Tube Laser-Cutting: A Streamlined Construction Process

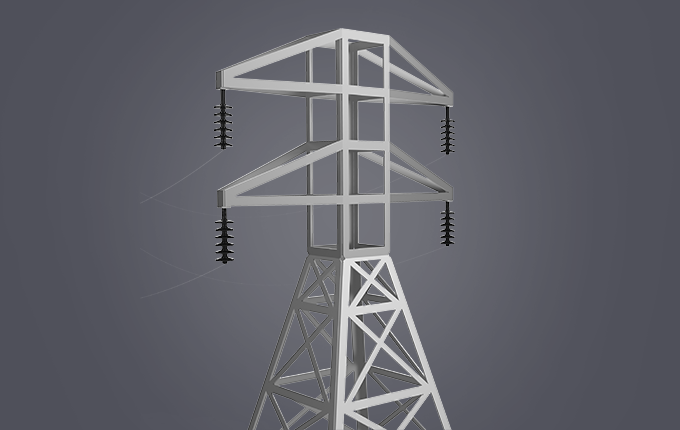

Introduction Tube laser-cutting is a process that has revolutionized the design and manufacturing sector. With its ability to streamline complex cutting tasks, improve accuracy, and increase efficiency, this technology has become an invaluable tool in the industry. In this article, we explore the benefits of tube laser-cutting, how it streamlines construction, how it advances design and manufacturing, how it enhances quality standards, and how it maximizes efficiency. Exploring the Benefits of Tube Laser-Cutting Tube laser-cutting is widely used in a range of sectors and industries, including automotive, construction, and engineering. The technology offers a range of key benefits that make the process incredibly advantageous. The Technology Behind Tube Laser-Cutting This […]

What is a laser tube used for?

Lasers are a powerful tool with a wide range of applications, from medical treatments to manufacturing processes. In order to produce the laser beam, a laser tube is often used. A laser tube is an essential component for many laser systems because it helps to generate and regulate the power of the beam. This article will provide an overview of what a laser tube is and explain its purpose in detail. What is a Laser Tube? A laser tube is a device used in various applications from industrial cutting, welding and marking to medical uses such as laser surgery. It consists of active medium gain material encapsulated in a sealed […]

How to open up new design possibilities with tube laser cutting machines

What is Tube Laser Cutting? Tube laser cutting is a revolutionary process that allows for the manufacture of complex shapes and designs in metal tubing. This cutting technique offers many advantages over traditional methods, such as improved speed and accuracy. It also opens up new design possibilities for manufacturers, allowing them to create intricate shapes in materials like steel, aluminum, copper, and titanium with ease. Tube laser cutting machines use a combination of lasers and computer-aided design (CAD) systems to cut through metal tubes with precision. A high-powered laser is focused onto the tube material to penetrate it quickly and accurately while at the same time leaving a clean finish. […]

Unlimited guide of tube laser cutting

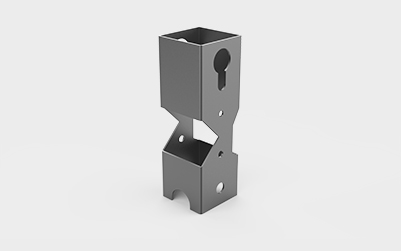

Tube laser cutting has become a popular and efficient way of cutting, drilling and welding various materials in the manufacturing industry. It offers a number of advantages compared to traditional methods, including flexibility, precision, speed and cost-effectiveness. This article provides an unlimited guide to understanding the basics of tube laser cutting technology and its applications. We will look at how this process works, why it is becoming so popular, and explore some of the key benefits that it brings to businesses across different industries. What is Tube Laser Cutting? Main components of the product Tube laser cutting technology is one of the most versatile and efficient methods for fabricating complex […]

How to choose a tube laser cutting system to optimize production

Introduction Choosing the right tube laser cutting system is essential for optimal production. With the right system, you can maximize efficiency, accuracy, and cost savings. This guide will provide an overview of the factors to consider in selecting a tube laser cutting system, including the type of tube you are using, the size and shape of the material, and the production needs of your business. You’ll also learn about the different types of laser cutting systems available, and the benefits and drawbacks of each. With this information, you’ll be able to make an informed decision and find a system that will best meet your production needs. What to Look for […]

Tube laser cutting machine: mainly used for cutting various metal hollow round tube materials

Introduction Tube laser cutting machine is a modern cutting technology used for cutting various metal hollow round tube materials such as aluminum, copper, brass, and steel. It is a precise, high-speed, and cost-effective cutting method that is used in a variety of industries. The laser beam is focused on the tube to be cut and the material is cut with high precision and accuracy. The laser beam is directed and focused on the material to be cut, which is then melted and vaporized due to the extreme heat. The end result is a precise, clean, and smooth cut. The laser tube cutting process also eliminates the need for secondary machining, […]

The effect of laser cutting parameters on the formability of complex phase steel

Complex Phase Steel Formability of Steel Complex phase steel is a type of high-strength low-alloy steel that has been developed to meet the needs of industry. It is known for its excellent formability and strength, making it ideal for applications such as automotive body parts and building components. Recent research has shown that laser cutting parameters can have an effect on the formability of complex phase steel, which can in turn influence how well products made from this material perform. This article will investigate the effects of different laser cutting parameters on the formability of complex phase steel, as well as their implications for design and manufacturing processes. The findings […]

How to improve your tube beam laser cutting skills: the basics to know

Introduction Tube beam laser cutting is one of the most versatile and efficient methods of cutting materials in today’s industrial world. If you’re looking to improve your skills in this area, there are a few basics to know. In this guide, we’ll cover the basics of tube beam laser cutting, including the different types of materials that can be cut, the safety measures to keep in mind, and the best practices for achieving high-quality cuts. We’ll also discuss tips and tricks to help you develop your skills and get the most out of your laser cutting machine. By the time you’re done, you’ll have a better understanding of how to […]

How to improve tube laser cutting parts

Introduction Tube laser cutting parts are used in many industries and are essential for many projects. With the advancements in laser cutting technology, it is now easier than ever to produce high-quality parts. This article will provide tips on how to improve tube laser cutting parts. By following these tips, you can get better results from your laser cutting machine and produce parts of higher quality. We will discuss topics like proper machine setup, material selection, and the best cutting parameters. We will also provide some examples of how laser cutting can be used to improve parts. With the right knowledge, you can maximize the efficiency and accuracy of your […]

Factors affecting laser cutting tailing

Introduction Laser cutting is a widely used process for cutting or engraving materials. It is a highly precise process that produces clean and accurate cuts, but it is not without its flaws. Laser cutting tailing is a common issue in laser cutting that can cause inaccuracy and inconsistency in the cut pieces. It is important to understand what factors can affect laser cutting tailing in order to produce the best possible results. This article will explore the various factors that can affect the amount of tailing in a laser cutting process, including laser beam power and focus, speed of the cutting process, and the material being cut. How Does Beam […]