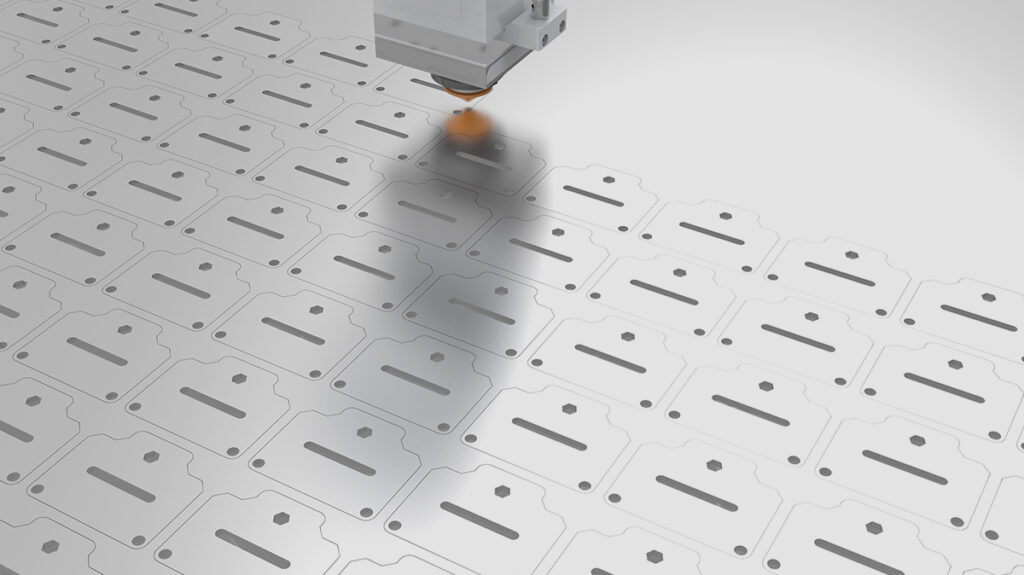

25mm thick carbon steel laser cutting process

Q235B steel is one of the most common steel materials in China, with certain strength, elongation, and good toughness and castability, easy to stamping and welding. Medium plate Q235B steel is widely used in engineering machinery, bridge construction, high-voltage transmission towers, shipbuilding, heavy machinery and large pressure vessels and other industries. In recent years, along with the rapid development of the above industries, the demand for a diversity of changes in these industries, these industries in the parts of many specifications, diverse shapes, some of the higher precision requirements, the traditional processing methods to limit its development. Laser cutting has outstanding advantages such as easy operation, non-contact, high flexibility, high […]

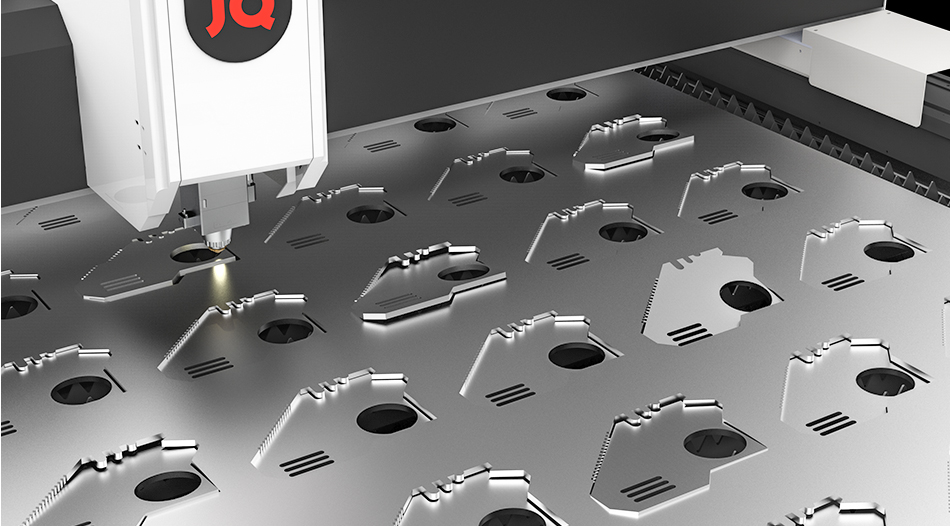

Introduction of robot laser cutting automated production line

1 System composition The production line mainly consists of a feeding system and a discharging system.system, intermediate beam, robot system, laser cutting unit, robot baseSeat, waste collection system, dust removal system, cutting protection room, pneumatic systemand electrical control system.The feeding system includes a feeding rack, a feeding trolley, and a feeding supportRoller and ground pressing device.The discharging system includes a grounded pressing device, a blanking support roller, a blankingDriving roller, slag removal system, back gauge device. 1.1 Send the feeding rack The feeding frame is made up of three sections and is connected with the feeding support roller.Installed side by side, it is the horizontal traveling bracket of the servo […]

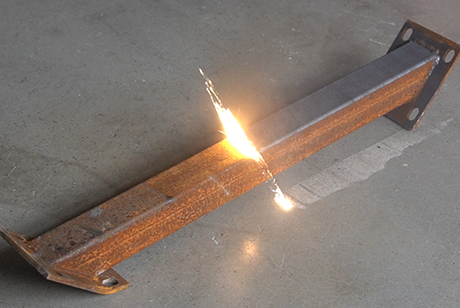

Application of laser cutting technology in hydraulic supports

Hydraulic supports are key equipment for fully mechanized mining working faces in coal mines. It plays important roles such as road support and working face support, and at the same time prevents coal lumps, gangue Stones fall onto the mining working face and scraper conveyor to ensure smooth mining. Provide security. The main part of the box structure is mainly composed of top Plate, main floor plate, reinforced plate, transverse floor plate, cover plate, ear plate, side sealing plate and other steel Plate parts are made of tailor-welded parts, and the part cutting technology plays an important role in production quality and efficiency. Rate and cost play a decisive role. […]

Laser Welding vs. MIG Welding: Understanding the Difference and Benefits

Introduction: Embracing Modern Welding Techniques In the realm of manufacturing and construction, the utilization of cutting-edge welding techniques has become pivotal in ensuring superior structural integrity and efficiency. Laser welding and MIG (Metal Inert Gas) welding stand out as two prominent methods revolutionizing the welding industry, each with its unique features and applications. Understanding the distinctions and benefits of these methods is vital for industries seeking to enhance their production capabilities and ensure top-notch weld quality. Laser Welding: Precision and Versatility in Manufacturing Laser welding, a state-of-the-art technique, has gained significant traction in various industries due to its unparalleled precision and versatility. By harnessing the power of focused light beams, […]

Is Laser Welding Strong?

Exploring the Durability and Applications of Laser Welding Technology Laser welding has emerged as a prominent technique in modern manufacturing and construction processes. With its precise and efficient methodology, it has revolutionized the way materials are joined in various industries. This article delves into the strength of laser welding and its significance in today’s industrial landscape, shedding light on its applications, advantages, and potential limitations. Understanding the Fundamentals of Laser Welding Laser welding, a non-contact process, employs a high-intensity laser beam to fuse materials together. This technology facilitates the creation of strong, high-quality welds by meticulously heating the workpiece, allowing for controlled and precise melting. Its capacity to generate deep […]

Application and Important Role of Light Curtain Protection in Laser Cutting Machines

In the ever-evolving landscape of manufacturing, technological advancements are the driving force behind increased productivity, efficiency, and safety. Laser cutting machines have emerged as powerful tools in various industries, from automotive manufacturing to medical device production. Alongside their capabilities, safety concerns have also arisen. This article explores the application and crucial role of light curtain protection in laser cutting machines, ensuring both worker safety and optimal machine performance. Introduction Laser cutting machines have revolutionized precision cutting and engraving processes across various industries. However, with great power comes the need for enhanced safety measures. This is where light curtain protection steps in, playing a vital role in safeguarding both the operator […]

Overcoming Edge Inaccessibility: Strategies for Precision Laser Metal Cutting

In today’s world of manufacturing and engineering, precision is key. When it comes to laser metal cutting, achieving precision can be challenging, especially when dealing with edges that are hard to access. This article will delve into the various strategies and techniques that can be employed to overcome edge inaccessibility in laser metal cutting processes. From advanced technology to innovative approaches, we will explore how manufacturers are pushing the boundaries of precision in this vital industrial process. 1. Introduction: The Importance of Precision in Metal Cutting Precision is the cornerstone of modern manufacturing. Whether it’s crafting intricate components for aerospace or creating precise parts for medical devices, the ability to […]

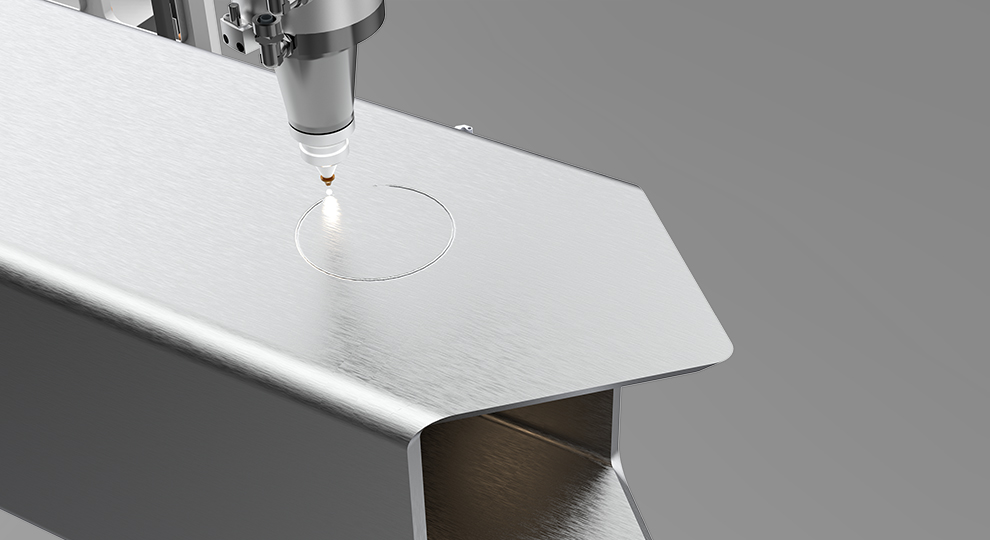

Boost Your Metal Fabrication Efficiency with Tube Laser Cutter: A Complete Guide

Metal fabrication is a crucial process in various industries, and maximizing efficiency is essential for businesses to stay competitive. One technology that has revolutionized the metal fabrication industry is the tube laser cutter. In this comprehensive guide, we will explore how tube laser cutters can boost your metal fabrication efficiency and provide you with everything you need to know about this advanced cutting method. Introduction Metal fabrication efficiency is a top priority for manufacturers and fabricators. Streamlining the production process, reducing waste, and improving precision are key factors in achieving success in the industry. Tube laser cutters have emerged as a game-changing technology, offering numerous benefits over traditional cutting methods. […]

Unleashing the Power of Precision Cutting: Tube Laser Cutter for Superior Results

Introduction In today’s rapidly evolving industrial landscape, precision cutting plays a pivotal role in various sectors. One such cutting-edge technology that has gained significant prominence is tube laser cutting. With its ability to deliver superior results, tube laser cutting has revolutionized the way we process and shape tubes for a multitude of applications. In this article, we will delve into the intricacies of tube laser cutting, exploring its advantages, applications, and factors to consider when choosing the right tube laser cutter. Understanding Tube Laser Cutting Technology What is Tube Laser Cutting? Tube laser cutting is a state-of-the-art technique that utilizes laser technology to precisely and accurately cut tubes of various […]

Maximize Productivity and Precision with Tube Laser Cutter: Expert Tips and Techniques

Tube laser cutting has revolutionized the manufacturing industry by offering enhanced precision and efficiency in cutting various materials. Whether you’re working with stainless steel, aluminum, or other alloys, a tube laser cutter can help you achieve exceptional results. In this article, we’ll delve into the world of tube laser cutting, providing expert tips and techniques to maximize productivity and precision. Introduction In today’s fast-paced manufacturing landscape, precision and productivity are key factors in ensuring success. Tube laser cutting, also known as laser tube cutting, has emerged as a cutting-edge technology that meets these demands. By utilizing a high-powered laser, tube laser cutters can precisely cut complex shapes and designs on […]