the metal cutting plate as a flat capacitor, and quickly detect the capacitance value of the flat capacitor according to the detection system to adjust the distance between the laser nozzle and the plate to achieve the purpose of dynamically controlling the focal length to be constant. Keywords: laser cutting technology; follow-up control; constant focus. With the vigorous development of the manufacturing industry, traditional cutting […]

Application of laser processing technology in the manufacturing of transmission tower

Principles, characteristics and advantages of laser processing technology 1. 1 Principle of laser processing technology Laser processing is a very important high-energy beam processing method, which has the characteristics of strong laser directionality, high brightness, good monochromaticity, and good coherence. The principle of laser processing technology is that the laser light emitted by the laser generator is converted and focused by the lens to obtain a highly parallel columnar or strip-shaped beam. The extremely high energy density is obtained and concentrated into a small area on the processing material. After absorbing the energy of laser irradiation, the material heats up rapidly in a very short time and undergoes a series […]

Research status and application of laser processing technology in marine engineering

Application of laser cutting technology in marine engineering There is a huge demand for metal cutting in the field of marine engineering. The traditional metal cutting technologies are high-speed oxygen-flame cutting technology and plasma arc cutting technology. However, both of them have shortcomings such as slow cutting speed, large thermal deformation of the workpiece, and difficulty in ensuring product accuracy. As competition in the offshore engineering market becomes increasingly fierce and industry profits continue to decline, customers are becoming more and more strict on quality. Traditional metal cutting technology is unable to meet market demand and is gradually being eliminated by the market. The characteristics of laser determine that laser […]

Research on the application of laser processing technology in machinery manufacturing

Laser drilling Laser drilling is an important part of laser processing technology and an important link in processing workpieces. Common drilling types include fastening holes, positioning holes, etc. The quality of the holes has an important impact on the performance of the workpiece. Compared with mechanical processing, the application of laser drilling technology can improve the drilling effect, making the hole wall smoother and more rounded. In addition, compared with other processing technologies, laser drilling technology is more intelligent. In the initial stage of drilling, the hole depth and hole diameter increase greatly, but as the processing time increases, the hole depth and hole diameter increase slower. The reason for […]

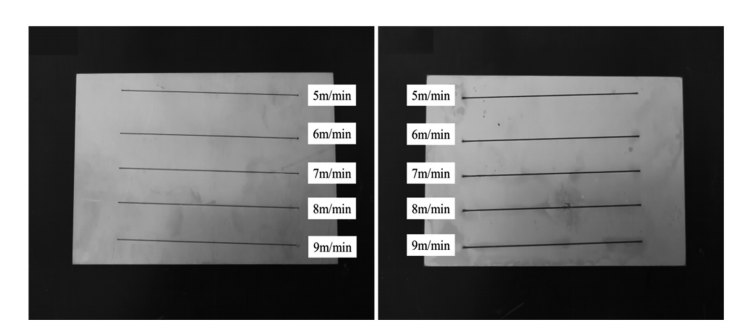

Research on laser cutting process of thin stainless steel plates

Effect of cutting gas pressure on cutting quality When laser cutting, different cutting gases are selected according to the material of the cutting plate. Nitrogen is mainly used to cut stainless steel. The selection of cutting gas and its pressure has a great impact on the quality of laser cutting. The main functions of cutting gas include: supporting combustion and dissipating heat, promptly blowing off molten stains produced by cutting, preventing molten stains from rebounding upward into the nozzle, protecting the focusing lens, etc. The experiment adopts the controlled variable method, the cutting speed is set to 8m/min, the focus position of the laser focus is -0.5mm, and the air […]

Research on laser cutting head focus control technology

The main components of the cutting head are laser cutting technology, which is a non-contact processing technology using laser as energy. It is widely used in metal cutting, automobile manufacturing, aerospace and other fields with its own advantages. The laser cutting head is a key component of the laser cutting machine. Taking the fiber cutting head as an example, its main components include fiber connection module, collimation module, focusing module, protective window module, non-contact sensor, cutting nozzle, etc. The optical fiber is connected to the cutting head from the connection module interface. The collimation module converges the divergent laser into a parallel beam, and finally focuses it into a light […]

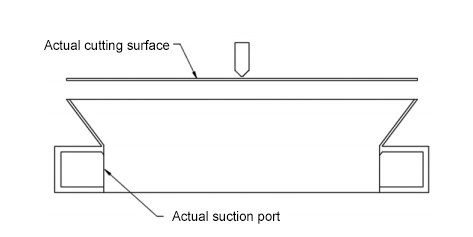

Research and Optimization of Dust Removal and Smoke Exhaust System for Laser Cutting Machines

Laser Cutting Smoke Hazards and Smoke Exhaust Mechanism Laser Cutting Smoke Hazards The smoke released when laser cutting metal plates can be roughly divided into dust and aerosols. 97% of them have a diameter of less than 5.7 μm, which means that most of the smoke can be Inhaled into the body. Depending on the cutting material and scene, other harmful substances will be produced, such as oil on the surface of the board, and very complex hydrocarbon composite gases; for example, if the surface of the board is filmed, aliphatic and olefin compounds will be released during cutting, accompanied by Distinctive odor. If the smoke and dust generated by […]

Basic principles and influencing factors of laser cutting

Laser cutting principle Laser is the product of stimulated radiation. Its production is inseparable from three key elements: working material, pump and resonant cavity. After absorbing energy, low-energy level particles will transition to high-energy level orbits, but the state of high-energy level particles is unstable and will Falling to a low-energy orbit and emitting photons at any time, laser light is generated when many particles emit photons with high consistency at the same time. Laser processing can be divided into hot processing and cold processing according to the size of photon energy. Cold processing is generally used in the laser marking process of plastic parts. The laser completes the separation […]

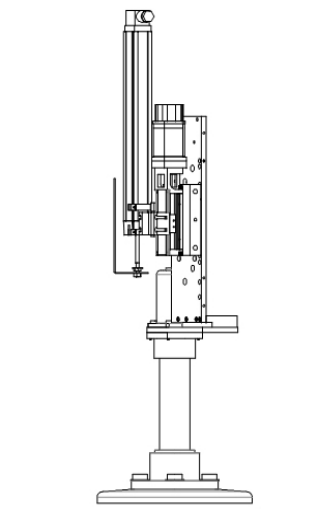

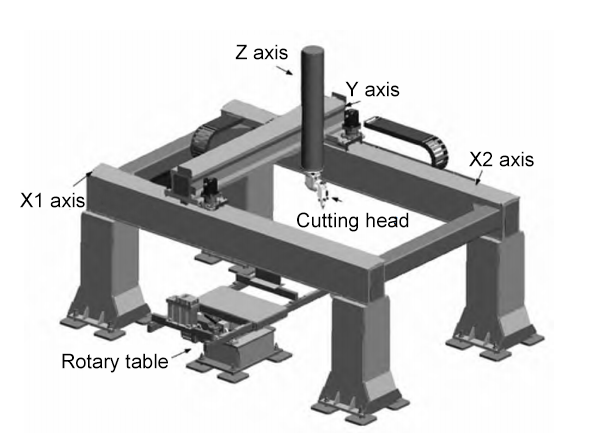

Introduction to the composition of three-dimensional five-axis CNC laser cutting machine

The development of fiber laser technology and the reduction of costs have greatly promoted the application of fiber laser in metal sheet cutting. For example, as the requirements for lightweight automobiles continue to increase, the demand for laser cutting of three-dimensional sheet metal covering parts and structural parts has gradually increased. The thickest plates among structural parts such as passenger car body panels and beams are usually within 3mm, and the product structure is complex and changes rapidly. Ordinary robot-type 3D laser cutting machines cannot fully meet the requirements of related processes in terms of accuracy, stability, efficiency, etc. and quality requirements, at this time the advantages of the three-dimensional […]