How Laser and TIG Welding Harmonize in Today’s Job Shops

In the modern job shop, laser and TIG welding coexist as complementary techniques, each offering unique advantages that cater to different needs within the fabrication process. The integration of these two methods allows job shops to maximize efficiency, precision, and versatility, addressing a wide range of welding requirements.Laser welding is renowned for its precision and speed. It uses a focused laser beam to join materials, creating a small heat-affected zone and allowing for high-quality welds with minimal distortion. This method is particularly advantageous for applications requiring tight tolerances and high-speed production, such as in the aerospace, electronics, and automotive industries. On the other hand, TIG welding, which stands for Tungsten Inert […]

Laser Welding vs. TIG Welding

Laser welding and TIG (Tungsten Inert Gas) welding are two prominent techniques used in the metalworking industry, each with its own set of advantages and applications. Understanding the differences between these methods can help manufacturers choose the right technique for their specific needs.Laser welding is a high-precision technique that uses a laser beam to join metals. It is known for its speed, accuracy, and ability to weld hard-to-reach areas with minimal distortion. This method is ideal for applications requiring high-quality welds and is commonly used in the automotive, aerospace, and electronics industries. Laser welding provides a concentrated heat source, allowing for narrow, deep welds and high welding rates.On the other […]

The Crucial Role of Laser Cutting Safety: Protecting Your Workforce and Business

The Importance of Laser Cutting Safety Laser cutting is a highly efficient and versatile technology used in various industries, from manufacturing to art. However, the importance of laser cutting safety cannot be overstated. Ensuring a safe working environment is crucial to prevent accidents and health hazards associated with laser operations.Laser cutting involves high-powered lasers that can pose significant risks if not handled properly. These risks include eye injuries, skin burns, and respiratory issues due to fumes and particulates. Therefore, implementing comprehensive safety measures is essential to protect workers and maintain a safe workspace. Laser Cutting Safety Information Aspect Details Eye Protection Use laser safety goggles appropriate for the laser’s wavelength. […]

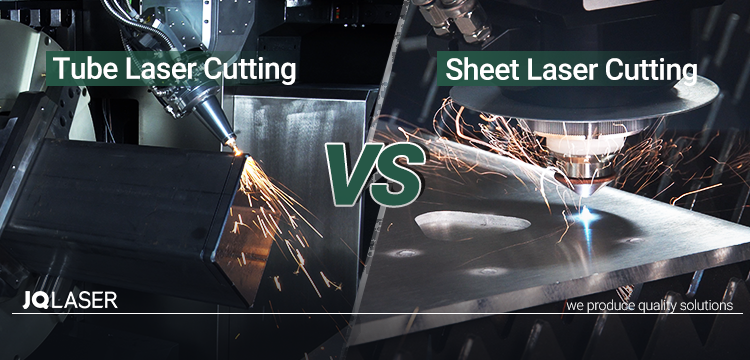

Why Tube Laser and Sheet Metal Cutting Speeds Differ

The speed difference between tube laser cutting and sheet metal cutting is a topic of significant interest in the manufacturing industry. While both technologies utilize laser cutting, their applications and efficiencies differ due to the inherent complexities of the materials and shapes they handle. Complexity of Tubular Workpieces One of the primary reasons tube lasers operate at slower speeds compared to sheet metal cutters is the complexity of the workpieces involved. Tubes often have varying thicknesses, weld seams, and differing corner radii, which require more precise handling and slower cutting speeds to maintain quality. In contrast, sheet metal is typically flat and uniform, allowing for faster processing speeds.In tube laser […]

The Revolutionary Sheet Metal Laser Cutting Process

Sheet Metal Laser Cutting Process Sheet metal laser cutting is a thermal cutting process that uses highly concentrated beams of light (lasers) to melt or vaporize materials until the desired shape is achieved. This technique is renowned for its precision, speed, and versatility, making it a preferred method for cutting various metals, alloys, and even non-metals.The process operates on computer numerical control (CNC) technology, which ensures impeccable precision. Before the cutting operation begins, the operator inputs codes or programs detailing the designs or patterns into the computer. The laser cutting machine then follows these instructions to cut the material with extreme accuracy. Bio Data and Personal Information Table Category Details […]

Laser welding process and principle

Welding Processes and Principles 1.1 Definition of Welding Welding is the process of joining two or more materials, either similar or different, by creating atomic or molecular bonds through heating, applying pressure, or a combination of both. The methods used to facilitate these bonds include heating, pressing, or both simultaneously. 1.2 Classification of Metal Welding Metal welding can be categorized based on the characteristics of the process into three main types: fusion welding, pressure welding, and brazing. Fusion Welding In fusion welding, the workpieces to be joined are heated until they melt and form a molten pool. Once the molten pool cools and solidifies, the materials are joined. This process […]

Laser cleaning technology principle and application progress

With the continuous development of high-end fields such as aerospace, petrochemical, high-speed rail, weapons, and nuclear power in China, the environments in which various equipment components are located have also changed accordingly, with increasingly high requirements for the performance of metal material components. To improve overall equipment performance and extend the service life of parts, laser cleaning technology has received widespread attention and research without changing the base material.Common industrial cleaning methods include mechanical grinding, high-pressure water jet cleaning, and chemical cleaning. However, these methods have disadvantages such as low work efficiency, harsh environments, easy damage to the workpiece surface, and inability to meet high cleanliness and high precision cleaning […]

Application of laser cutting technology in mechanical processing

Laser principles and classification Lasers are laser generating devices and are widely used in medical, aerospace, machining, automotive electronics, shipbuilding and cutting-edge scientific research fields. The laser is mainly composed of three parts: pump source, gain medium and optical resonant cavity. The pump source provides energy to the laser. The gain medium absorbs the energy provided by the pump source, inverts the particle number, and provides a medium system for the light amplified by stimulated emission of radiation. The optical resonant cavity provides a space for energy excitation, which can repeatedly reflect light, enhance the excited light, and finally release the laser.According to the time domain characteristics of optical fiber, […]

The advantages of handheld laser welding machine

Handheld laser welding machines have revolutionized the welding industry by offering numerous advantages over traditional welding methods. This guide explores the key benefits of these machines, providing detailed insights into their features, applications, and overall impact on various industries. 1. Minimal Heat Input Handheld laser welding machines significantly reduce the heat input required for welding, resulting in a smaller heat-affected zone. This minimizes deformation and preserves the integrity of the workpiece. 2. High Welding Speed These machines can weld at speeds up to 10 times faster than traditional methods like TIG and MIG welding. This increased speed enhances production efficiency and reduces labor costs. 3. Precision and Control Handheld laser welders offer exceptional […]

Application of laser processing technology in mold manufacturing

With the development of science and technology, laser technology, as an advanced processing method, has been widely used in the manufacturing industry. As the basic process equipment for industrial production, the manufacturing accuracy and efficiency of molds affect the quality and production cost of products. Traditional mold parts processing methods are difficult to meet the high requirements of modern manufacturing in some aspects, and laser processing technology has gradually become a new favorite in the mold manufacturing field with its high precision, high efficiency and non-contact characteristics. Laser processing technology can not only achieve precision cutting and welding of metal materials, but also perform surface treatment and micro-processing. Therefore, laser […]