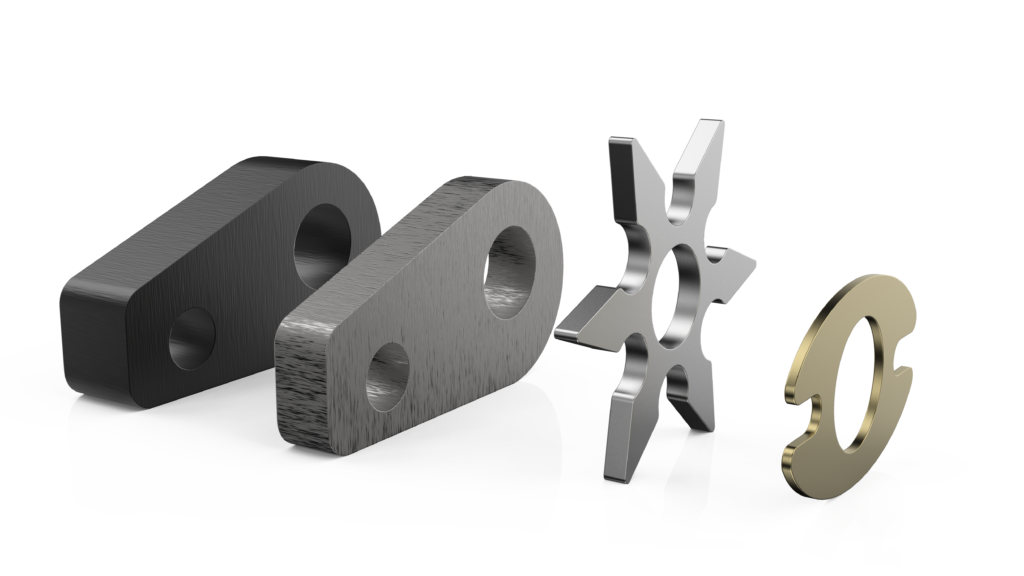

Application of laser technology in steel cutting and processing

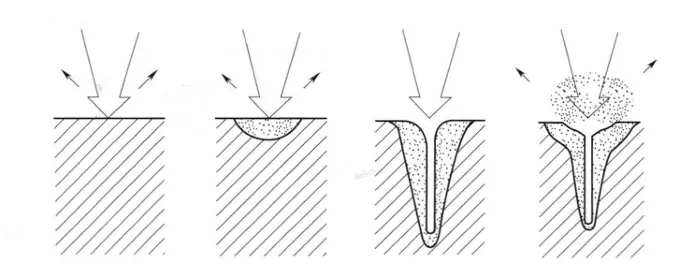

Laser Technology Principle Laser Generation and Characteristics Laser is a highly coherent and monochromatic light beam generated by stimulated radiation. The generation mechanism of laser involves atoms or molecules jumping from a low energy level to a high energy level under the action of external energy (such as electric current, light or chemical reaction), and releasing photons when returning to the low energy level. These photons are reflected by the optical resonator and resonate with other atoms, eventually forming a high-intensity coherent light beam. Laser beams have unique characteristics such as monochromaticity, coherence and high directionality, which give them unique advantages in industrial cutting and processing. Monochromaticity ensures the energy […]

The significance of the plate cutting machine to form complex bevels in one cut

Plate cutting machines have become indispensable tools in modern manufacturing, particularly in industries that require precise and efficient cutting of metal components. One of the most significant advancements in this field is the ability of these machines to create complex bevels in a single cut. This capability not only enhances the quality of the finished product but also streamlines production processes. This article explores the importance of plate cutting machines in forming complex bevels, highlighting their benefits and applications. 1. Understanding Bevel Cutting Bevel cutting refers to the process of cutting an edge of a material at an angle other than 90 degrees. This technique is crucial for preparing edges […]

Maximizing Precision: The Power-Thickness Equation in Laser Cutting

Laser cutting technology has revolutionized the manufacturing industry, providing precise and efficient methods for cutting various types of metals. One of the most critical factors influencing the effectiveness of laser cutting is the relationship between the power of the laser and the thickness of the metal being cut. Understanding this relationship is essential for optimizing cutting processes and achieving high-quality results. 1. Understanding Laser Power Laser power, measured in watts (W), is a key determinant of a laser cutting machine’s capability. Higher power levels allow for faster cutting speeds and the ability to cut through thicker materials. By understanding how laser power affects cutting capabilities, operators can select appropriate machines […]

Winter Maintenance and Care of Laser Cutting Machines

Winter presents unique challenges for laser cutting machines, especially in regions that experience extreme cold. Proper maintenance and care during this season are essential to ensure optimal performance and longevity of the equipment. This article outlines key strategies for winter maintenance and care of laser cutting machines, focusing on preventing damage from freezing temperatures and ensuring reliable operation throughout the colder months. 1. Understand Operating Temperature Requirements Maintaining the appropriate operating temperature is crucial for the efficient functioning of laser cutting machines. Ideally, these machines should operate in an environment where the temperature is around 22°C. However, during winter, temperatures can drop significantly, which can lead to various operational issues. […]

Research on laser welding forming control technology——Principle and characteristics

Mechanism and control technology principles and characteristics of laser welding The development trend and characteristics of modern vehicles are high-speed operation and lightweight structure. Therefore, higher requirements are put forward for the manufacturing of key structures, such as lightweight, integration, high reliability, long life and low-cost green manufacturing. To this end, high-energy beam welding with high-strength and lightweight titanium alloys, aluminum alloys and other typical structural materials and high-energy density beam as welding heat source to manufacture the overall structure has become one of the advanced manufacturing technology achievements that conform to this development demand. With many advantages, high-energy beam welding manufacturing is known as a new technology with revolutionary […]

レーザー切断とレーザークラッディングの比較

Laser cutting is a modern manufacturing process that utilizes focused light energy to cut through various materials with high precision. The term “laser” stands for “light amplification by stimulated emission of radiation,” which describes how lasers work by concentrating light to produce extreme temperatures that melt or vaporize materials. This technology has transformed traditional manufacturing methods, offering a level of accuracy and efficiency that was previously unattainable.Laser cutting operates by directing a high-powered laser beam onto the material surface, which either melts or vaporizes the material, allowing for clean cuts. The process can be adjusted for different thicknesses and types of materials, making it incredibly versatile. Industries ranging from automotive […]

チューブ曲げ加工前のチューブレーザー切断の重要な役割

In metal fabrication, tube laser cutting is crucial before the bending stage. This technique not only cuts but also ensures precision and quality in later processes. Tube laser cutting enables detailed designs and clean edges, which help maintain the tubes’ strength and appearance during bending.The importance of tube laser cutting is significant. With laser technology, manufacturers achieve greater accuracy, less material waste, and improved efficiency. This method allows for complex shapes that traditional cutting cannot easily produce. Consequently, businesses can better meet market demands by creating customized products that fulfill specific customer needs. The Advantages of Tube Laser Cutting Tube laser cutting offers many benefits. This technology provides precision that […]

レーザー加工機の品質検査を購入する必要はありますか?

Key Considerations in Laser Cutting Machine Quality Inspection Factor Description Importance Inspection Frequency Determines how often inspections should be performed to maintain optimal machine function. Regular inspections prevent wear and tear, keeping productivity high and minimizing unexpected costs. Precision and Calibration Ensures the machine operates with optimal precision, essential for industries requiring tight tolerances. Calibration improves accuracy, reducing errors and material waste. Component Wear Assesses wear on critical machine components, such as lenses and mirrors, that can affect laser quality. Regular checks prevent expensive component failures and downtime. Safety Standards Ensures machine meets required safety standards to protect operators and maintain workplace safety. Compliance with standards avoids fines and ensures […]

プラットフォームや独立したサイトからレーザー切断機のサプライヤーを探す際に注意すべきこと

When you’re in the market for a laser cutting machine, finding a reliable supplier can make or break your purchase. Online platforms and supplier directories offer a wide range of suppliers, but navigating these options effectively requires attention to key details. Here’s a comprehensive guide to help you find the perfect laser cutting machine supplier, ensuring you get the best value for your money and avoiding common pitfalls. 1. “5 Things You Must Know When Searching for a Laser Cutting Machine Supplier Online” When browsing platforms like Alibaba, eBay, or industry-specific websites, knowing how to assess a supplier is crucial. The first five key factors to consider when sourcing laser […]

購入前に知っておくべきレーザー切断機の保証の秘密

When purchasing a laser cutting machine, the cost of the machine itself is a significant investment, but another equally important factor is the warranty that comes with it. Choosing the right warranty can save you from expensive repair bills and downtime, but navigating the terms and conditions can be tricky. Here’s what you need to know to make an informed decision when buying a laser cutting machine warranty. Understanding What’s Covered in a Laser Cutting Machine Warranty Most warranties cover the core components of the laser cutting machine, such as the laser source, power supply, and the control system. However, different manufacturers offer various levels of coverage, and it’s crucial […]