Laser cutting mechanism and evaluation index

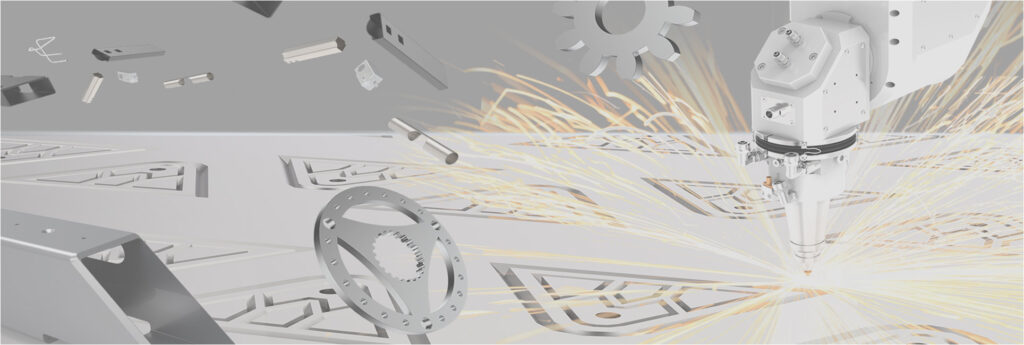

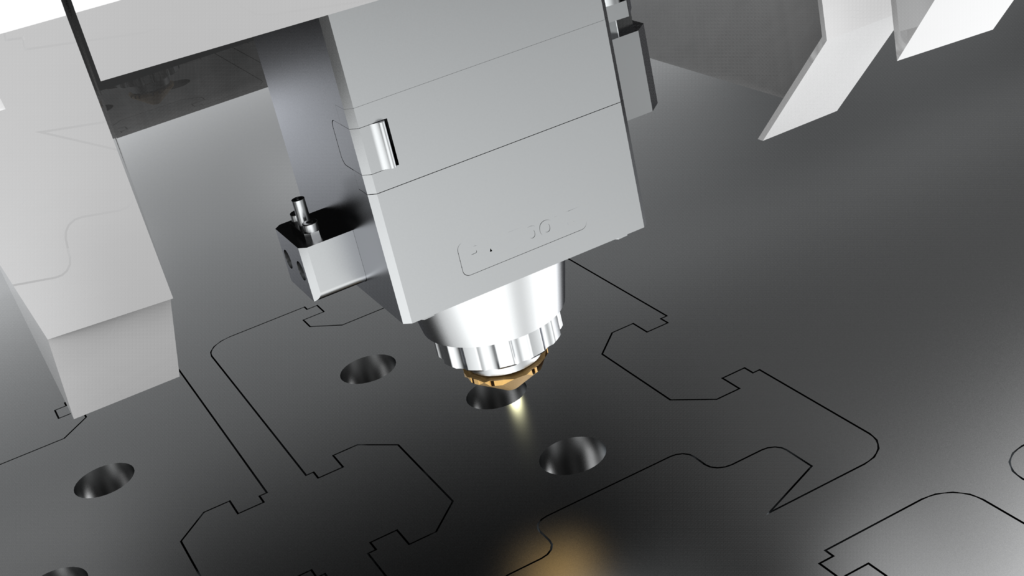

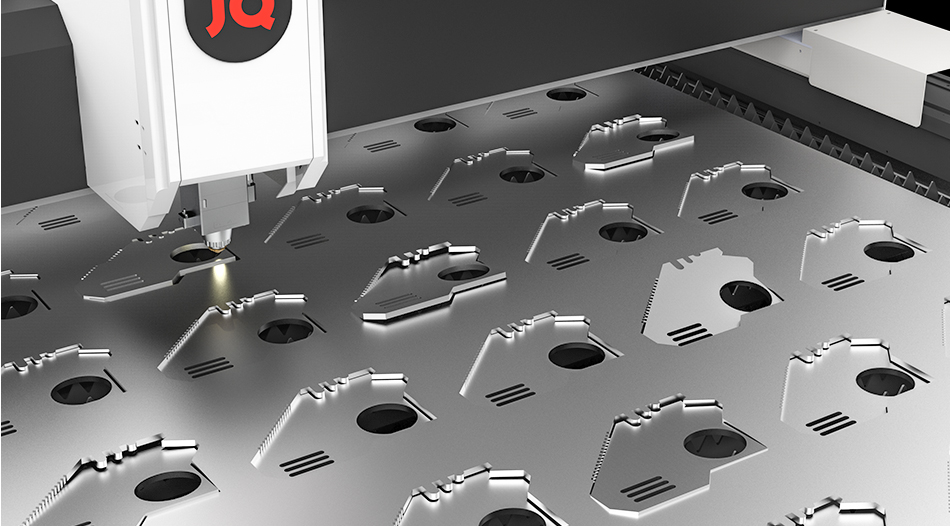

Principle of laser cutting Laser cutting is to focus the laser beam into a small spot, causing it to act on the material. The laser power density can reach more than 106 W/cm2. Under such high power density laser irradiation Under the action, the metal material quickly vaporizes and evaporates, forming holes. The molten metal residue is blown away by the high-pressure gas blown out coaxially, forming a cutting slit. The cutting head moves under a pre-designed program to cut the corresponding shape. In laser cutting, oxygen is used as an auxiliary gas, which is beneficial to the cutting of certain metal sheets. At high temperatures, oxygen will undergo an […]

Application of high-power laser cutting technology

Laser cutting principle Laser cutting uses a focused high-power, high-energy-density laser beam to irradiate onto the plate to be processed, causing the irradiated material to quickly melt, vaporize, ablate or reach the ignition point. The high-speed airflow blows away the molten material and cuts the sheet. Precautions during the production process of laser cutting equipment Equipment procurement There are many domestic laser equipment manufacturers, but there are not many leading companies that master key technologies. The purchase of large equipment must go through various forms of research, investigation and consultation. Laser power is the main factor that determines work efficiency and the ability to cut plate thickness. Therefore, laser power […]

Design of a flexible production line system for plate laser cutting

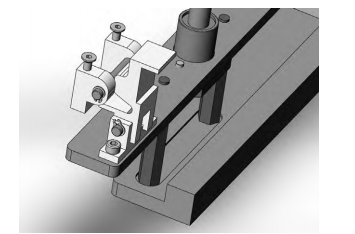

In order to improve the consistency and yield rate of products after laser cutting, it is necessary to accurately position the plates that are loaded during cutting. However, because wooden boards have a certain degree of elasticity and have large dimensional errors and are easily deformed, and the boards are stacked at random positions in the loading bin, pre-positioning is required before processing and clamping to ensure the positioning accuracy of the right-angle origin of the square boards ( (Reduce the error between workpiece coordinates and processing coordinates) and then use the robot suction cup to grab and transport it to the laser cutting machine processing area. After the loading […]

Common faults and solutions of CNC laser cutting machines

Overview of CNC laser cutting machine Laser cutting machine consists of CNC system, external optical path system, water cooling machine, cutting system and laser. When the laser cutting machine is working, it uses energy to cut metal materials, non-metal materials, composite materials, and organic materials. Laser cutting technology has many advantages, such as fast processing speed, no heating of materials, non-metallic materials will not be deformed due to heat, and higher work efficiency during processing. Common faults and solutions of CNC laser cutting machines 1 CNC laser output failure The first is that the air tightness of the air path at the laser output is reduced. Due to the reduction […]

Laser cutting technology application research on titanium alloy forgings

In the forging industry, laser cutting technology has been widely used in the flash and skin of structural steel and stainless steel forgings, while laser cutting technology on titanium alloy forgings is still a banned or restricted process in China. However, with the rapid development of laser cutting equipment, the improvement of laser equipment power and the diversification of laser cutting atmosphere have provided basic support for the high-quality application of laser cutting titanium alloy forgings. Therefore, the application research of laser cutting technology on titanium alloy forgings is more meaningful. Application research on laser cutting of titanium alloy under 3000W power and O2-assisted conditions The macro morphology of the […]

Basic principles and influencing factors of laser cutting

1 Principle of Laser Cutting Laser is the product of stimulated radiation. Its production is inseparable from three key elements: working material, pump and resonant cavity. After absorbing energy, low-energy level particles will transition to high-energy level orbits, but the state of high-energy level particles is It is unstable and will fall to a low energy level orbit at any time and emit photons. Laser is generated when many particles emit photons with high consistency at the same time. Laser processing can be divided into hot processing and cold processing according to the size of photon energy. Cold processing is generally used in the laser marking process of plastic parts. […]

Research status of laser cutting technology

Laser cutting technology is a cutting technology that uses laser to process planes. It has attracted the attention of many scholars due to its advantages such as high processing precision and no pollution. With the continuous development and progress of science and technology, people have put forward higher requirements for the performance of parts, so the methods and equipment for processing parts are constantly updated and improved. Most traditional parts are made by mechanical processing methods. Mechanical processing has shortcomings such as low processing efficiency and poor environmental friendliness. Laser processing just solves these problems. Laser cutting technology uses a laser generator to output a high-energy-density laser beam. The laser […]

Process optimization of hydraulic support structural parts based on laser cutting

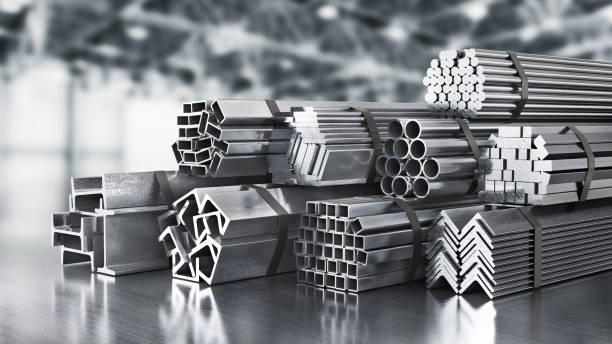

The main part of the hydraulic support is composed of structural parts of medium-thick steel plates and oil cylinders. As shown in Figure 1, the structural parts composed of medium-thick steel plates account for about 79% of the total weight of the hydraulic support. The raw materials are mainly medium-thick steel plates with a thickness of 16 mm ~ 50 mm. For the cutting of medium-thick steel plates, the traditional cutting equipment is mainly flame cutting machines and plasma cutting machines. To a certain extent, plasma and flame cutting equipment are prone to uneven shrinkage and a certain degree of thermal deformation when cutting and blanking, and kerf compensation is […]

Laser ring cutting and hole making process for laminated aluminum alloy sheets

Among laser cutting methods, there are four main cutting methods: vaporization cutting, melting cutting, oxygen-assisted melting cutting and controlled fracture cutting. This article uses the melting cutting method to make the material at the laser spot reach the melting point, and at the same time blows or removes it with the help of auxiliary gas The molten material around the hole and the scanning path are set to complete the entire test process. Laser material processing systems mainly include lasers, optical path shaping and transmission systems, motion trajectory control and operating systems, among which lasers are the most important. The laser consists of three parts: the laser medium, the pump […]

Application of laser cutting technology in marine engineering construction

Laser technology is a remarkable achievement in the science and technology industry in the middle and late part of the last century. Its emergence has greatly promoted the progress of human civilization in various industries. In various fields, laser technology has been widely used in recent years, and its application in the offshore engineering and construction industry is also closer to the front line of production. At present, there are mainly four types of plate cutting in the offshore engineering and construction industry, namely flame cutting, plasma cutting, water cutting, and laser cutting. Among them, flame cutting is mostly used in the cutting of medium and thick plates, water cutting […]